Substrate processing device

A substrate processing device and substrate technology, applied in optics, instruments, electrical components, etc., can solve problems such as uneven cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

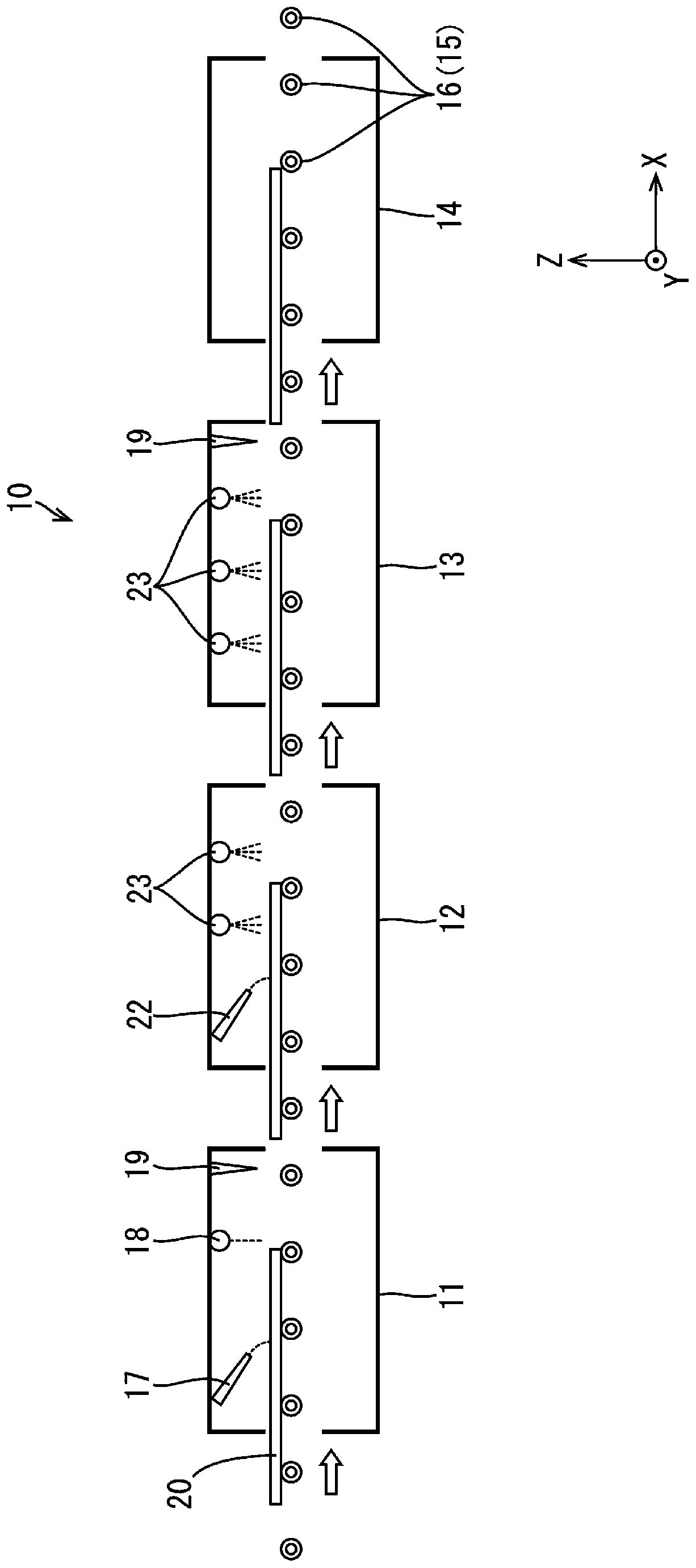

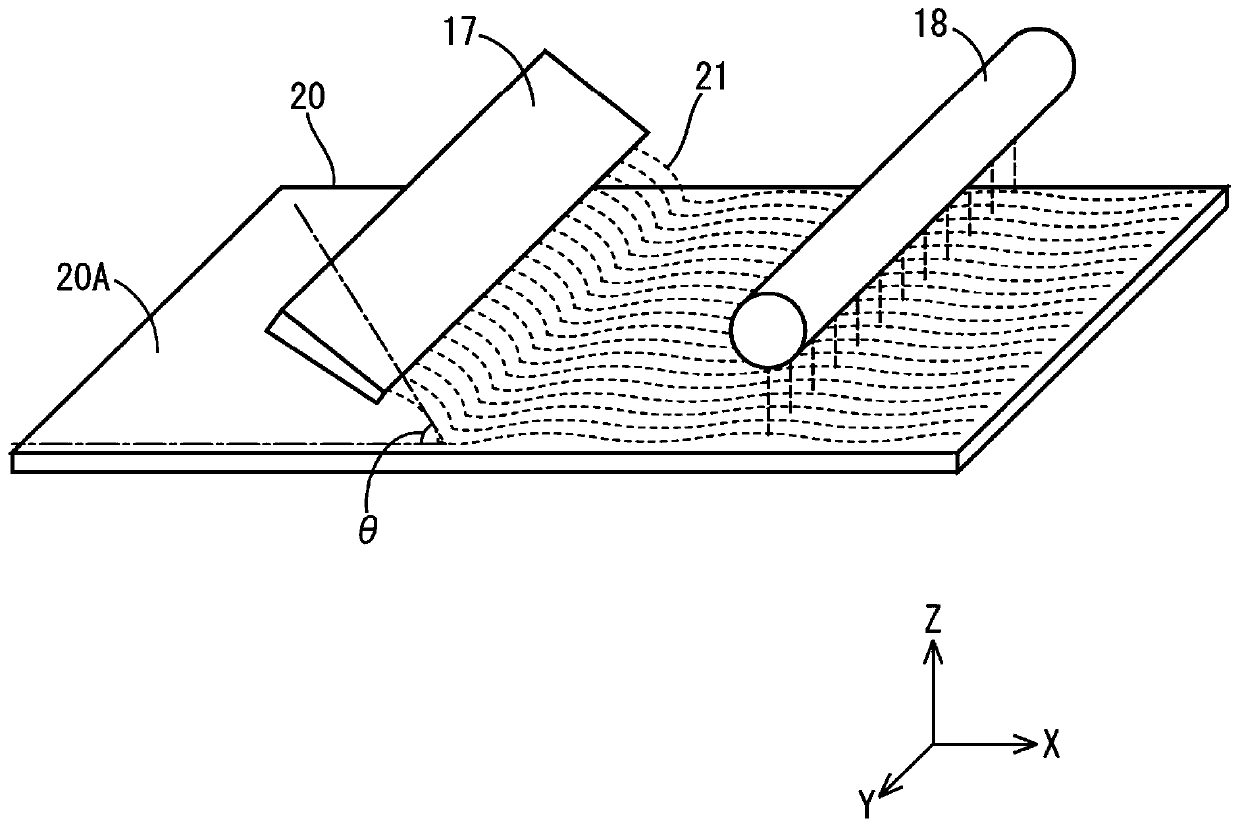

[0036] pass Figure 1 to Figure 4 The first embodiment will be described.

[0037] The substrate processing apparatus 10 of the present embodiment is an apparatus for cleaning foreign objects such as the substrate 20 for liquid crystal, such as figure 1 There are a plurality of treatment tanks as shown, wherein the liquid crystal substrate 20 is a state in which a polyimide film is subjected to orientation treatment by a rubbing method, and foreign matter such as fine dust or scratches adheres to the surface.

