Ultrathin THz thin film circuit processing method with local metal support and thin film circuit

A thin-film circuit and metal support technology, which is applied in the direction of circuits, electrical components, and electric solid devices, can solve the problems of difficult clamping in precision assembly operations, poor mechanical strength of circuits, and poor mechanical strength of thin-film circuits, so as to meet the requirements of precision assembly operations. demand, ensure processing accuracy, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

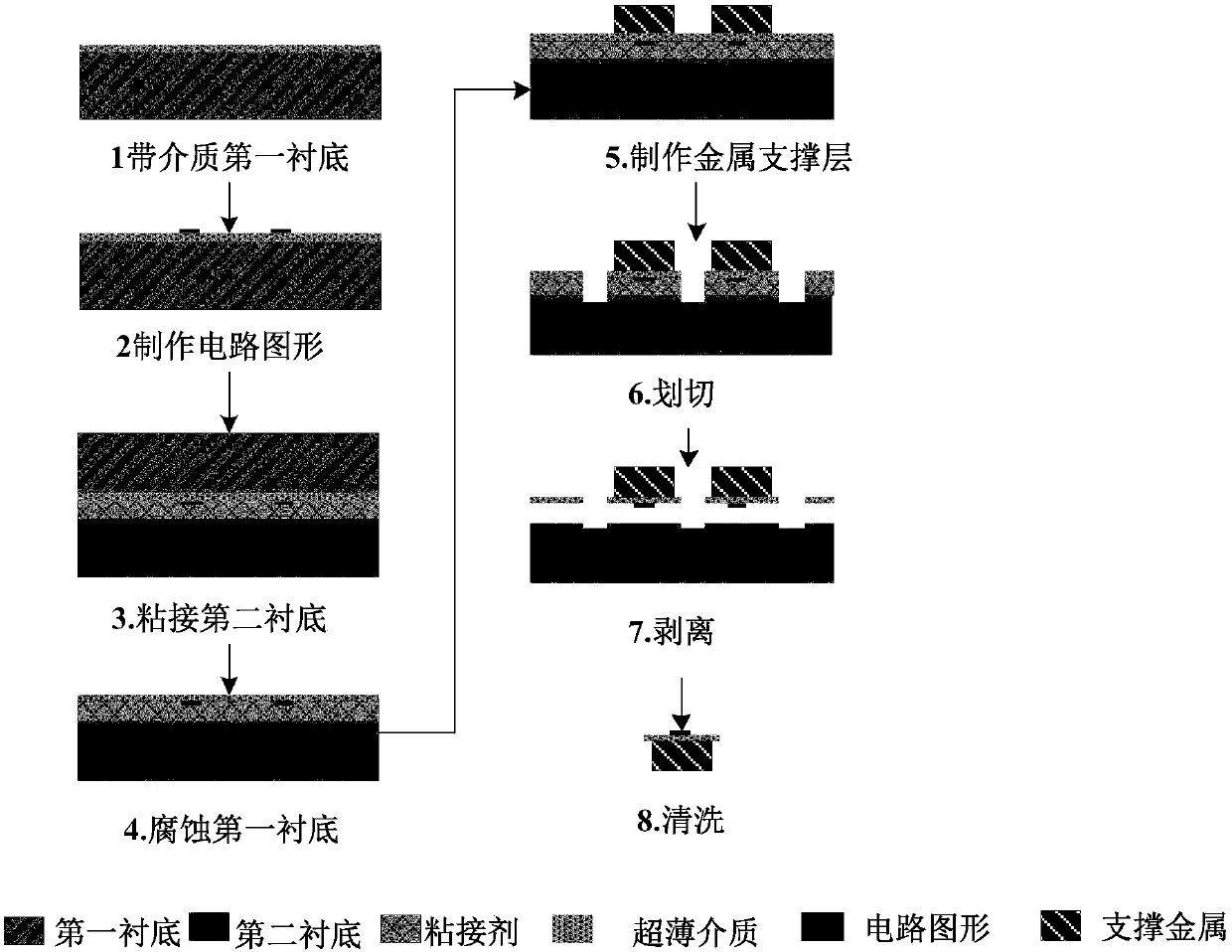

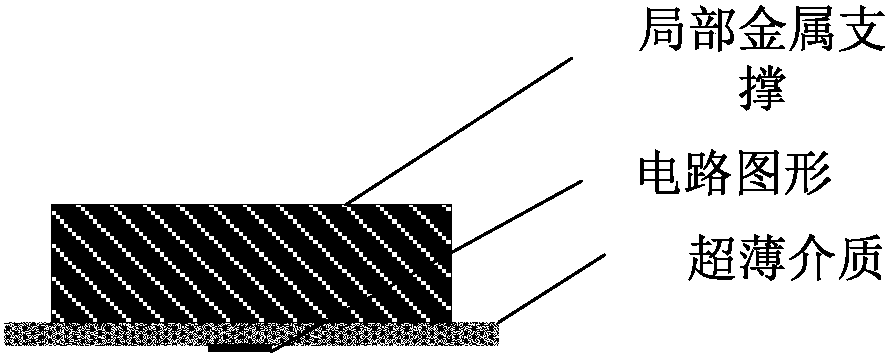

[0066] Specifically, taking the fabricated medium as polyimide, the first substrate as quartz, the second substrate as copper plate, and the locally reinforced metal support layer as the locally reinforced metal copper support layer as an example:

