Modified asphalt adhesive and preparation method thereof

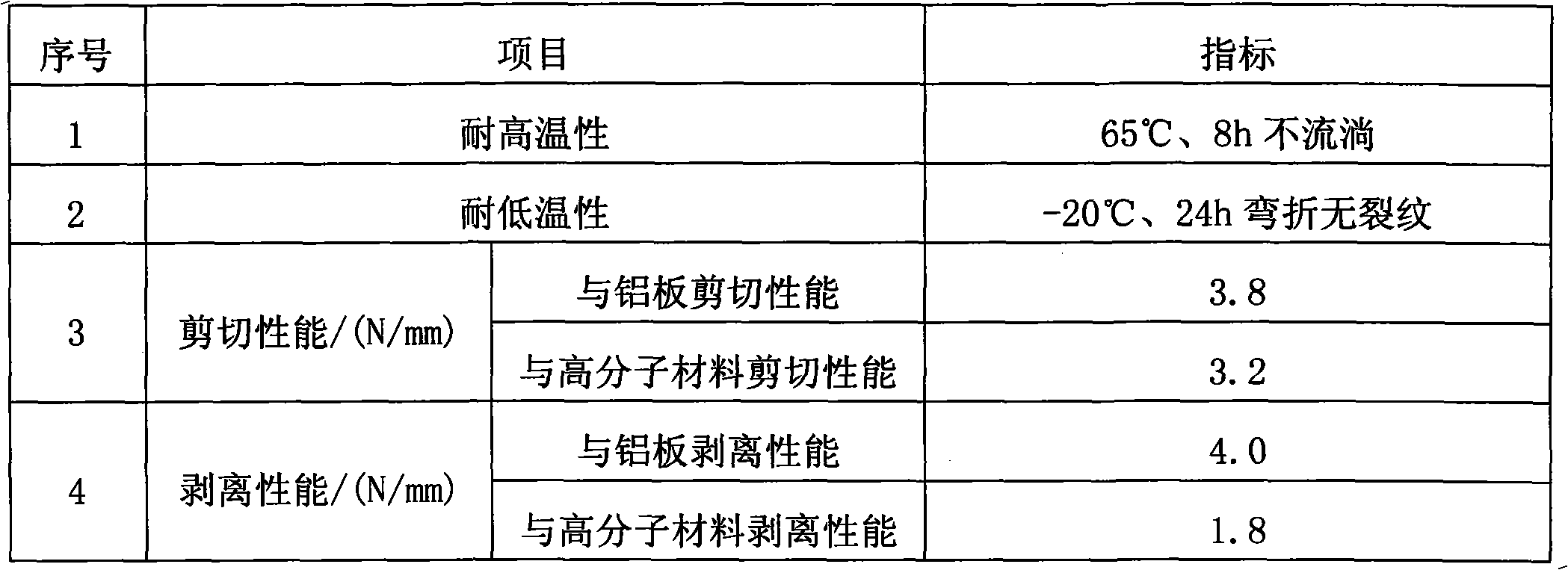

A technology for modifying asphalt and adhesives, applied in the direction of asphalt material adhesives, adhesives, other rubber adhesives, etc. The effect of high temperature and low temperature resistance, strong market competitiveness and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

