PETG/PET co-extrusion self-heat-sealing multilayer film and preparation method thereof

A technology of multi-layer film and heat-sealing layer, applied in the direction of chemical instruments and methods, flat products, layered products, etc., can solve many problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

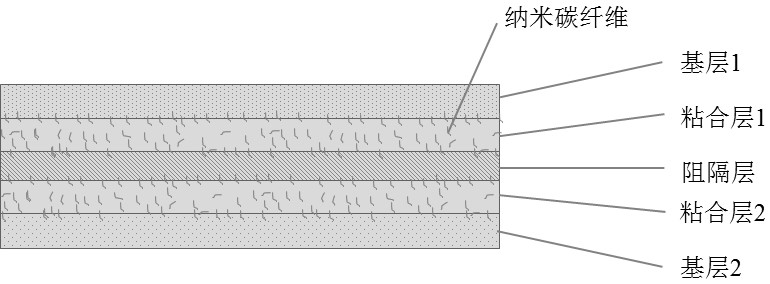

Image

Examples

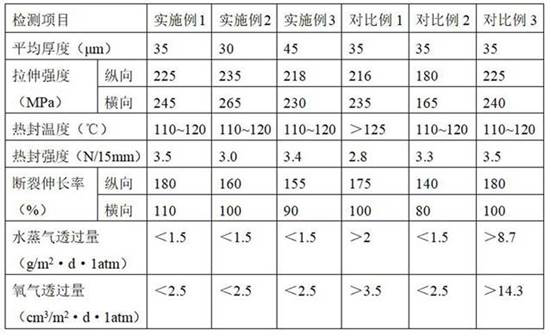

Embodiment 1

[0040] (1) PET (FG620, Sinopec Yizheng Chemical Fiber), PETG (SKYGREEN® S2008), PA (MXD6), etc. are dried and dehumidified before being melt extruded for use:

[0041] (2) After mixing the raw materials of each layer of the PETG / PET co-extruded self-heat-sealing multi-layer film according to the proportions, they are sent to different extruders for melting and plasticizing, wherein:

[0042] Base layer 1 was prepared from the following raw materials by mass percentage: 16% metallocene PE (5100G, Dow) and 84% PETG (SKYGREEN® S2008);

[0043] Base layer 2 is prepared from the following raw materials by mass percentage: 99.89% PET (FG620, Sinopec Yizheng Chemical Fiber), 0.1% anti-blocking agent silicon dioxide powder and 0.01% slip agent crodamide ER;

[0044] Adhesive layer 1 and adhesive layer 2 are prepared from the following raw materials by mass percentage: 68% maleic anhydride grafted polypropylene (ADMER SE800), 25% PETG (SKYGREEN® S2008) and 7% nano-carbon fibers;

[00...

Embodiment 2

[0051] (1) PET (FG620, Sinopec Yizheng Chemical Fiber), PETG (SKYGREEN® S2008), PA (MXD6), etc. are dried and dehumidified before being melt extruded for use:

[0052] (2) After mixing the raw materials of each layer of the PETG / PET co-extruded self-heat-sealing multi-layer film according to the proportions, they are sent to different extruders for melting and plasticizing, wherein:

[0053] The base layer 1 was prepared from the following raw materials by mass percentage: 10% metallocene PE (5100G, Dow) and 90% PETG (SKYGREEN® S2008);

[0054] Base layer 2 is prepared from the following raw materials by mass percentage: 99.85% PET (FG620, Sinopec Yizheng Chemical Fiber), 0.1% anti-blocking agent silicon dioxide powder and 0.05% slip agent crodamide ER;

[0055] Adhesive layer 1 and adhesive layer 2 are prepared from the following raw materials by mass percentage: 60% maleic anhydride grafted polypropylene (ADMER SE800), 30% PETG (SKYGREEN® S2008) and 10% nano carbon fiber;

...

Embodiment 3

[0062] (1) PET (FG620, Sinopec Yizheng Chemical Fiber), PETG (SKYGREEN® S2008), PA (MXD6), etc. are dried and dehumidified before being melt extruded for use:

[0063] (2) After mixing the raw materials of each layer of the PETG / PET co-extruded self-heat-sealing multi-layer film according to the proportions, they are sent to different extruders for melting and plasticizing, wherein:

[0064] The base layer 1 was prepared from the following raw materials by mass percentage: 20% metallocene PE (5100G, Dow) and 80% PETG (SKYGREEN® S2008);

[0065] The base layer 2 is prepared from the following raw materials by mass percentage: 99.75% PET (FG620, Sinopec Yizheng Chemical Fiber), 0.2% anti-blocking agent silicon dioxide powder and 0.05% slip agent crodamide ER;

[0066] Adhesive layer 1 and adhesive layer 2 are prepared from the following raw materials by mass percentage: 70% maleic anhydride grafted polypropylene (ADMER SE800), 25% PETG (SKYGREEN® S2008) and 5% nano carbon fiber;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com