[0038] Also, in the following description, the figure 1 The X-axis direction in , is the transport direction (front-back direction) of the liquid crystal substrate 20, the Y-axis direction perpendicular to the paper is the left-right direction (the width direction of the liquid crystal substrate 20 being transported), and the Z-axis direction is the up-down direction. . And, will figure 1 The left side is the upstream side of the conveying direction, and the figure...

no. 2 approach

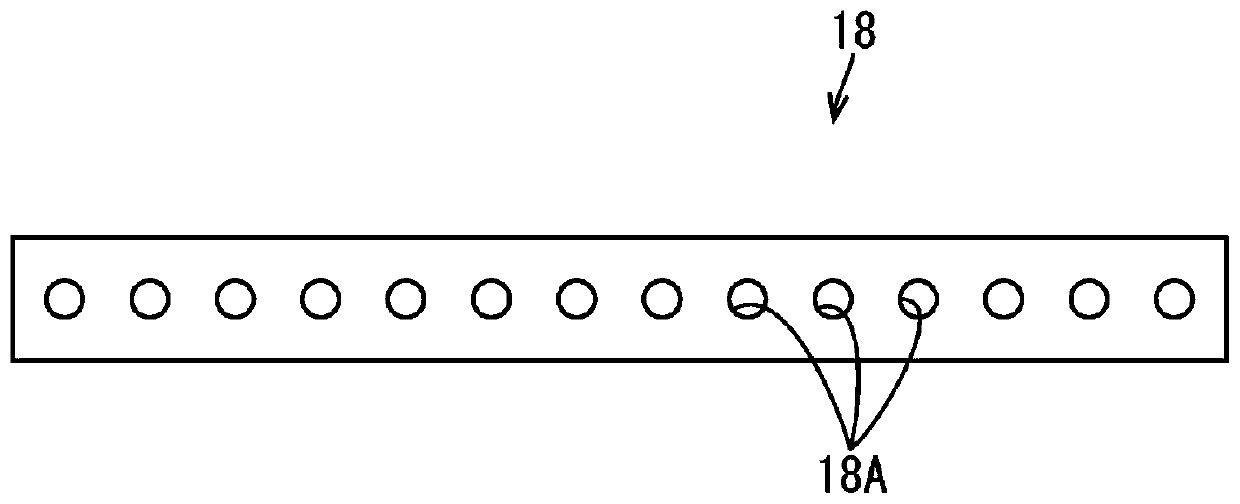

[0064] refer to Figure 5 and Image 6 A second embodiment will be described. The form of the duct shower 38 of 2nd Embodiment differs from 1st Embodiment. The other configurations are the same as those of the first embodiment, and thus the description of the entire substrate processing apparatus will be omitted.

[0065] The pipeline shower 38 of the coating treatment tank of the substrate processing apparatus of this embodiment differs from the first embodiment in the following aspects: Figure 5 As shown, a plurality of discharge holes 38A are provided in a direction (Y direction) perpendicular to the conveyance direction so as to deviate from both ends. Specifically, it is a configuration in which discharge holes 38A are provided at positions corresponding to both end sides in the width direction (Y direction) of the liquid crystal substrate 20 where the thin film of IPA 21 formed on the liquid crystal substrate 20 tends to become thinner, No discharge holes are provid...

no. 3 approach

[0069] refer to Figure 7 and Figure 8 A third embodiment will be described. The third embodiment is also different from the first embodiment in the form of the pipe shower 48 .

[0070] The pipe shower 48 of this embodiment is different from the first embodiment in the following aspects: as Figure 7 As shown, the hole diameters of the plurality of spray holes 48A of the pipe shower 48 are set such that the smaller the central part is in the direction (Y direction) perpendicular to the conveying direction, the smaller the diameter is at both ends. Gradually grow larger. That is, the discharge amount has distribution in the width direction. The intervals between the plurality of discharge holes 48A are all equal.

[0071] According to the pipe shower 48 of this embodiment, new IPA 21 can be supplied to the defective portion of the IPA film, which is formed on the entire orientation treatment surface 20A by the curtain shower 17, and The latter part of the IPA film is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com