Isotropic high-performance thermal conductive adhesive for filling carbon nano tube

An isotropic, carbon nanotube technology, applied in the direction of adhesives, other rubber adhesives, non-polymer adhesive additives, etc., can solve the problems of low bonding strength and low thermal conductivity of thermally conductive adhesives, and achieve bonding High strength, high thermal conductivity, easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Weigh epoxy resin, epoxy toughness modifier, adhesion promoter, rheology control agent according to the mass given in Table 2 and mix them. The way of mixing is mechanical stirring, the stirring rate is 1000 rpm, and the time is 10 minutes. Then add the weighed heat-conducting filler, filler surface modifier, and diluent to the mixture in a stirring state. Stirring was continued for 10 minutes after the addition was complete. After mixing evenly, add curing agent and curing accelerator to the mixture, mechanically stir for 5 minutes, transfer the mixture to a high-speed shear mixer for mixing, the mixing speed is 2000 rpm, and the time is 30s. Repeat the mixing process in the high-speed shear mixer three times to obtain a uniformly mixed jelly, which is the thermally conductive adhesive.

[0033] The preparation of the test sample for the bonding strength of the thermal conductive adhesive is carried out in accordance with the standard ASTM1002-01. First...

Embodiment 2~11

[0038]According to the composition and dosage listed in Table 2, weigh epoxy resin, epoxy toughness modifier, adhesion promoter, rheology control agent and mix them. The way of mixing is mechanical stirring, the stirring rate is 1000 rpm, and the time is 10 minutes. Then add the weighed heat-conducting filler, filler surface modifier, and diluent to the mixture in a stirring state. Stirring was continued for 10 minutes after the addition was complete. After mixing evenly, add curing agent and curing accelerator to the mixture, mechanically stir for 5 minutes, transfer the mixture to a high-speed shear mixer for mixing, the mixing speed is 2000 rpm, and the time is 30s. Repeat the mixing process in the high-speed shear mixer three times to obtain a uniformly mixed jelly, which is the thermally conductive adhesive.

