Loom with functions of warp-weft plain-weaving and z-directional yarn interweaving and weaving method thereof

A technology of weaving, warp and weft, applied in the directions of looms, textiles, papermaking, fabrics, etc., can solve the problems of large warp weaving angle, fiber hair, and large equipment volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

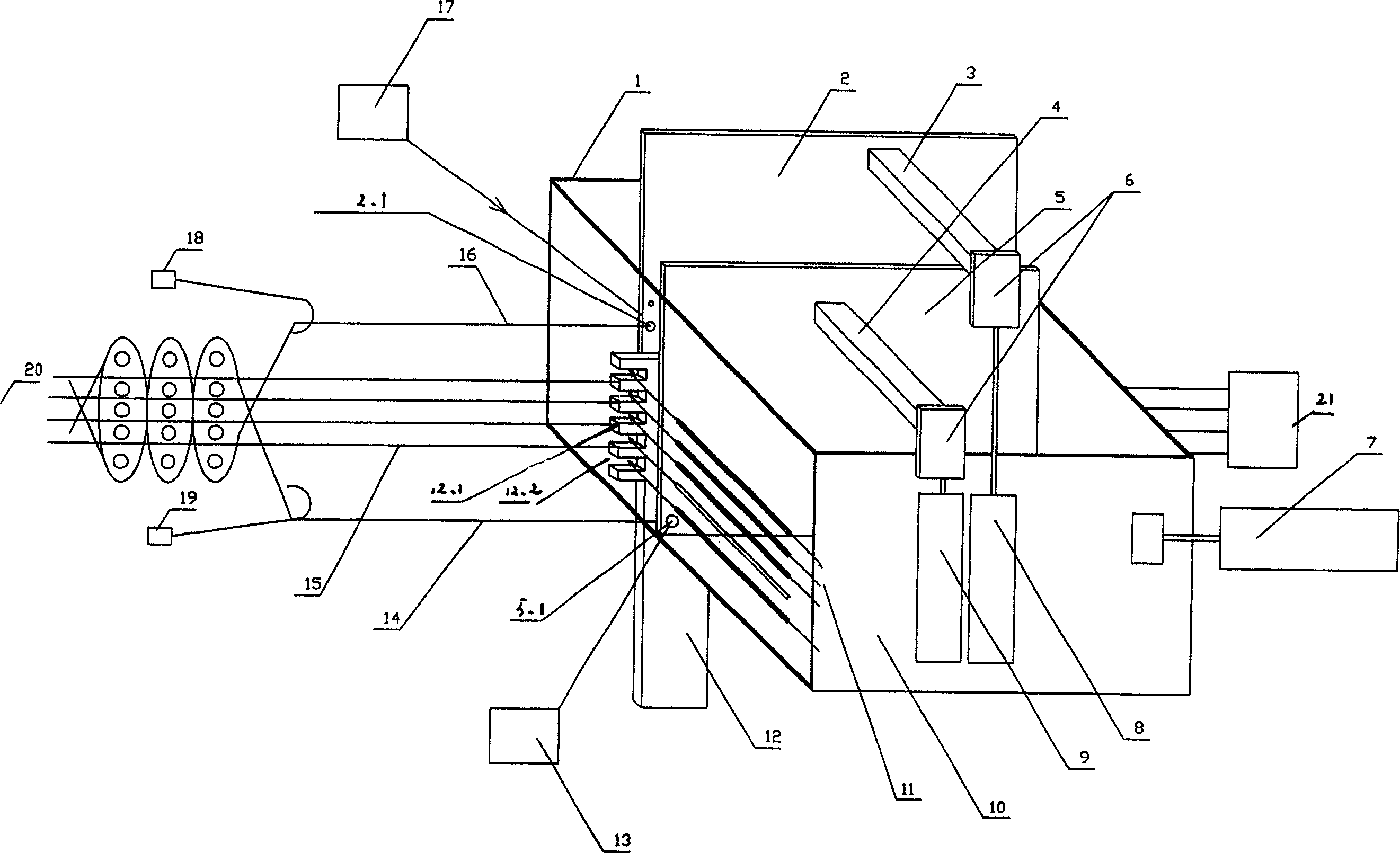

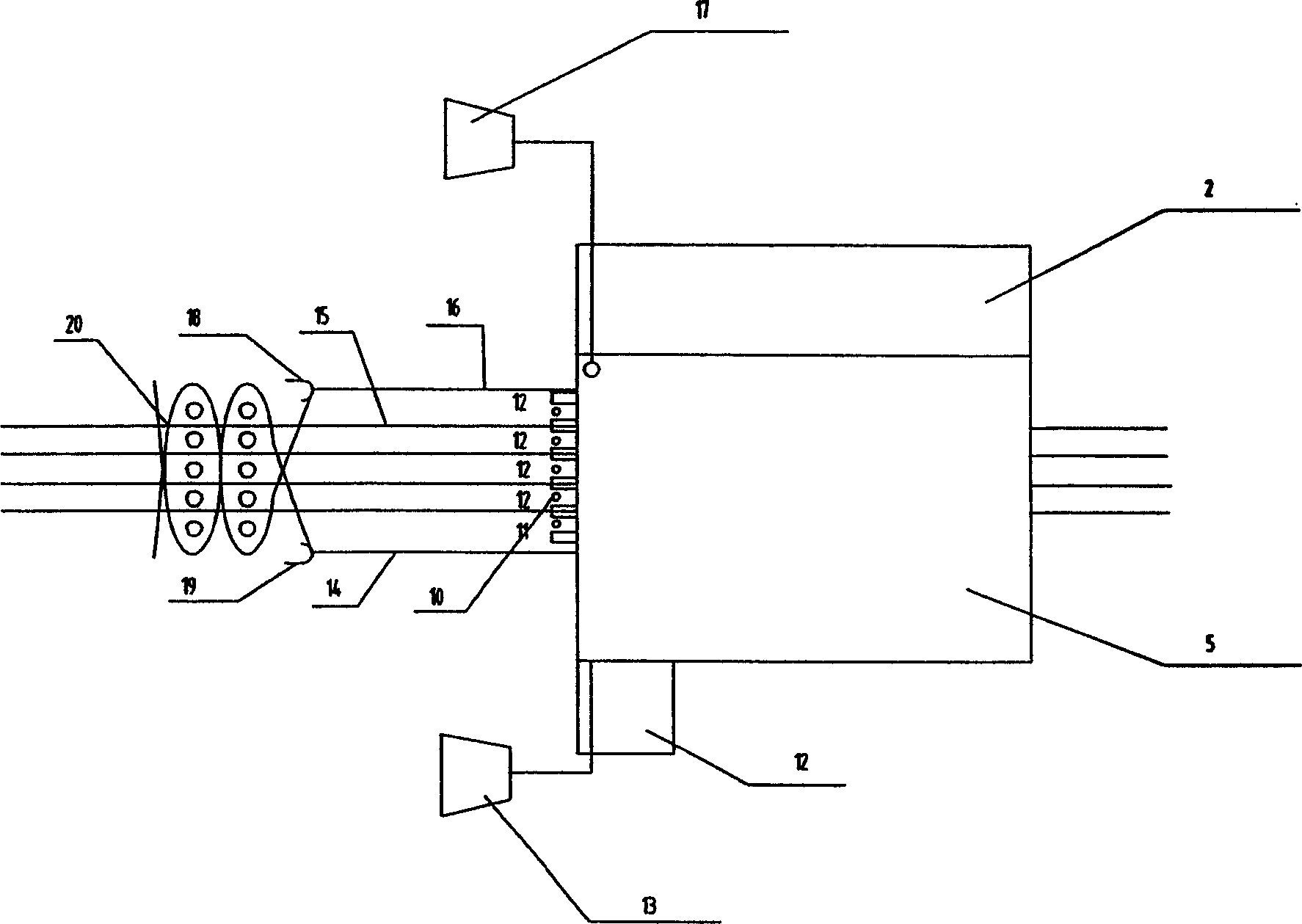

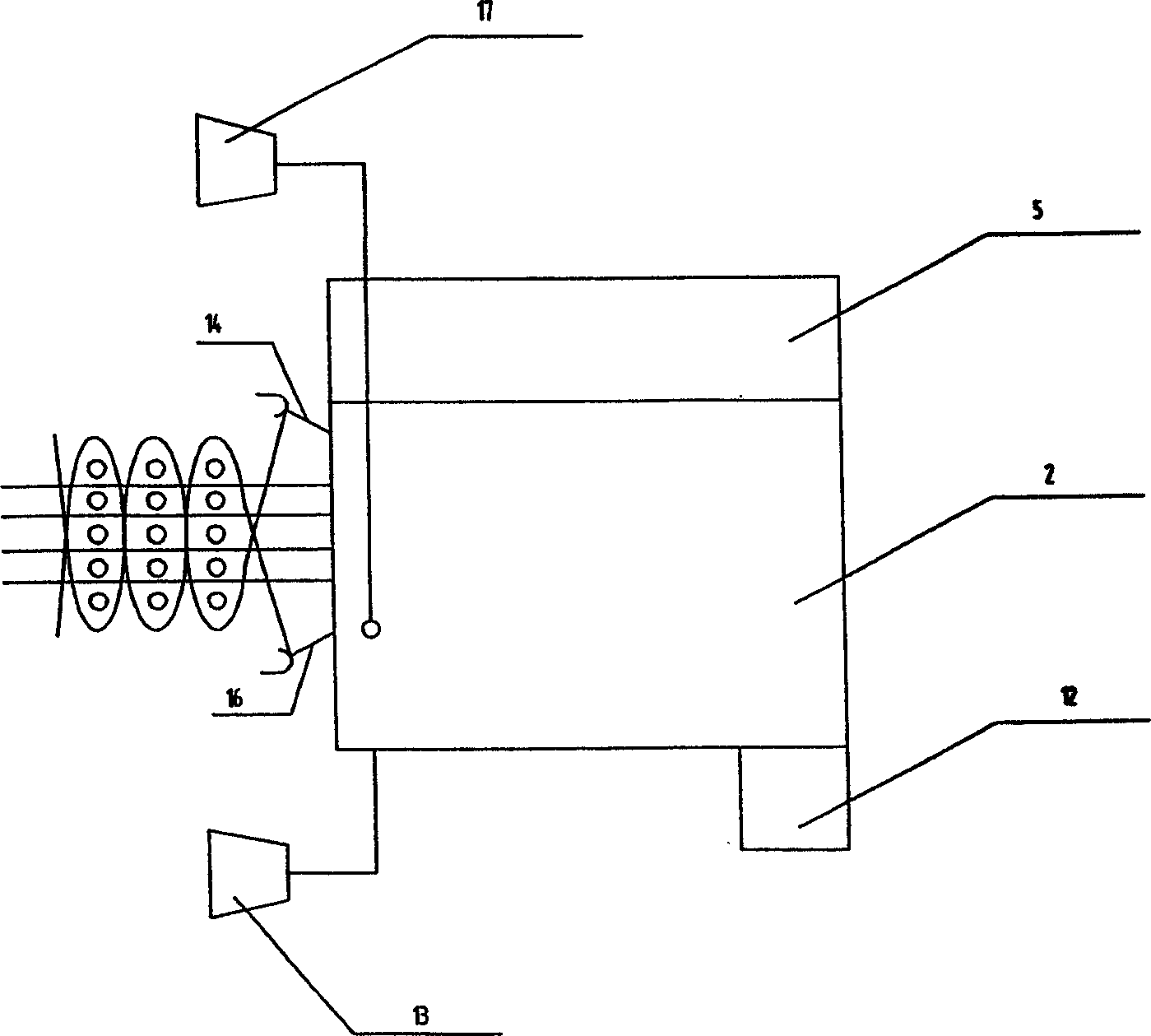

[0026] see figure 1 , figure 1 It is a flat weave loom with warp and weft interlaced and Z-direction yarns interlaced. In the figure: steel button frame 1, steel button piece 2, steel button piece moving tip 3, steel button piece moving tip 4, steel button piece 5, connecting rod 6, , Steel buckle motion cylinder 8, steel buckle motion cylinder 9, weft yarn 10, rapier 11, brown piece 12, Z 1 Yarn storage device 13, Z 1 Yarn 14, Warp 15, Z 2 Yarn 16, Z 2 Yarn yarn storage device 17, upper and lower yarn hook 18, upper and lower yarn hook 19, fabric 20, warp yarn frame 21 and winding device (not shown in the figure) form.

[0027] Described steel buckle frame 1 links to each other with beating-up cylinder 7, and beating-up cylinder 7 is longitudinally fixed on the frame;

[0028] The steel buckles 2 and 5 have several pieces, and the steel buckles are divided into two rows in the steel buckle frame 1, and the upper and lower staggered intervals are arranged, and the ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com