Warp-weft interleave interlayer penetration knitting machine and its weaving method

A method of loom, warp and weft technology, which is applied in the field of penetrating loom between warp and weft interweaving layers and its weaving field, which can solve the problems of enlarged equipment volume, large warp opening, elongated beating-up distance of steel buckles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

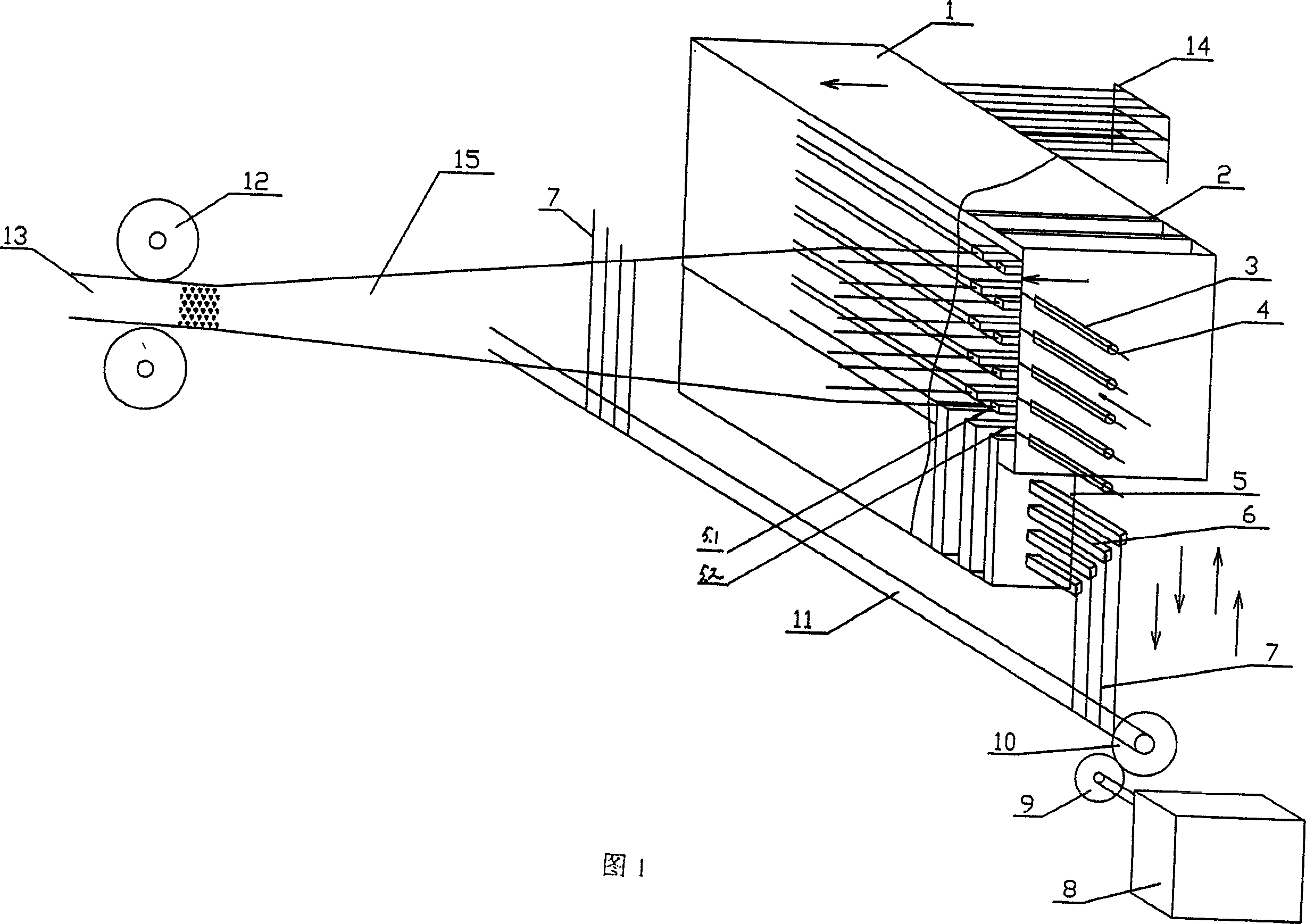

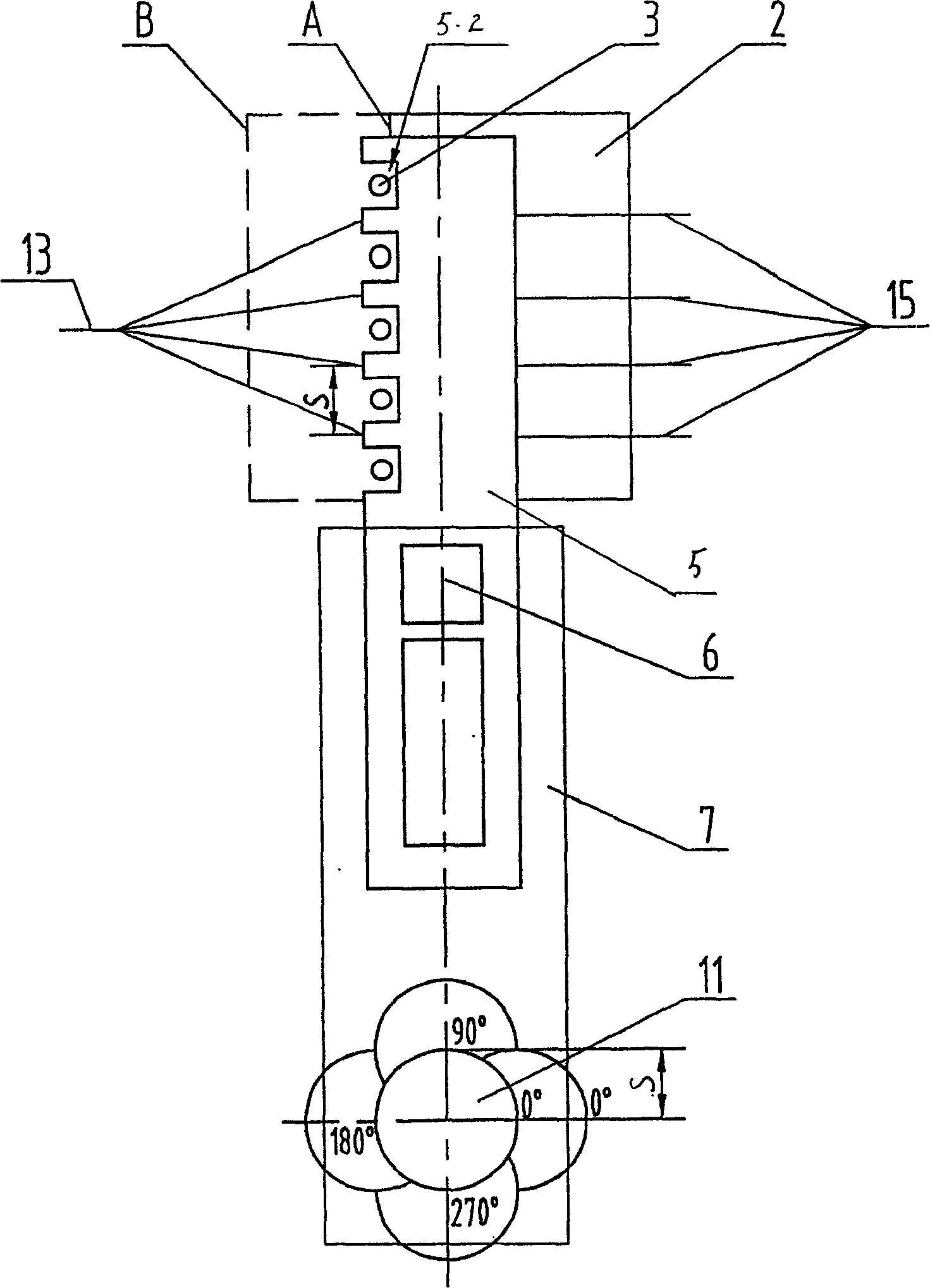

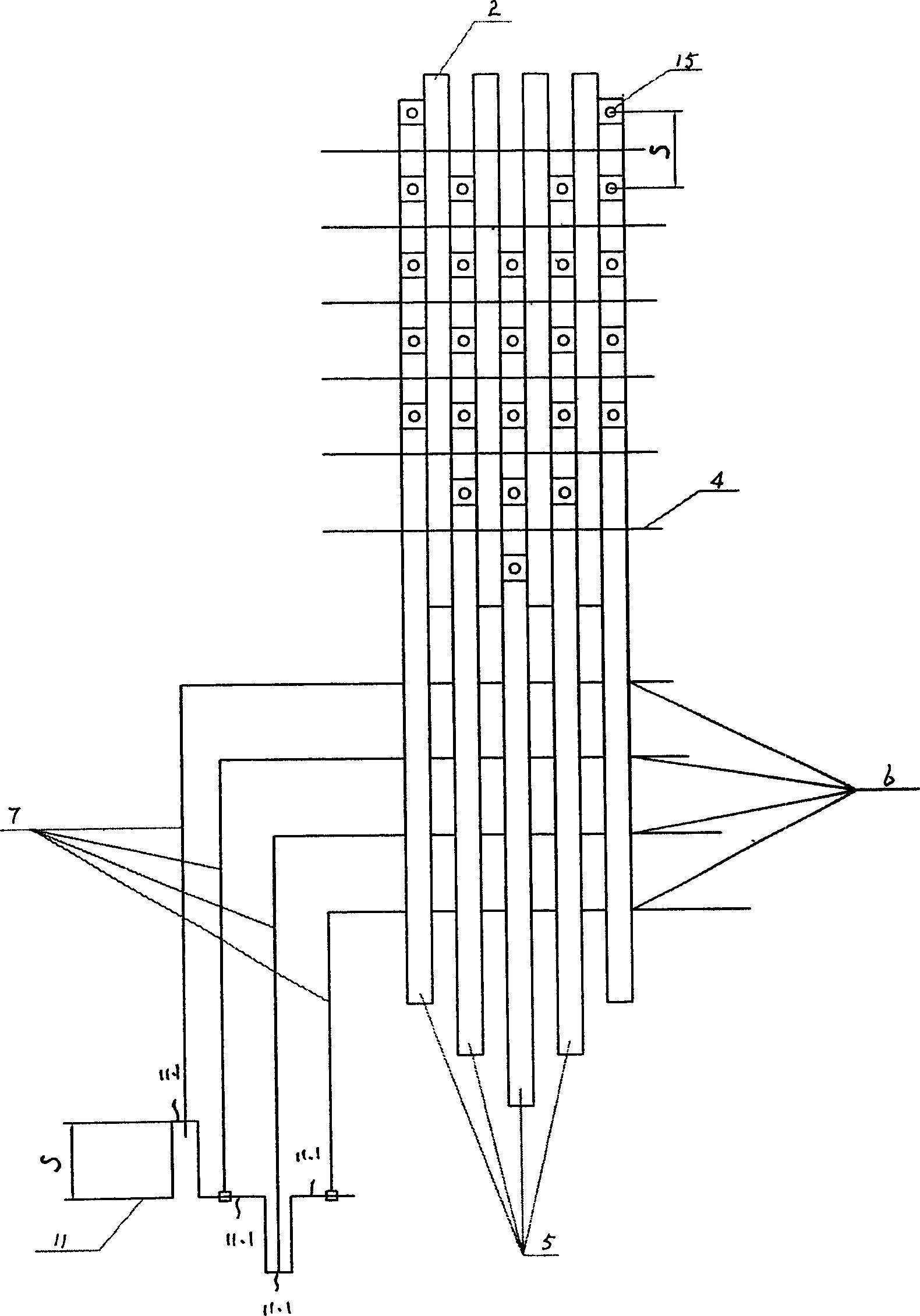

[0027] Refer to Figures 1 to 3, Figures 1 to 3 are interlayer penetration looms of the present invention. In the figure: steel buckle frame 1, steel buckle piece 2, rapier 3, weft yarn 4, brown piece 5, movement of brown piece The pin 6, the connecting rod 7, the imitation punching device 8, the driving gear 9, the transmission gear 10, the transmission shaft 11, the winding device 12, the fabric 13, the warp frame 14 and the warp yarn 15.

[0028] The steel buckle frame 1 has a box-shaped structure.

[0029] The steel buckle 2 has several pieces, and the several steel buckle pieces are vertically inlaid in the steel buckle frame 1 side by side.

[0030] The said rapier 3 adopts a tubular steel rapier, which can make the weft yarn slide smoothly in the tube, and all the rapiers feed the weft synchronously, so that the weft yarn 4 does not contact the brown sheet during the beating-up.

[0031] The brown sheet 5 has several groups according to the width of the loom, and each group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com