Polyurethane binder as well as preparation method and application thereof

An adhesive, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of shrinkage of the back panel, easy yellowing of solvent-free adhesive, brittle adhesive layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

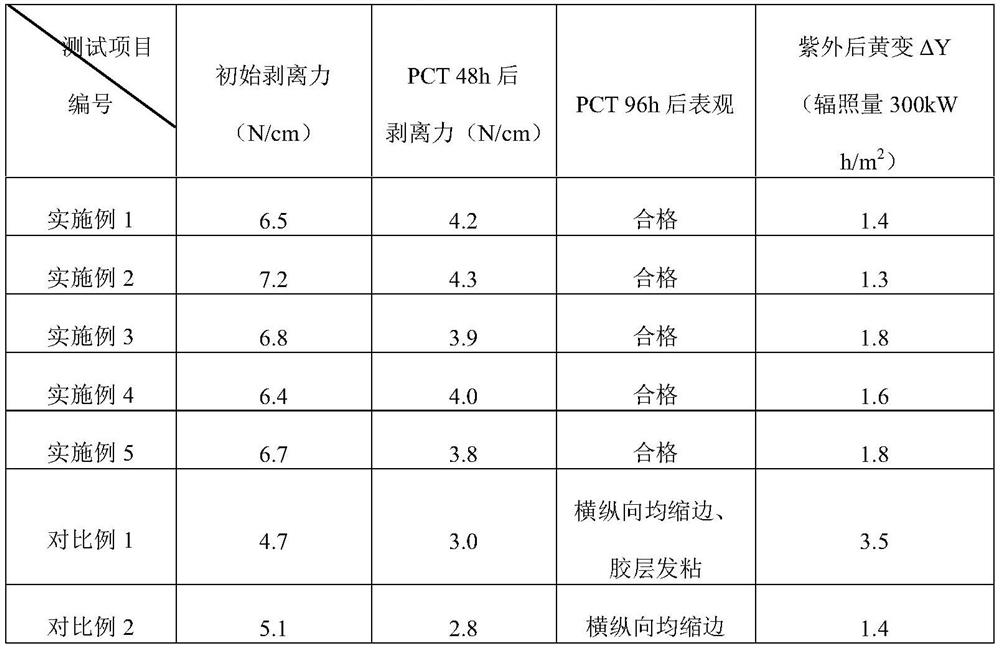

Examples

Embodiment 1

[0052] Take by weighing 5g methyl methacrylate monomer, 65g ethyl acrylate, 20g-2-hydroxyethyl methacrylate, 10g butyl acrylate, add solvent 50g ethyl acetate solvent, 2g initiator azobisisobutyronitrile, 1g of lauryl mercaptan was reacted at 70°C for 2 hours to obtain a polyacrylate polyol resin solution, and then vacuumed to remove the solvent to obtain a polyacrylate polyol resin with a hydroxyl value of 97mg / gKOH and a molecular weight of 1100.

[0053] Take by weighing the above-mentioned polyacrylate polyol of 80g, the polypropylene glycol N-220 (Jiangsu Zhongshan Chemical Industry Co., Ltd.) that 10g molecular weight is 2000, the polyoxypropylene triol MN-1500 (Japan Mitsui Co., Ltd.) that 10g molecular weight is 1500, After adding the antioxidant tetra-β (3,5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol propionate (the amount added accounts for 0.5% of the total weight of the polyurethane binder), vacuum dehydration at 110°C , the molar ratio of the hydroxyl group in...

Embodiment 2

[0056] Weigh 8g ethyl methacrylate monomer, 70g butyl acrylate, 15g-4-hydroxybutyl methacrylate, 10g methyl acrylate, add solvent 50g ethyl acetate solvent, 1.8g initiator azobisisobutyronitrile , 0.8g lauryl mercaptan, reacted at 70°C for 2h to obtain a polyacrylate polyol resin solution, and then vacuumed out the solvent to obtain a polyacrylate polyol resin with a hydroxyl value of 59mg / gKOH and a molecular weight of 1900.

[0057] Take by weighing the above-mentioned polypropylene ester polyol of 65g, 32g molecular weight is the polyether diol DL-1000 (Shandong Dongda Blue Star Chemical Industry) of 1000, 3g molecular weight is the polyoxypropylene triol Poly-G-30-240 of 700 ( U.S. Arch Chemical Company), after adding antioxidant 3, 5-di-tert-butyl-4-hydroxyphenyl propionate octadecyl alcohol ester (addition accounts for 0.3% of the total weight of the polyurethane binder), after Under vacuum dehydration at 110°C, the molar ratio of the hydroxyl group in the polyol to the ...

Embodiment 3

[0060] Weigh 5g methyl methacrylate, 65g butyl acrylate, 15g-2-hydroxyethyl acrylate, 8g ethyl acrylate, 7g ethyl methacrylate, add solvent 50g ethyl acetate solvent, 2g initiator azobisiso Butyronitrile and 0.8g lauryl mercaptan were reacted at 70°C for 2 hours to obtain a polyacrylate polyol resin solution, and then vacuumed to remove the solvent to obtain a polyacrylate polyol resin with a hydroxyl value of 72mg / gKOH and a molecular weight of 1500.

[0061]Take by weighing the above-mentioned polyacrylate polyol resin of 75g, the polyether glycol PPG600 (Jiangsu Zhongshan Chemical Co., Ltd.) that 20g molecular weight is 600, the polyoxypropylene triol MH-1000 (Japan Mitsui Co., Ltd.) that 5g molecular weight is 1500 ), adding antioxidant N, N-bisβ[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl] hexamethylenediamine (addition accounts for 0.4% of the total weight of polyurethane binder ), after vacuum dehydration at 110°C, the molar ratio of the hydroxyl group in the polyol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com