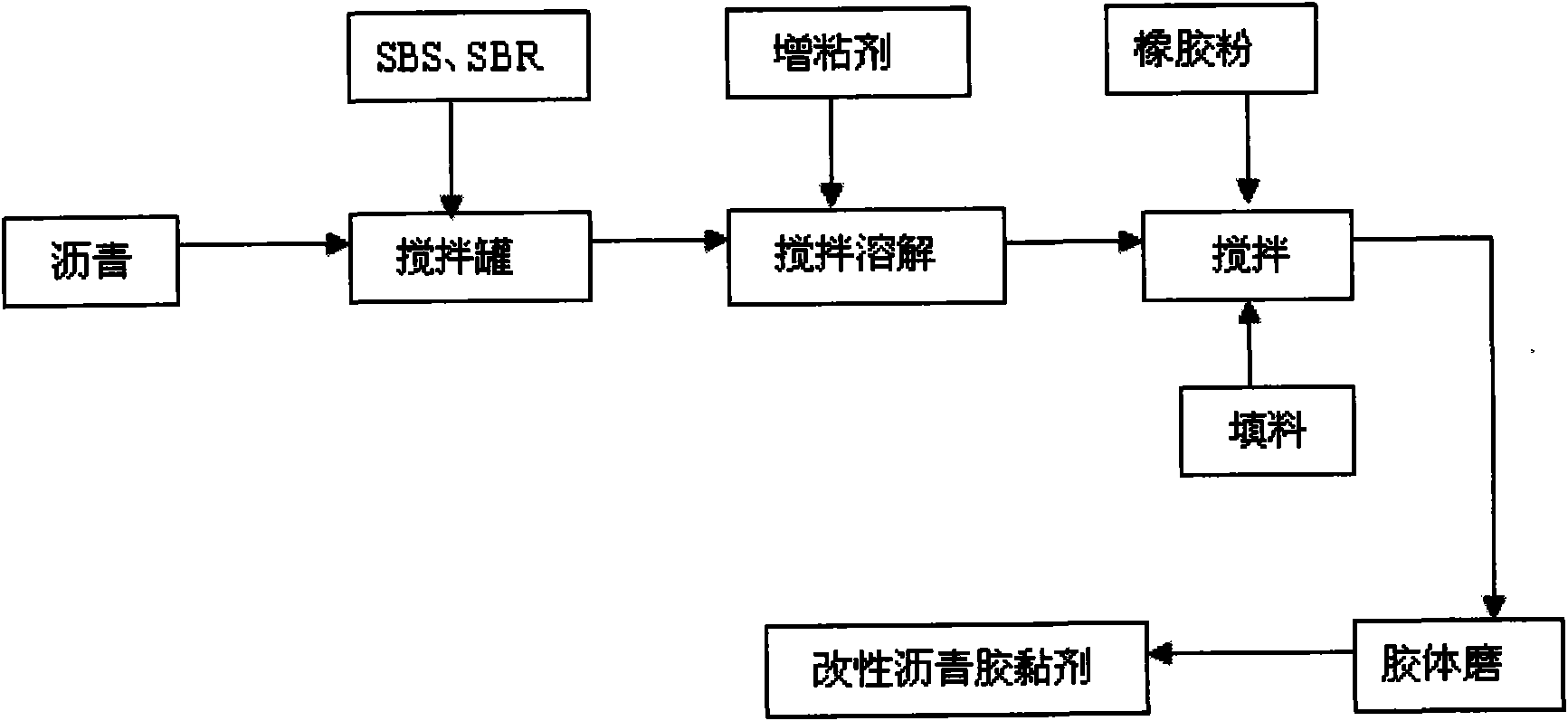

Method used

Image

Examples

Embodiment 1

[0043] Recipe and preparation method:

[0044] 1. Formula:

[0045] Asphalt 450kg

[0046] Tackifier 200kg

[0047] SBS 30kg

[0048] SBR 10kg

[0049] Packing 150kg

[0050] Rubber powder 100kg

[0051] 2. Preparation method:

[0052] First pump 450kg of molten 90# asphalt into the stirring kettle, which is a jacketed stainless steel reactor, heated by heat conduction oil, turn on the stirring paddle, the stirring speed is 100 rpm, and the material temperature is 130°C. Stir for 20 minutes; add 30kg of LG411SBS, 10kg of powdered styrene-butadiene rubber GS-1SBR and continue stirring, raise the temperature to 170°C, stir for 1.5 hours, keep stirring temperature and speed, add 50kg of terpene resin and 150kg of aromatic hydrocarbon Oil, continue to stir for 40 minutes, then add 100kg of 60-mesh rubber powder, 50kg of talc powder and 100kg of calcium carbonate in sequence, continue to stir for 50 minutes, after being ground by a colloid mill, a modified asphalt adhesive w...

Embodiment 2

[0056] Recipe and preparation method:

[0057] 1. Formula:

[0058] Asphalt 450kg

[0059] Tackifier 180kg

[0060] SBS 50kg

[0061] SBR 20kg

[0062] Packing 150kg

[0063] Rubber powder 100kg

[0064] 2. Preparation method:

[0065]First pump 450kg of molten 90# asphalt into the stirring tank, which is a jacketed stainless steel reactor, heated by heat conduction oil, turn on the stirring paddle, the stirring speed is 120 rpm, and the material temperature is 130°C. Stir for 30 minutes; add 50kg of LG411SBS, 20kg of powdered styrene-butadiene rubber GS-1SBR to continue stirring, raise the temperature to 170°C, stir for 1.5 hours, keep stirring temperature and speed, add 80kg of terpene resin and 100kg of aromatic hydrocarbon Oil, continue to stir for 40 minutes, then add 100kg of 60-mesh rubber powder, 50kg of talc powder and 100kg of calcium carbonate in sequence, continue to stir for 50 minutes, after being ground by a colloid mill, a modified asphalt adhesive with ...

Embodiment 3

[0067] Recipe and preparation method:

[0068] 1. Formula:

[0069] Asphalt 450kg

[0070] Tackifier 250kg

[0071] SBS 80kg

[0072] SBR 30kg

[0073] Packing 120kg

[0074] Rubber powder 80kg

[0075] 2. Preparation method:

[0076] First pump 450kg of molten 90# asphalt into the stirring kettle, which is a jacketed stainless steel reactor, heated by heat transfer oil, turn on the stirring paddle, the stirring speed is 100 rpm, and the material temperature is 130°C. Stir for 20 minutes; add 80kg of LG411SBS, 30kg of powdered styrene-butadiene rubber GS-1SBR to continue stirring, raise the temperature to 170°C, stir for 1.5 hours, keep stirring temperature and speed, add 100kg of terpene resin and 150kg of aromatic hydrocarbon Oil, continue to stir for 40 minutes, then add 80kg of 60-mesh rubber powder, 50kg of talc powder and 70kg of calcium carbonate in sequence, continue to stir for 50 minutes, after being ground by a colloid mill, a modified asphalt adhesive with g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com