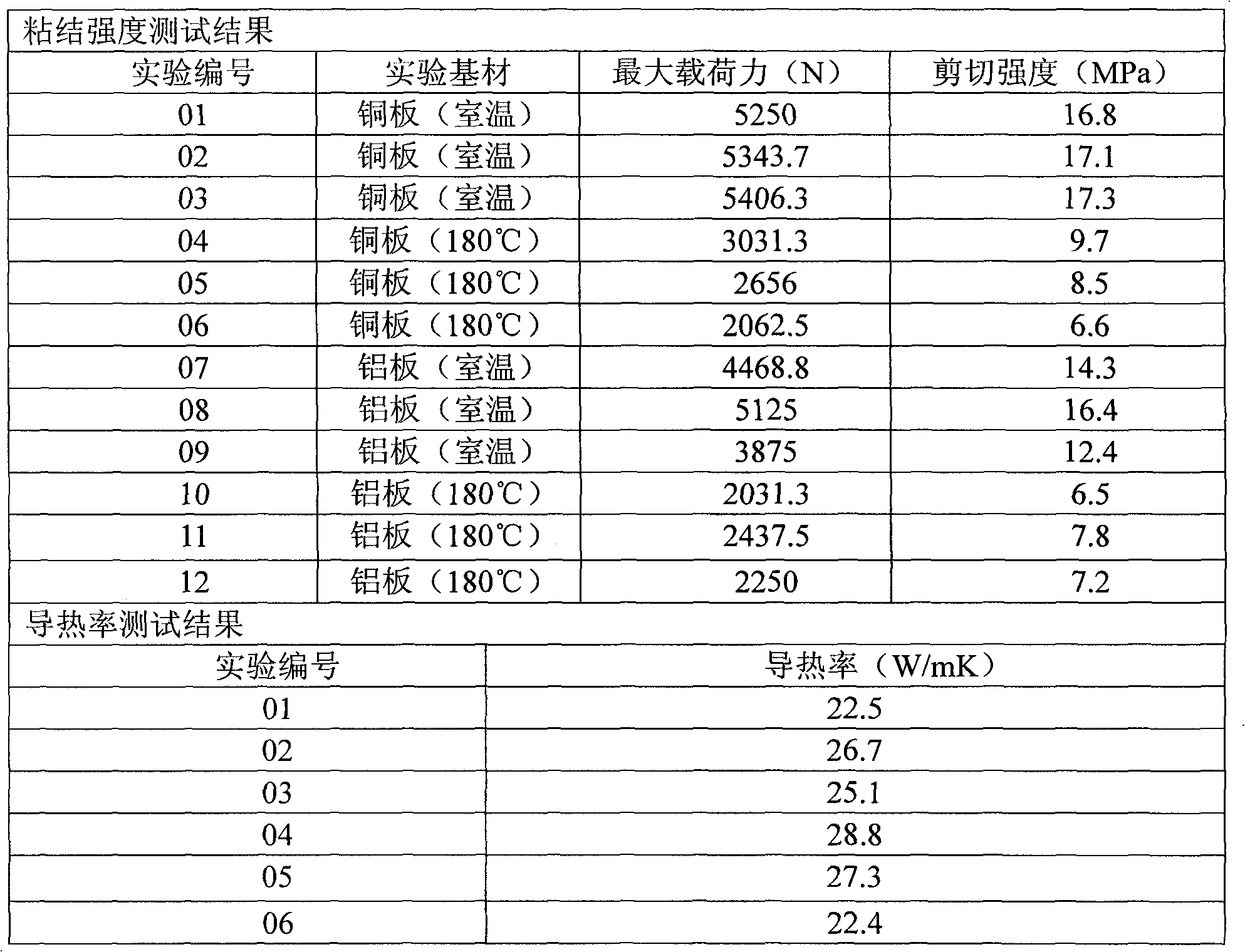

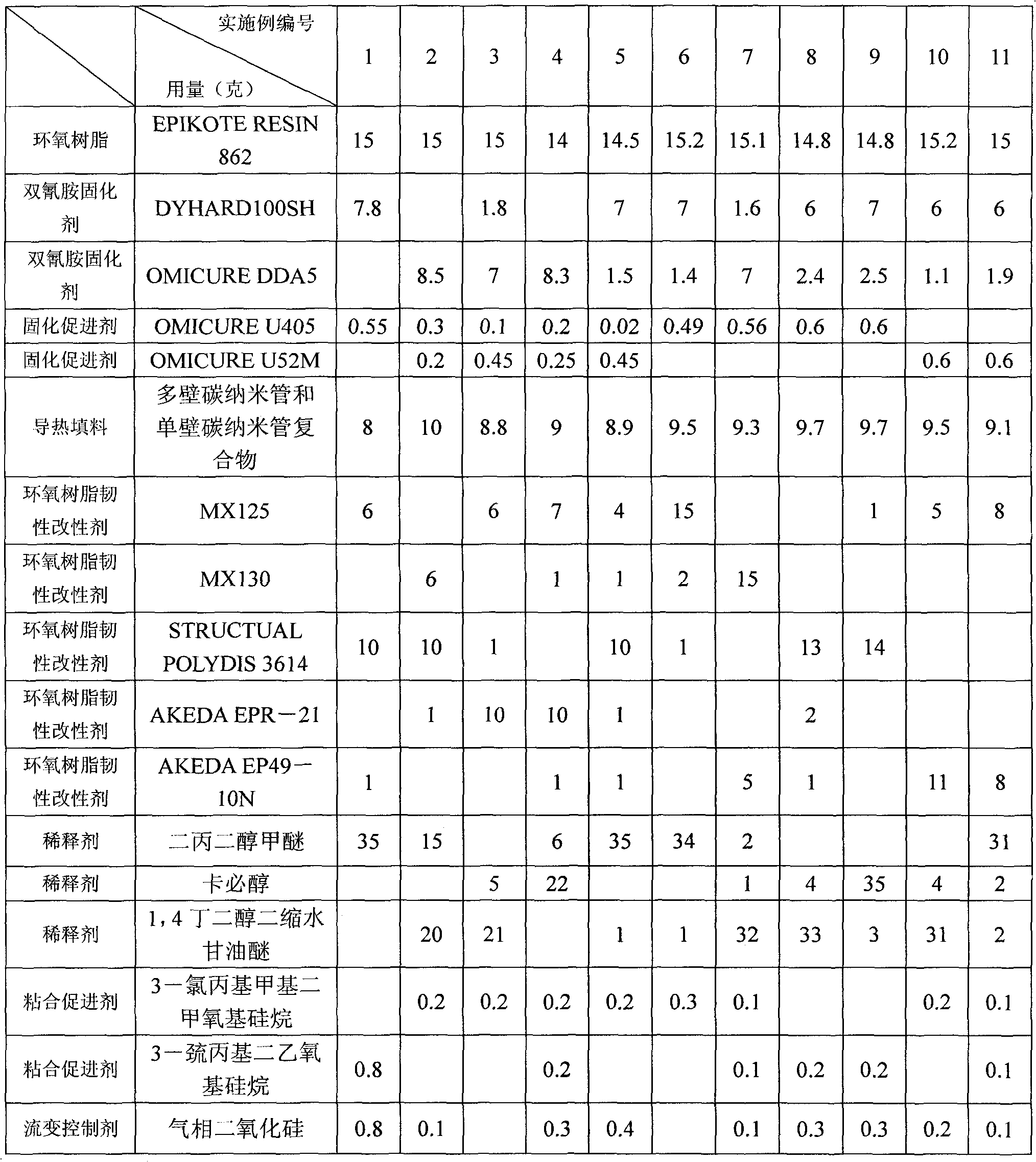

[0039] Table 2

[0040]

[0041]

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com