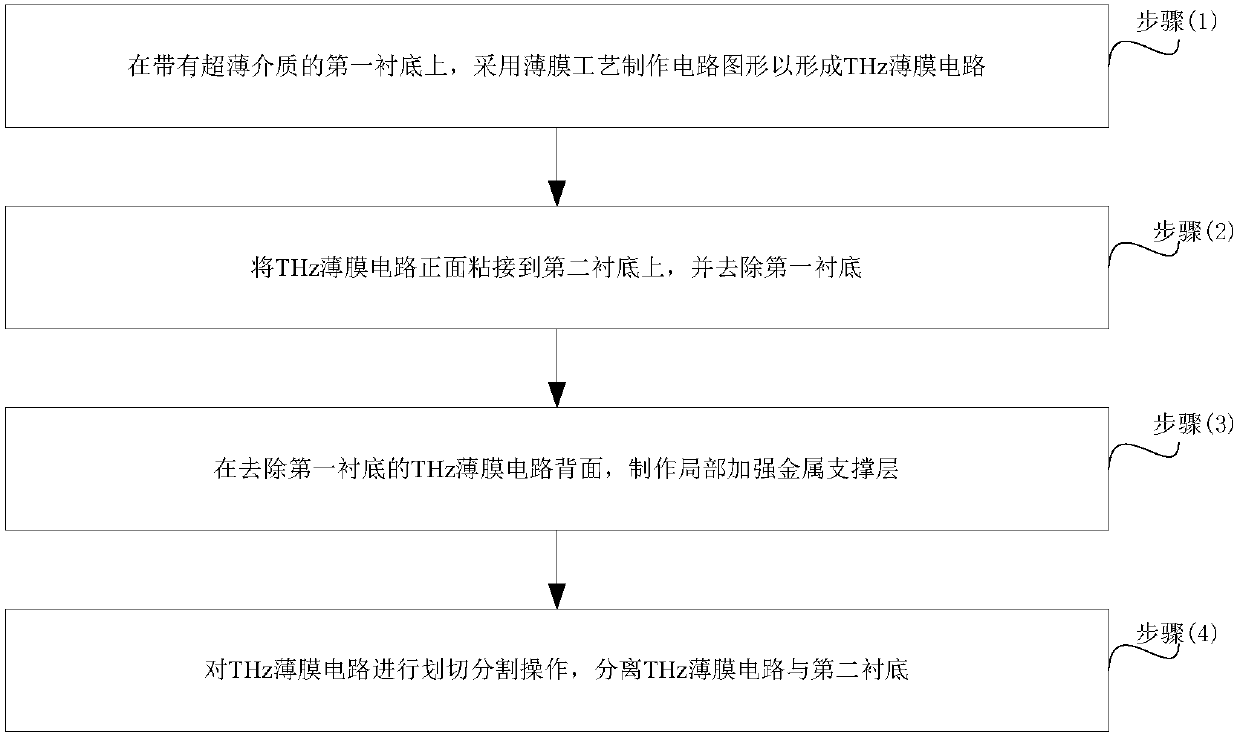

[0067] Step 1: On the first substrate with an ultra-thin dielectric, use a thin film process to make a circuit pattern to form a THz thin film circuit; wherein, in this step, polyimide is selected as the medium, and the quartz substrate is used as the first substrate The bottom, the selected quartz substrate should have a good surface finish and flatness, the thickness of the quartz is 0.254mm, and the size is 50mm×50mm;

[0068] A polyimide film is formed on a quartz substrate by spin coating;

[0069] Select 305IIB type polyimide (PI) glue, spread the glue at a speed of 500 rpm for 3 to 5 seconds, spread the glue at 1000 rpm for 25 seconds, and spread the glue at a thickness of about 10 μm;

[0070] After gluing, the polyimide f...

Embodiment 2

[0104] Specifically, taking the dielectric silicon dioxide produced, the first substrate is aluminum, the second substrate is stainless steel, and the locally reinforced metal support layer is metal gold as an example:

[0105] Step 1: On the first substrate with an ultra-thin dielectric, a circuit pattern is made by a thin film process to form a THz thin film circuit;

[0106]Among them, in this step, silicon dioxide is selected as the medium, and the aluminum plate is used as the first substrate. The selected aluminum plate substrate must have good surface finish and flatness, the thickness of the aluminum plate is 0.5mm, and the size is 60mm×60mm;

[0107] Using the method of chemical vapor deposition to form a silicon dioxide dielectric film on the aluminum plate substrate;

[0108] The thickness of the silicon dioxide dielectric is about 5 μm;

[0109] In said step 1, the technological process of making circuit graphics by thin film technology is:

[0110] Vacuum coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com