Nano transparent heat insulated composite coating material and equipment for testing effect of heat insulation for the material

A composite coating and nano heat insulation technology, which is applied in the field of composite coatings, can solve problems such as poor heat insulation performance, and achieve the effects of strong adhesion, good heat resistance, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

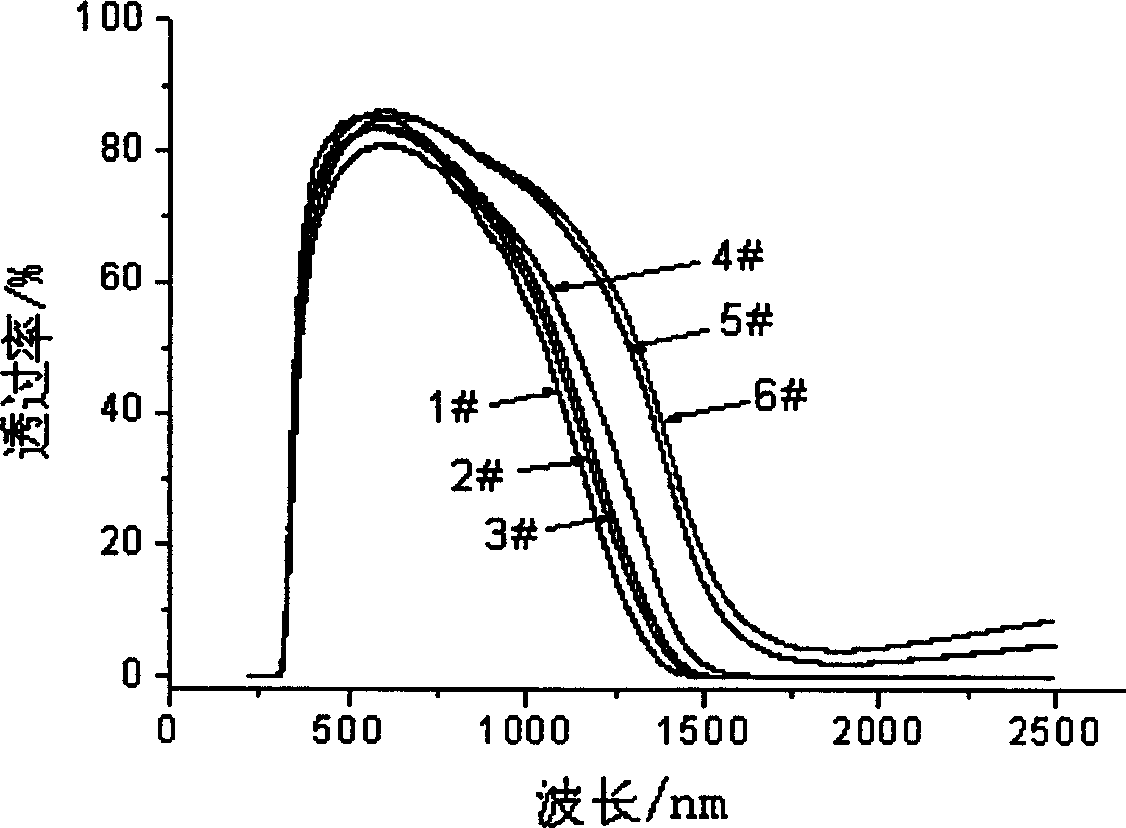

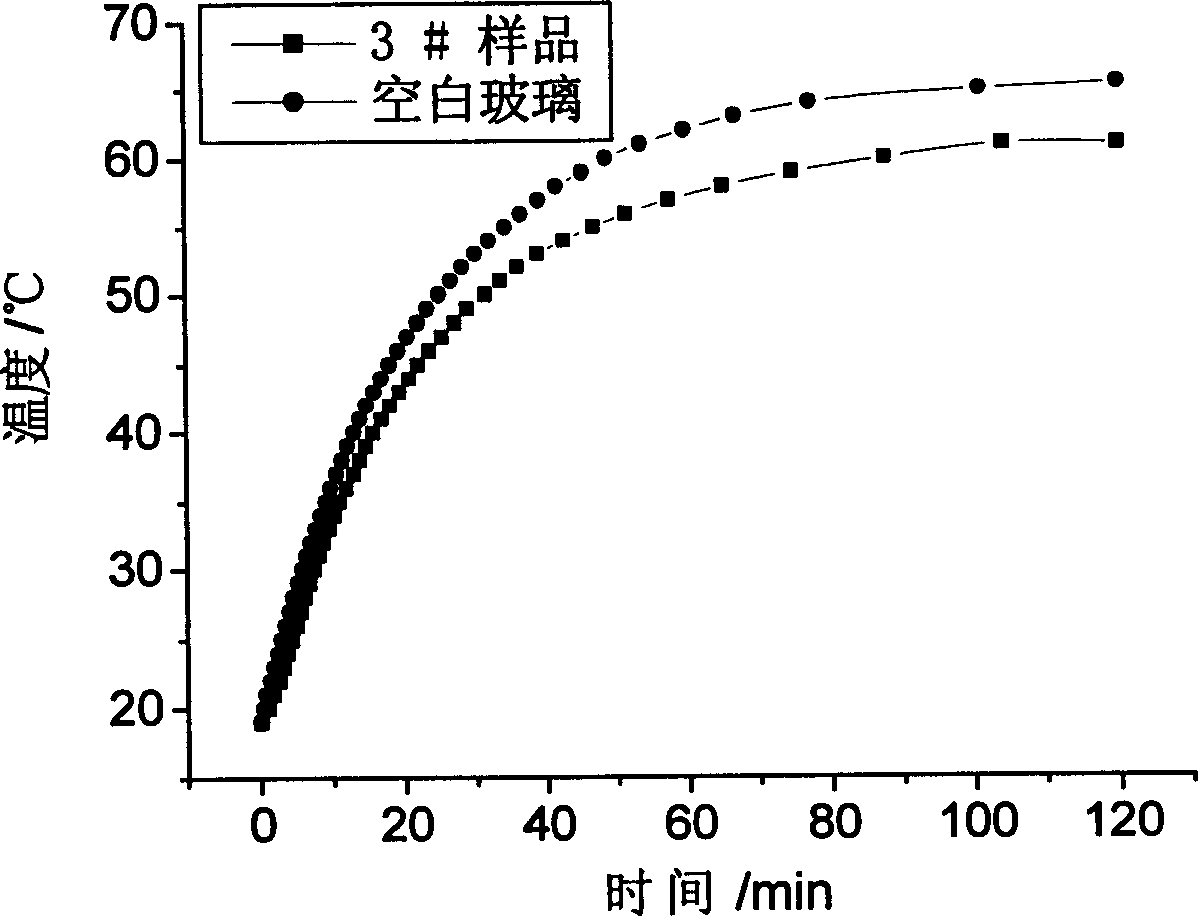

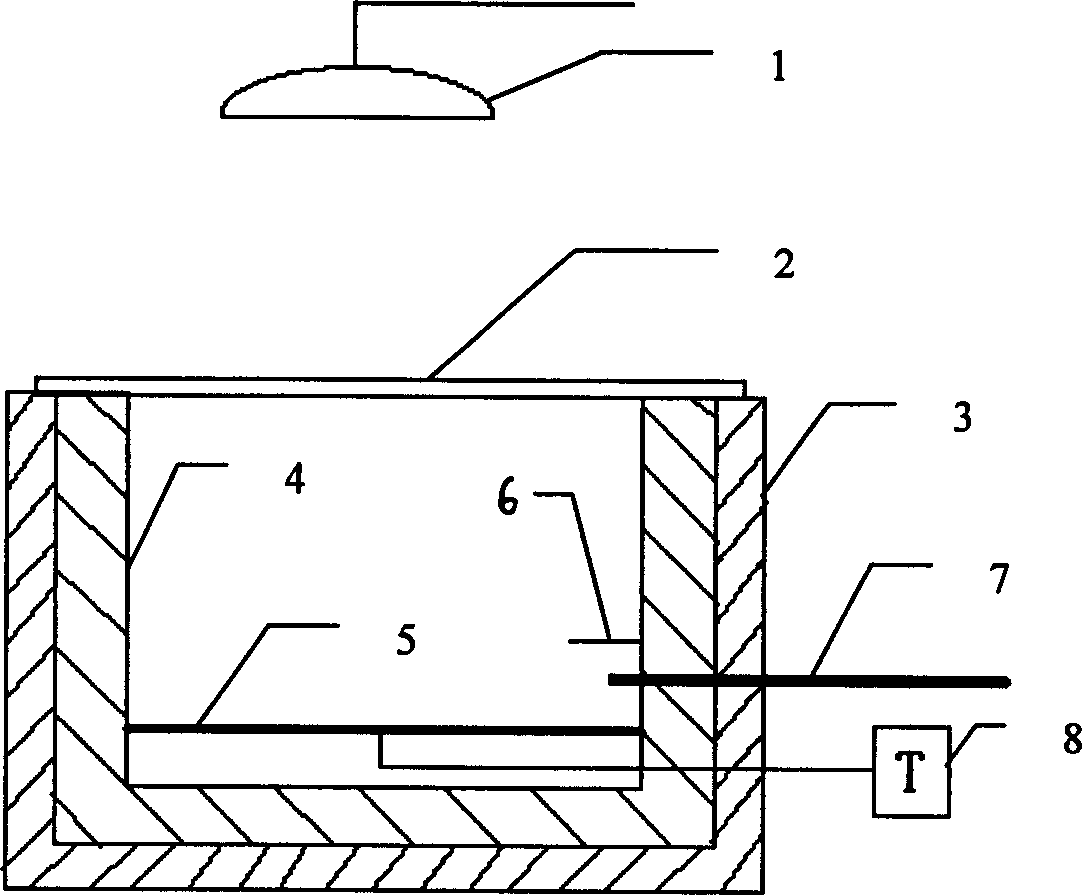

[0028] The present invention is described in detail below in conjunction with embodiment and relevant figure, table. However, the invention is not limited to the examples given. The preparation process of the nano wet paste of the coating of the present invention is: the parts by weight are 5-20 parts of nano indium tin oxide (ITO) or antimony tin oxide (ATO), the parts by weight are 30-50 parts of deionized water, and the parts by weight are 30-20 parts 50 parts of alcohol, 1-3 parts by weight of dispersant and other additives are mixed, dispersed on a high-speed disperser, ball mill for a certain period of time, or dispersed on an ultrasonic generator to obtain a particle size range of 10-60nm and a solid content of 5 - 15% nanometer antimony tin oxide (ATO) water-based wet slurry or nanometer indium tin oxide (ITO) wet slurry with a solid content in the range of 10-20% and a particle size in the range of 10-60nm.

[0029] The present invention provides an embodiment of nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com