System for producing back sealing strips

A production system and technology of back seals, applied to other household appliances, flat products, household appliances, etc., can solve the problems of low interlayer composite strength, low elongation at break, high elongation at break, etc., and achieve interlayer peel strength Effect of high and low elongation at break, high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

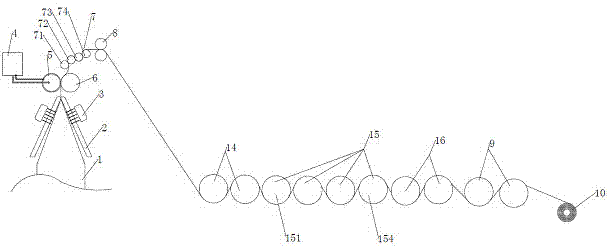

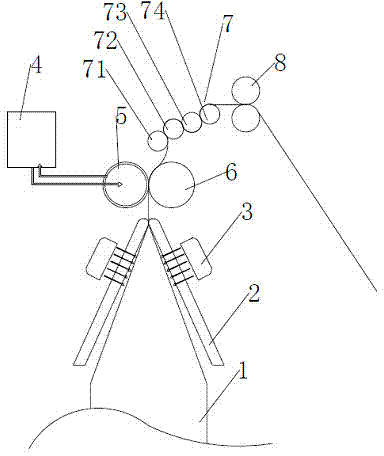

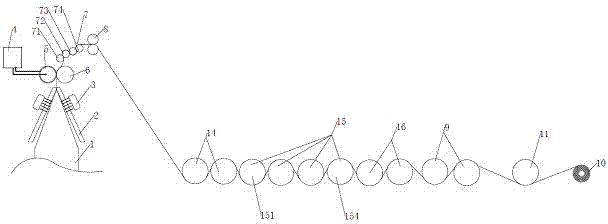

[0029] Such as figure 1 and figure 2 As shown, the present invention is a back seal production system.

[0030] The system includes several extruders (not shown), multi-channel extrusion dies (not shown) with the same number of runners as the number of extruders, herringbone frame 2, traction roller group, heat sealing roller Group 7 , shaping roller group 8 , unidirectional longitudinal stretching mechanism, thickness detection mechanism (not shown), cooling roller group 9 , winding roller 10 .

[0031] Wherein, the herringbone frame 2 is located at the front end of the traction roller group, and is used for crushing the bubble 1 . A far-infrared heating device 3 for preheating the bubble 1 is arranged at the gable 2 . The far-infrared heating device 3 preheats the film bubble 1 to 55-75° C., expands the film bubble, and gradually raises the temperature for preheating. The far-infrared heating device 3 is preferably installed within 1 / 4 to 1 / 3 of the herringbone frame 2 ...

Embodiment 2

[0040] In order to avoid slipping during the stretching process of the longitudinal stretching mechanism, resulting in ineffective stretching, on the basis of Embodiment 1, as an improvement, in this embodiment, the stretching roller 15 of the longitudinal stretching mechanism is set according to the direction of material travel. The first stretching roll 151 and the fourth stretching roll 154 are anilox rolls with 100-200 meshes formed on their surfaces. Otherwise, if slippage is caused, not only is it difficult to stretch and thin evenly, but the harm is that the traction and heat sealing of the front end cannot be carried out effectively, which will lead to frequent shutdowns.

Embodiment 3

[0042] In order to make the performance of the sheet uniform, on the basis of Example 1, as image 3 As shown, a trimming roller 11 for cutting off the edge of the cooled sheet can also be added at the front end of the winding roller 10 .

[0043] In addition, in order to improve the heat-sealing of the film bubble more effectively, on the basis of Example 2, preferably, on both sides of at least one steel roller in the heat-sealing roller group 7, there is a row for forming the edge of the film bubble 1 after being flattened. Air port opening mechanism. Such as Figure 4 As shown, the opening mechanism is provided on both sides of the second steel roller 72 with the teeth 12 having a triangular cross-section. At the same time, the first steel roller 71 and the third steel roller 73 are provided with grooves 13 matching with the notches 12 at positions corresponding to the notches 12 of the second steel roller 72 . Arranging the notched teeth 12 in this way not only realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com