Blow molding machine for PE thin film processing

A blow molding machine and film technology, which is applied in the field of blow molding machines for PE film processing, can solve the problems that manual sealing materials are easy to endanger personal safety, and achieve the effect of avoiding endangering workers and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

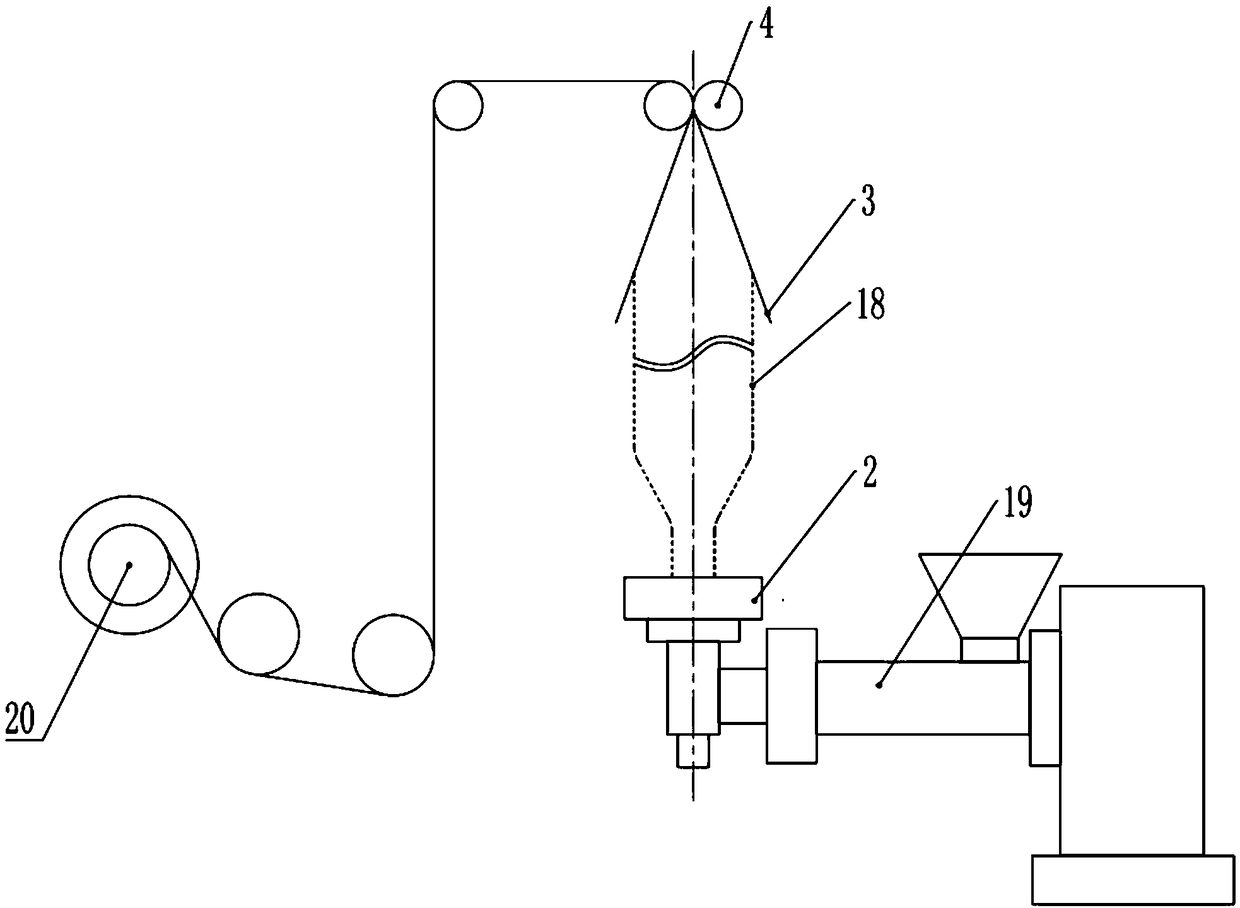

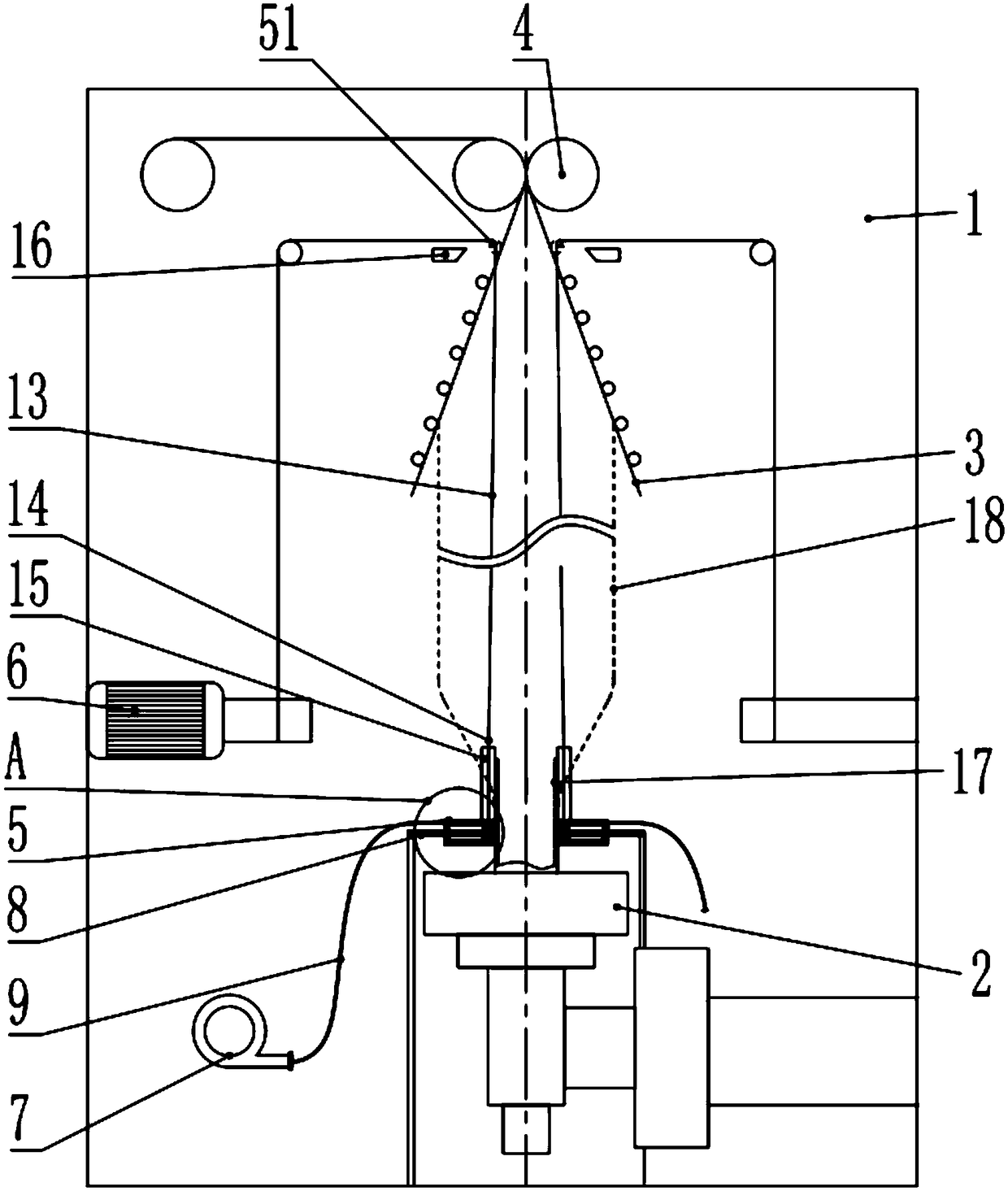

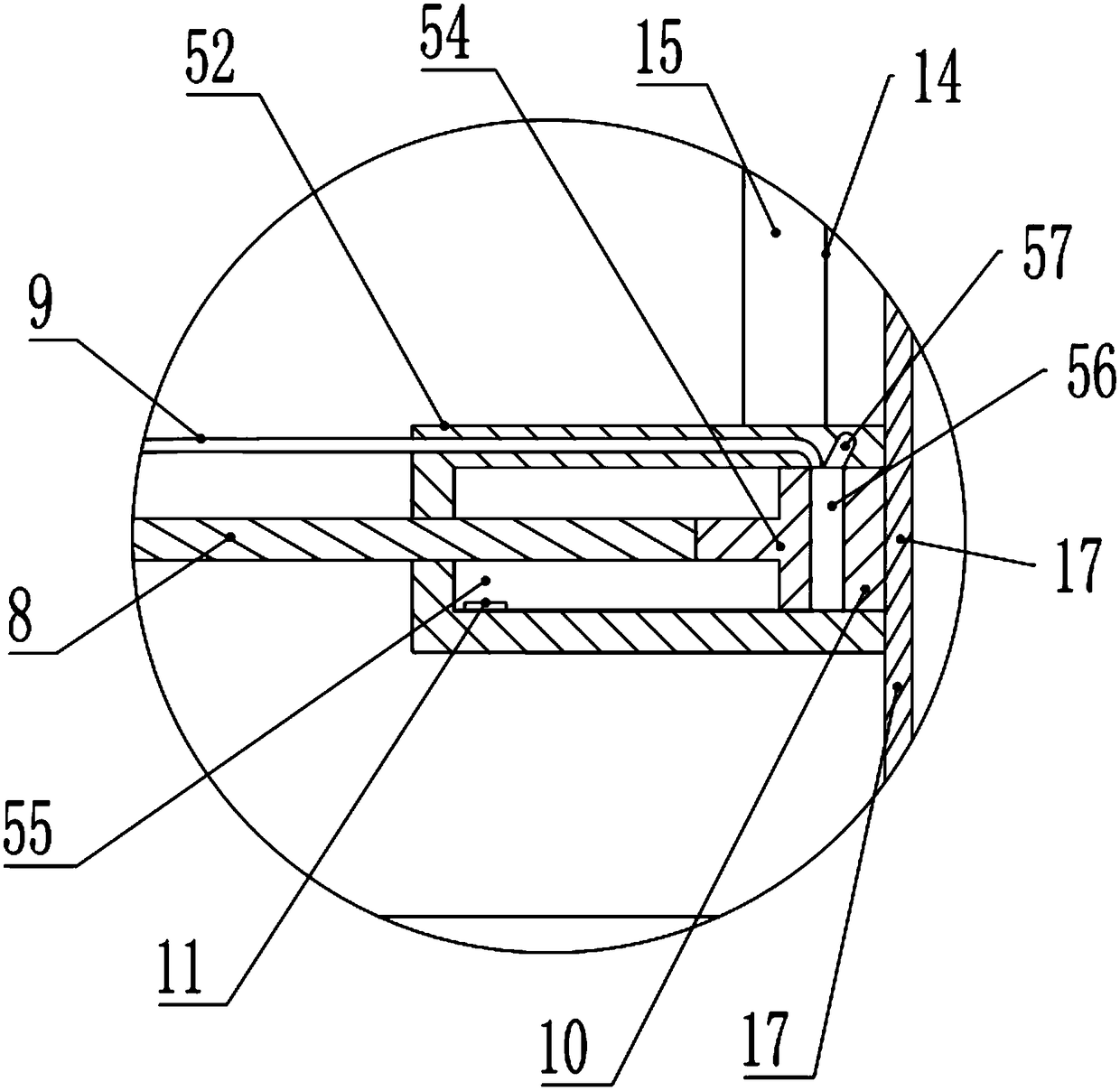

[0036] The following is further described in detail through specific implementation methods:

[0037] The reference signs in the drawings of the description include: frame 1, right-angle machine head 2, herringbone plate 3, traction roller 4, material lifting device 5, motor 6, air pump 7, material lifting roller 51, left material lifting block 52, Right lifting block 53, piston 54, rod cavity 55, rodless cavity 56, piston rod 8, air pipe 9, electromagnet 10, button switch 11, iron block 12, traction steel rope 13, connecting steel rope 14, dry ice 15 , Blowing channel 57, blowing hole 58, wedge 16, thin-walled tube 17, film tube 18, extruder 19, winding roller 20.

[0038] The embodiment is basically as Figure 2 to Figure 5 Shown:

[0039] like figure 2 As shown, the blow molding machine for PE film processing includes a frame 1, a right-angle head 2, a herringbone plate 3, a traction roller 4, a material lifting device 5, a motor 6 and an air pump 7.

[0040] like Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com