Heat resistant ASA (Acrylonitrile-Styrene-Acrylic ester) resin composition and preparation method thereof

A technology of ASA resin and composition, applied in the field of polymer composite materials and preparation, can solve the problems of low thermal deformation temperature and achieve the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

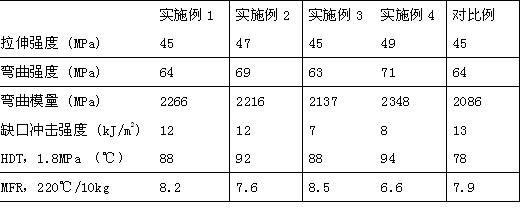

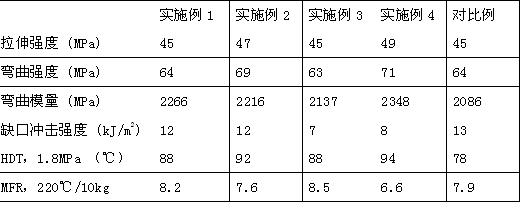

Examples

Embodiment 1

[0026] Example 1: 3000g ASA high rubber powder, 4500g SAN resin (melt index 10g / min, 220°C / 10kg), 2500g α-SMAN copolymer, 15g antioxidant 168, 15g antioxidant 1010, 30g light stabilizer 770 is mixed by a high-speed mixer for 5 minutes, then extruded and granulated in a twin-screw extruder with an aspect ratio of 40 and a diameter of 35mm. The extrusion temperature is 170°C~240°C, and the screw speed is 200~500rpm.

Embodiment 2

[0027] Example 2: 3500g ASA high rubber powder, 2000g SAN resin (melt index 10g / min, 220°C / 10kg), 2000g SAN resin (melt index 28g / min, MFR220°C / 10kg), 2500g NPMI-SAN copolymer, 15g of antioxidant 168, 15g of antioxidant 1010, and 30g of light stabilizer 770 were mixed in a high-speed mixer for 5 minutes, then extruded and granulated in a twin-screw extruder with an aspect ratio of 40 and a diameter of 35mm, and the extrusion temperature was 170°C ~240℃, screw speed 200~500rpm.

Embodiment 3

[0028] Example 3: 3000g ASA high rubber powder, 5000g SAN resin (melt index 10g / min, 220°C / 10kg), 2000g SMA copolymer, 15g antioxidant 168, 15g antioxidant 1010, 30g light stabilizer 770 After mixing by a high-speed mixer for 10 minutes, extrude and granulate in a twin-screw extruder with an aspect ratio of 40 and a diameter of 35mm. The extrusion temperature is 170°C~240°C, and the screw speed is 200~500rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com