Solar cell back panel film and preparation method thereof

A solar cell and backplane film technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of affecting the service life of the battery, high requirements for coating technology, and easy fall-off of fluoroplastics, etc., to achieve excellent overall performance, No solvent pollution, less production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

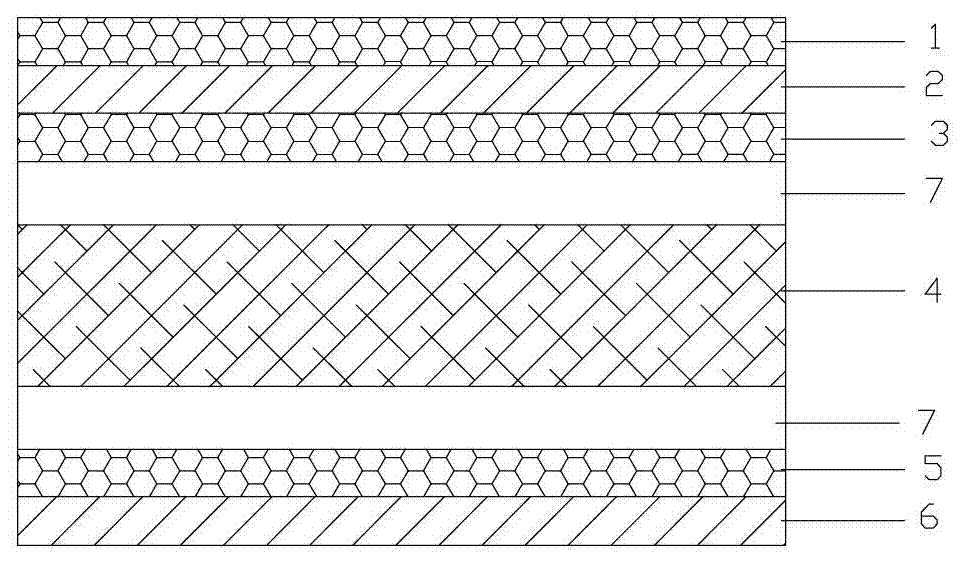

[0026] Embodiment 1, a solar battery backsheet film, from top to bottom is the first transition layer 1, the first weather-resistant layer 2, the second transition layer 3, the substrate 4, the third transition layer 5 and the second weather-resistant layer 6 , the substrate 4 is bonded with the second transition layer 3 and the third transition layer 5 through an adhesive layer 7; the first transition layer, the first weather-resistant layer and the second transition layer are cast by three layers of co-extrusion The three-layer composite film layer prepared by the method, the thickness of the three-layer composite film is 25 μm, wherein the thickness of the first transition layer, the first weather-resistant layer and the second transition layer are equal; the third transition layer 5 and the second weather-resistant layer 6 are made by The double-layer composite film is prepared by double-layer co-extrusion casting, and the thickness of the double-layer composite film is 20 ...

Embodiment 2-4

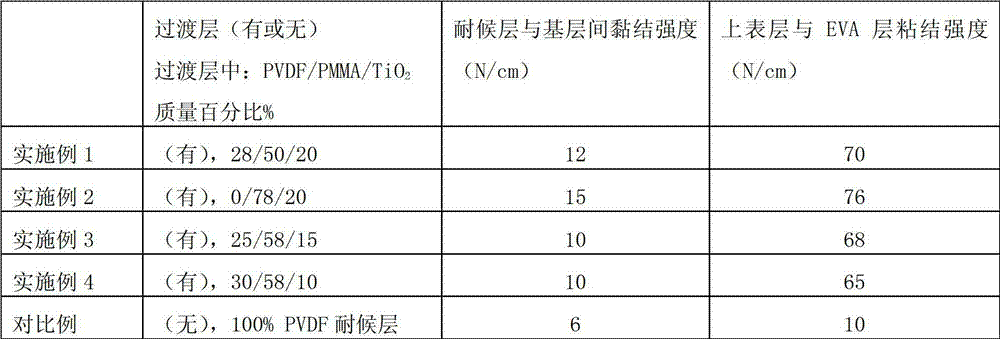

[0038] As described in Example 1, the difference is that polymethyl methacrylate (PMMA), polyvinylidene fluoride (PVDF), titanium dioxide (TiO 2 ) content are 78%, 0, 20%; 58%, 25%, 15%; 58%, 30%, 10%. The bond strength test results of the obtained products are listed in Table 1.

Embodiment 5

[0043] Embodiment 5, as described in Embodiment 1, the difference is:

[0044] The transition layer is polyvinylidene fluoride (PVDF) 30% and polymethyl methacrylate (PMMA) 50%, inorganic filler TiO 2 Nano powder 20% mixture. The polyester base layer 3 is polybutylene terephthalate (PBT) with a thickness of 150 μm. The weather-resistant layer is polyvinylidene fluoride (PVDF). The bonding strength between the upper surface layer (the first transition layer) and the EVA layer of the obtained product is 69N / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com