Adhesive for protective film on the back of a solar cell and application thereof

A backside protective film, solar cell technology, applied in the direction of film/sheet adhesives, adhesives, adhesive types, etc., can solve the problems of high adhesive viscosity, difficult processing and construction, etc., to achieve hydrolysis resistance The effect of lifting, high peel strength between layers, and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

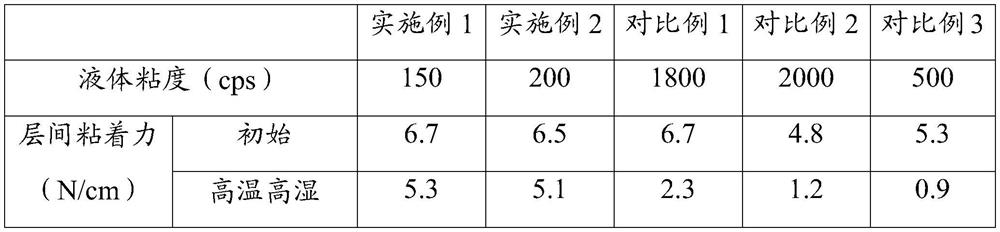

Examples

Embodiment 1

[0030] The adhesive for the protective film on the back of the solar cell comprises the following components by weight: 100 parts of polyester resin and 20 parts of melamine formaldehyde resin.

[0031] The preparation method of the melamine formaldehyde resin is as follows: add melamine to the formaldehyde aqueous solution with a pH value of 8-8.5, heat up to 70°C and keep it warm, and continue the heat preservation reaction for half an hour after the system is clarified, then cool down to 40°C, and add methanol , and then adjust the pH value to 5-6, raise the temperature to 50° C. for 1 hour, and adjust the pH value to 8-9 again to obtain the desired melamine formaldehyde resin. The molar ratio of the melamine to formaldehyde is 1:3, and the molar ratio of the melamine to methanol is 1:15.

[0032] Wherein the polyester resin is a polycarboxylic acid and a polyhydric alcohol copolymer, and the polycarboxylic acid contains 60mol% of a mixture of phthalic acid, terephthalic ac...

Embodiment 2

[0036] The adhesive for the protective film on the back of the solar cell comprises the following components by weight: 100 parts of polyester resin and 20 parts of melamine formaldehyde resin.

[0037] The preparation method of the melamine formaldehyde resin is as follows: add melamine to the formaldehyde aqueous solution with a pH value of 8-8.5, heat up to 70°C and keep it warm, and continue the heat preservation reaction for half an hour after the system is clarified, then cool down to 40°C, and add methanol , and then adjust the pH value to 5-6, raise the temperature to 50° C. for 1 hour, and adjust the pH value to 8-9 again to obtain the desired melamine formaldehyde resin. The molar ratio of the melamine to formaldehyde is 1:6, and the molar ratio of the melamine to methanol is 1:20.

[0038] Wherein the polyester resin is a polycarboxylic acid and a polyhydric alcohol copolymer, and the polycarboxylic acid contains 90 mol% of a mixture of phthalic acid, terephthalic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com