Thin film pasting device

A technology of film pasting and fixing plate, applied in lamination device, inking device, printing and other directions, can solve the problems of product quality decline, increase in manufacturing cost, low production efficiency, etc., to improve the quality, reduce the occurrence of defects and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, preferred embodiments of the film-attached package according to the present invention will be described in detail with reference to the drawings.

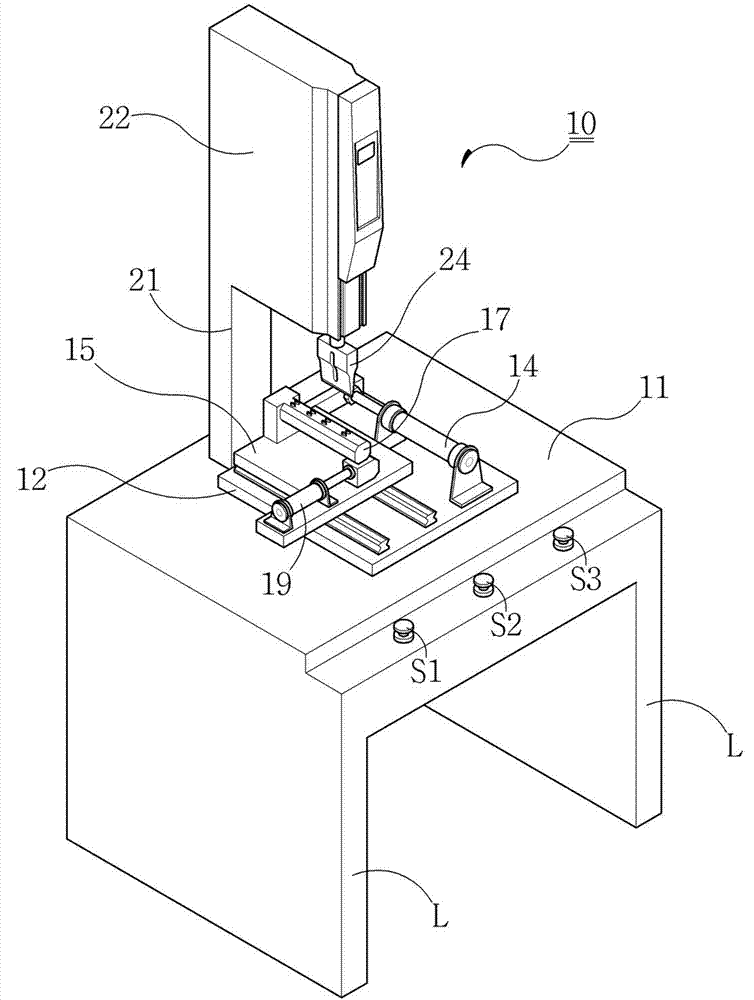

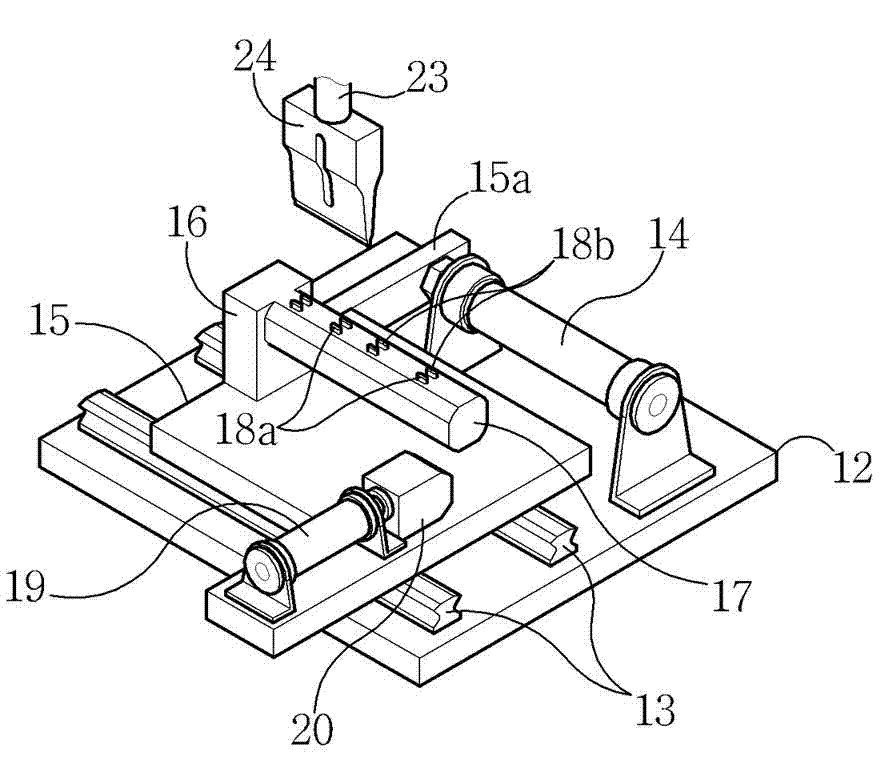

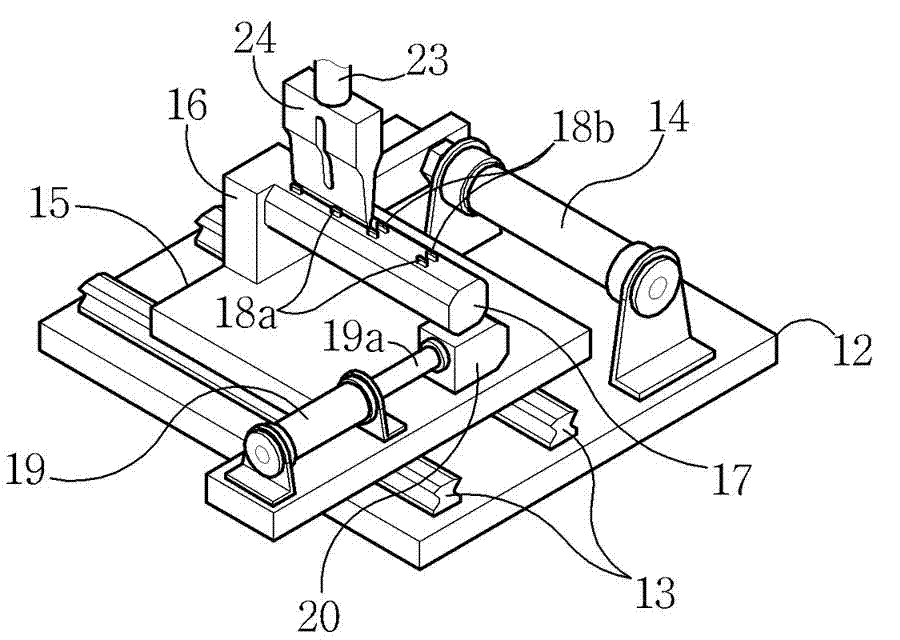

[0015] figure 1 is a preferred embodiment of the film sticking device 10 according to the present invention. Such as figure 1 As shown, the constitution of this invention is as follows. Start switch S1, S2, S3 of starting device is set on the front side of the base (11) that is supported by support leg L; On the top of the fixed plate 12 that is firmly fixed on the central part of the base 11, a moving plate 15 is set; On the fixed plate 12 Lifting cover 22 is set on the top of the mark post 21 that enters in the rear area; a lifting tool (not shown) that can arbitrarily control the lifting distance is set inside the lifting cover 22, and the lifting rod 23 that protrudes below the lifting cover 22 can be raised and lowered; The lower end of the lifting rod 23 is provided with an ultrasonic or high-frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com