Adhesive for aluminum battery packaging aluminum plastic film, aluminum plastic film and preparation method of aluminum plastic film

A technology of aluminum-plastic film and lithium battery, applied in the direction of adhesives, adhesive types, chemical instruments and methods, etc., can solve problems such as poor electrolyte resistance, weak adhesion, delamination of aluminum-plastic films, etc., to achieve adhesion Improved performance, high adhesion, good resistance to solvents and acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

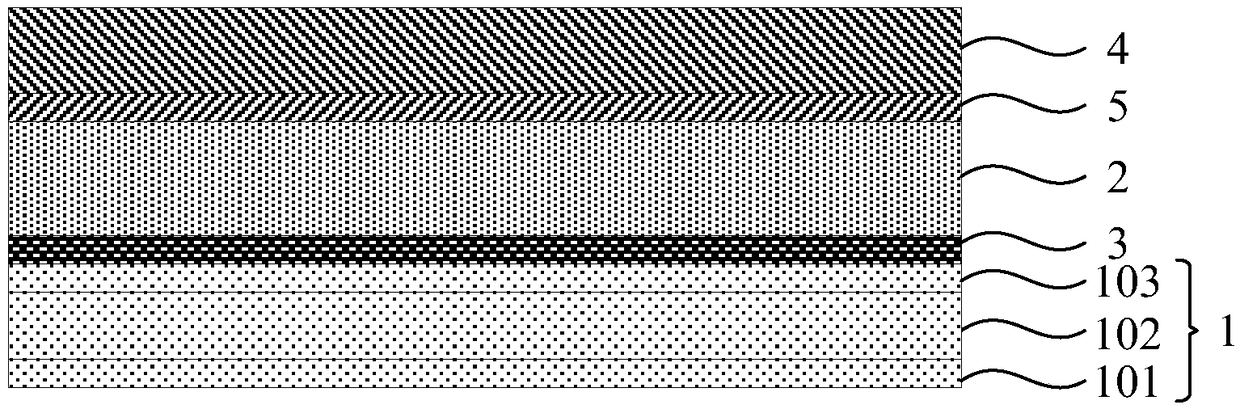

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing an adhesive for lithium battery packaging aluminum-plastic film in the above scheme, the preparation method at least comprising:

[0050]adding the main resin into the first solvent, heating, adding the tackifying resin, the anti-hydrolysis agent, the second solvent and the curing agent in sequence after stirring, and then filtering to remove the insoluble matter to obtain the obtained Adhesives mentioned above.

[0051] As an example, the total solid content of the adhesive is between 10% and 20%.

[0052] As an example, the first solvent includes a mixture of cyclohexane and butanone, and the second solvent includes a mixture of cyclohexane and butanone.

[0053] As an example, in the first solvent, the mass ratio of the cyclohexane to the butanone is between 7:1 and 9:1; in the second solvent, the cyclohexane and the butanone The mass ratio of butanone is between 1:2 and 1:4.

[0054] The present invention...

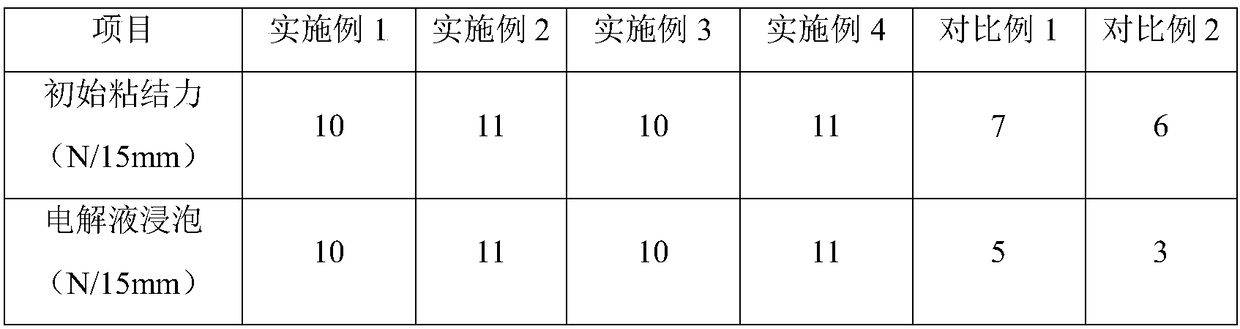

Embodiment 1

[0067] 1. The high-adhesion adhesive for lithium battery packaging aluminum-plastic film of the present embodiment includes at least the following components in mass percentage: 10% main resin, 1.5% curing agent, 0.5% tackifying resin, 0.2% anti-hydrolysis agent , 87.8% mixed solvent, wherein the mixed solvent is 58.8% cyclohexane, 29% butanone.

[0068] 2. The preparation method of the high-adhesion adhesive for lithium battery packaging aluminum-plastic film of this embodiment includes: first adding the main resin to the mixed solvent, heating at 40 ° C for 24 hours, and then adding the corresponding amount of Tackifying resin, anti-hydrolysis agent, mixed solvent (cyclohexane, methyl ethyl ketone) and curing agent, the total solid content of the adhesive is about 10%, and the PP filter element is used for filtration to remove insoluble matter, that is, for coating.

[0069] 3. The preparation method of the lithium battery packaging aluminum-plastic film of the present embod...

Embodiment 2

[0071] 1. The high-adhesion adhesive for lithium battery packaging aluminum-plastic film of the present embodiment includes at least the following components in mass percentage: 12% main resin, 1.5% curing agent, 0.8% tackifying resin, 0.2% anti-hydrolysis agent , 85.5% mixed solvent, wherein the mixed solvent is 58.5% cyclohexane, 27% butanone.

[0072] 2. The preparation method of the high-adhesion adhesive for lithium battery packaging aluminum-plastic film in this embodiment includes: first adding the main resin into the mixed solvent, heating at 40°C for 24 hours, and then adding the corresponding amount of Tackifying resin, anti-hydrolysis agent, mixed solvent (cyclohexane, methyl ethyl ketone) and curing agent, the total solid content of the adhesive is about 12%, filter with a PP filter element to remove insoluble matter, that is, to use for coating

[0073] 3. The preparation method of the aluminum-plastic film for lithium battery packaging in this embodiment includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com