Semiconductor component coating film processing method

A semiconductor and component technology, applied in the field of coating process of semiconductor components, can solve problems such as component leakage, invisible cutting of the back-plated surface, and cracking of wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The design method provided by the present invention is described in detail below by means of the accompanying drawings and specific examples:

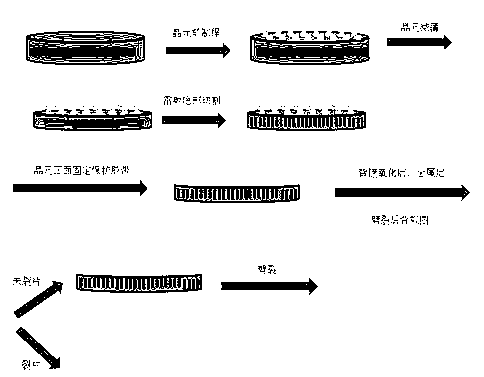

[0031] figure 1 It is a process diagram of semiconductor coating in the prior art, which includes the following steps:

[0032] 1) Thinning the wafer before the coating process;

[0033] 2) Stealth laser cutting of wafers;

[0034] 3) Fix the protective tape on the front of the wafer;

[0035] 4) Back plating oxide layer, metal layer;

[0036] 5) After the back plating is completed, the adhered and bonded substrates are peeled off;

[0037] 6) Split the unsplit pieces.

[0038] Due to the above-mentioned process, after the wafer is thinned for laser stealth dicing, the wafer is still fragile and difficult to handle only by adhesive tape, so it is prone to cracking, making the subsequent process difficult and not suitable for mass production.

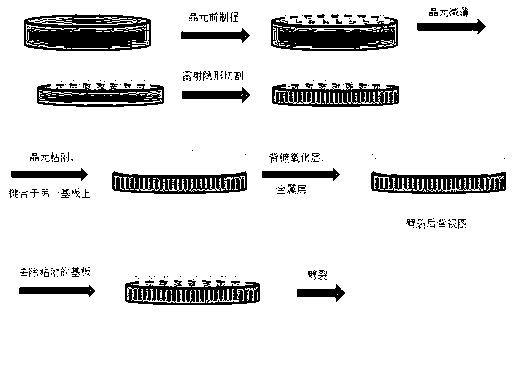

[0039] figure 2 It is a semiconductor coating process diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com