Resin composition for embedded capacitor, and dielectric layer and metal foil-clad plate manufactured by using same

A resin composition and capacitor technology, applied in the direction of fixed capacitor electrodes, fixed capacitor dielectrics, fixed capacitor parts, etc., can solve the problem of brittleness of composite materials, difficult to line etching machines, and can not meet the processing requirements of embedded capacitor materials and other problems, to achieve the effect of excellent processing performance, avoiding brittleness and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

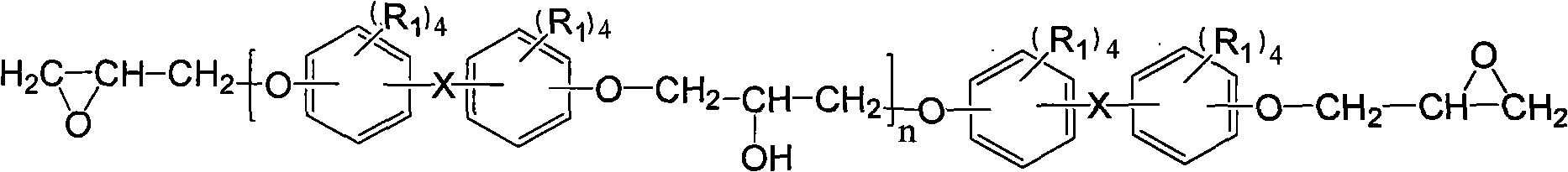

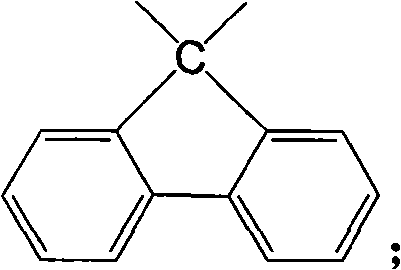

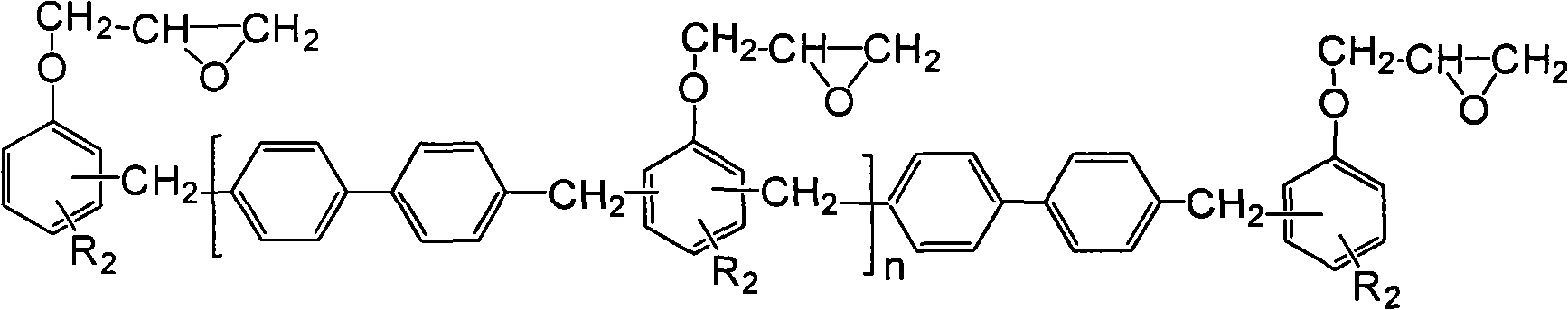

Method used

Image

Examples

Embodiment 1-3

[0072] Bisphenol A epoxy resin (epoxy resin A), brominated epoxy resin (epoxy resin B), and carboxyl-terminated nitrile rubber (C), were dissolved in ethylene glycol methyl ether, and added relative to epoxy The biphenyl phenolic resin and 2-MI (2-methylimidazole) in a molar ratio of 0.9 are mixed at room temperature to obtain a glue solution. The obtained glue solution was coated on the copper foil, and then baked in an oven at 155° C. for 5 minutes to be cured to stage B, so as to obtain a resin composite copper foil. Next, take two resin-composite copper foils and laminate them on the glued side, laminate and cure at 190°C, and measure the tensile modulus, elongation, Tg and peel strength after the cured product is obtained. The specific proportioning and performance of embodiment 1, embodiment 2 and embodiment 3 are shown in table 1.

Embodiment 4

[0078]Dissolve bisphenol A epoxy resin (epoxy resin A), brominated epoxy resin (epoxy resin B), and phenoxy resin mixture in ethylene glycol methyl ether, as for the reaction solution, also added as curing agent 0.9 molar ratio of biphenyl phenolic resin and 2-MI, and then mix the resulting glue at room temperature. Then add 40vol% barium titanate as an additive, mix evenly, then pour the obtained glue on the copper foil, and bake it in an oven at 155°C for 4 minutes to semi-cure to the B stage to make a resin composite copper foil. Next, take two RCCs and put them on top of each other with their adhesive surfaces, laminate and cure at 190°C. After the cured product was obtained, the tensile modulus, elongation, Tg, peel strength, Dk / Df and flame retardancy were measured, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com