Resin composition and prepreg using same, and circuit material

A technology of resin composition and terpene resin, applied in printed circuit, electronic equipment, printed circuit, etc., can solve the problems of insufficient heat resistance, weak intermolecular force, low peel strength, etc., and achieve good film-forming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

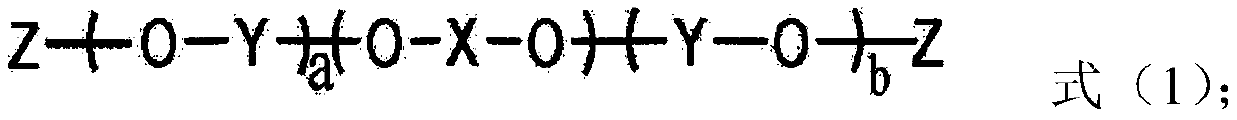

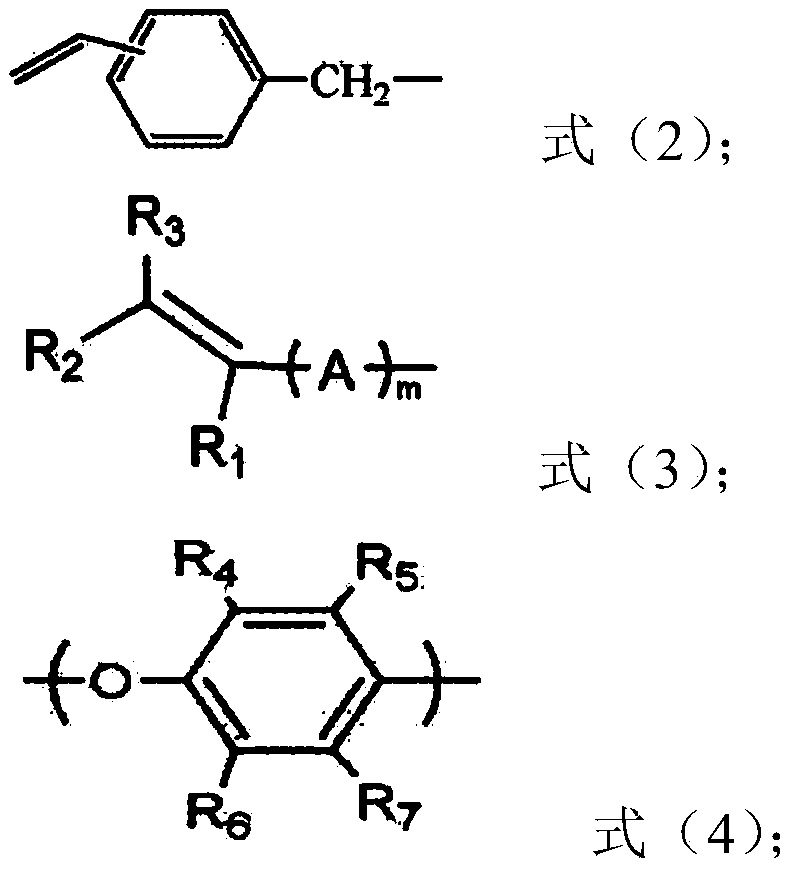

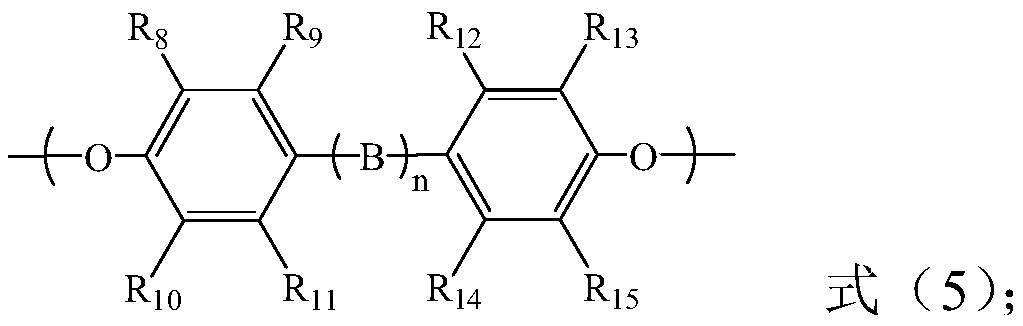

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-6

[0081]Embodiment 1-3 and comparative example 1-6 each provide a kind of circuit material, and its preparation method is as follows:

[0082] Provide prepregs: Synamic6 prepregs, thermosetting hydrocarbon-based substrate materials, self-made by Guangdong Shengyi Technology;

[0083] Preparation of the adhesive layer: dissolve unsaturated polyphenylene ether resin, polyolefin resin, terpene resin, initiator, flame retardant, filler, etc. in xylene according to the proportion, and mix at room temperature to obtain glue; Coating machine coats this glue solution on the copper foil, then bakes in the oven of 155 ℃ for 5 minutes, obtains the copper foil with adhesive layer (adhesive layer unit gram weight is 20g / m 2 ).

[0084] Preparation of circuit materials: 4 pieces of Synamic6 prepregs and copper foil with adhesive layer are stacked neatly (adhesive layer is between the prepreg and copper foil), laminated and cured in a press at 210°C to obtain circuit material.

Embodiment 4

[0086] This embodiment provides a copper clad laminate, the preparation method of which is as follows:

[0087] Dissolve unsaturated polyphenylene ether resin, polyolefin resin, terpene resin, initiator, flame retardant, filler, etc. in xylene in proportion, and mix at room temperature to obtain glue; impregnate the reinforcing material 2116 glass fiber with glue Cloth, dry and semi-cured to obtain a prepreg;

[0088] The above-mentioned prepreg and a piece of copper foil are stacked neatly, laminated and cured in a press at 210° C. to obtain a copper-clad laminate.

Embodiment 5

[0090] This embodiment provides a circuit material, and its preparation method is as follows:

[0091] Provide prepreg: S7136 prepreg, thermosetting hydrocarbon-based substrate material, self-made by Guangdong Shengyi Technology;

[0092] Preparation of the adhesive layer: dissolve unsaturated polyphenylene ether resin, polyolefin resin, terpene resin, initiator, flame retardant, filler, etc. in xylene according to the proportion, and mix at room temperature to obtain glue; The coating machine coats the glue solution on the release film, then bakes it in an oven at 155°C for 5 minutes, removes the release film to obtain an adhesive layer (the unit weight of the adhesive layer is 20g / m 2 );

[0093] Preparation of circuit material: 4 sheets of S7136 prepreg, adhesive layer and copper foil were laminated in sequence, laminated and cured in a press at 210° C. to obtain a circuit material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com