Biomass base structure flame retardant polyol and preparation method and application thereof

A structural flame-retardant, biomass-based technology, applied in the field of biomass-based structural flame-retardant polyurethane foam and its preparation, can solve the problems of complex synthesis process, general flame-retardant performance of polyurethane, and poor binding performance of lignin components and polyurethane. Achieve high reactivity, less catalyst consumption, excellent heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

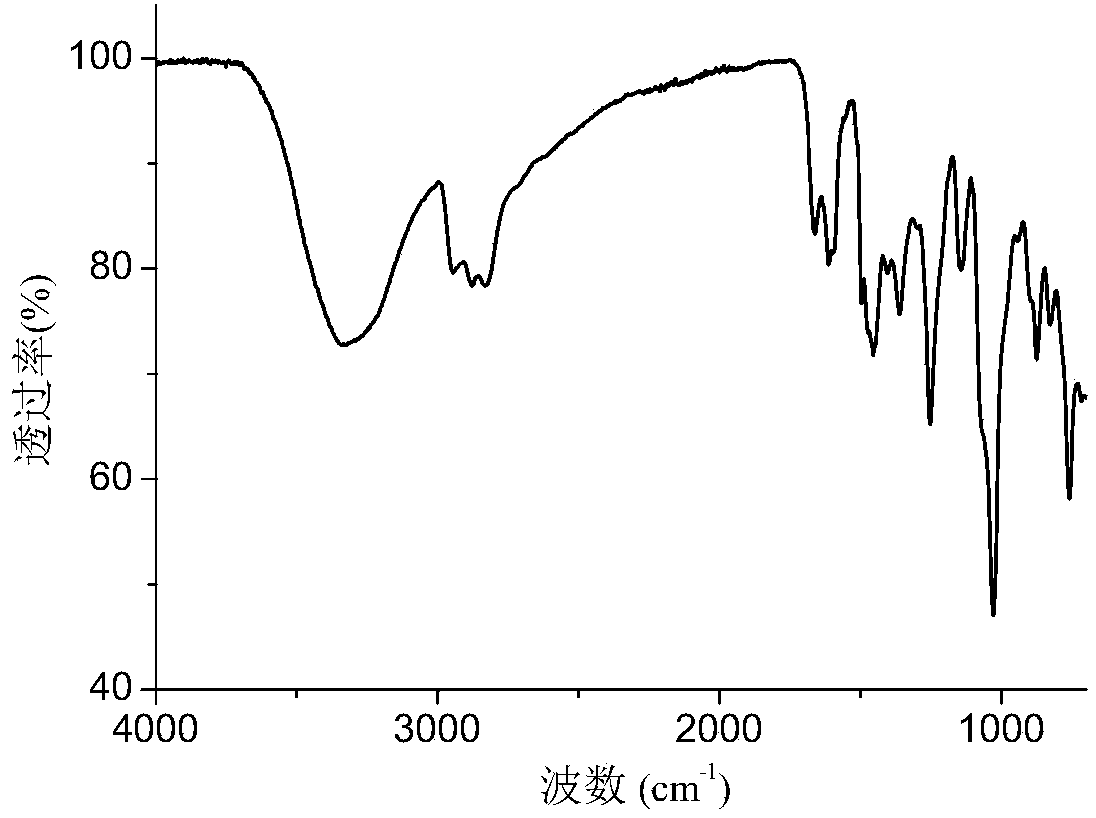

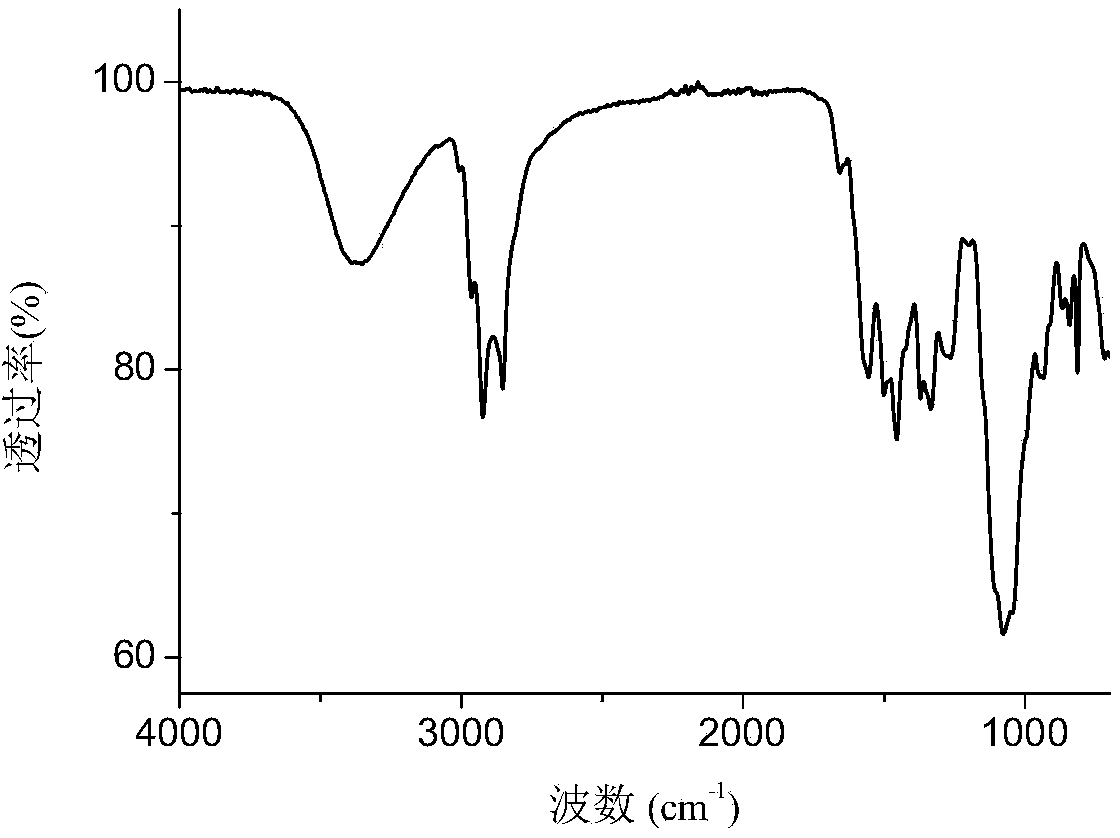

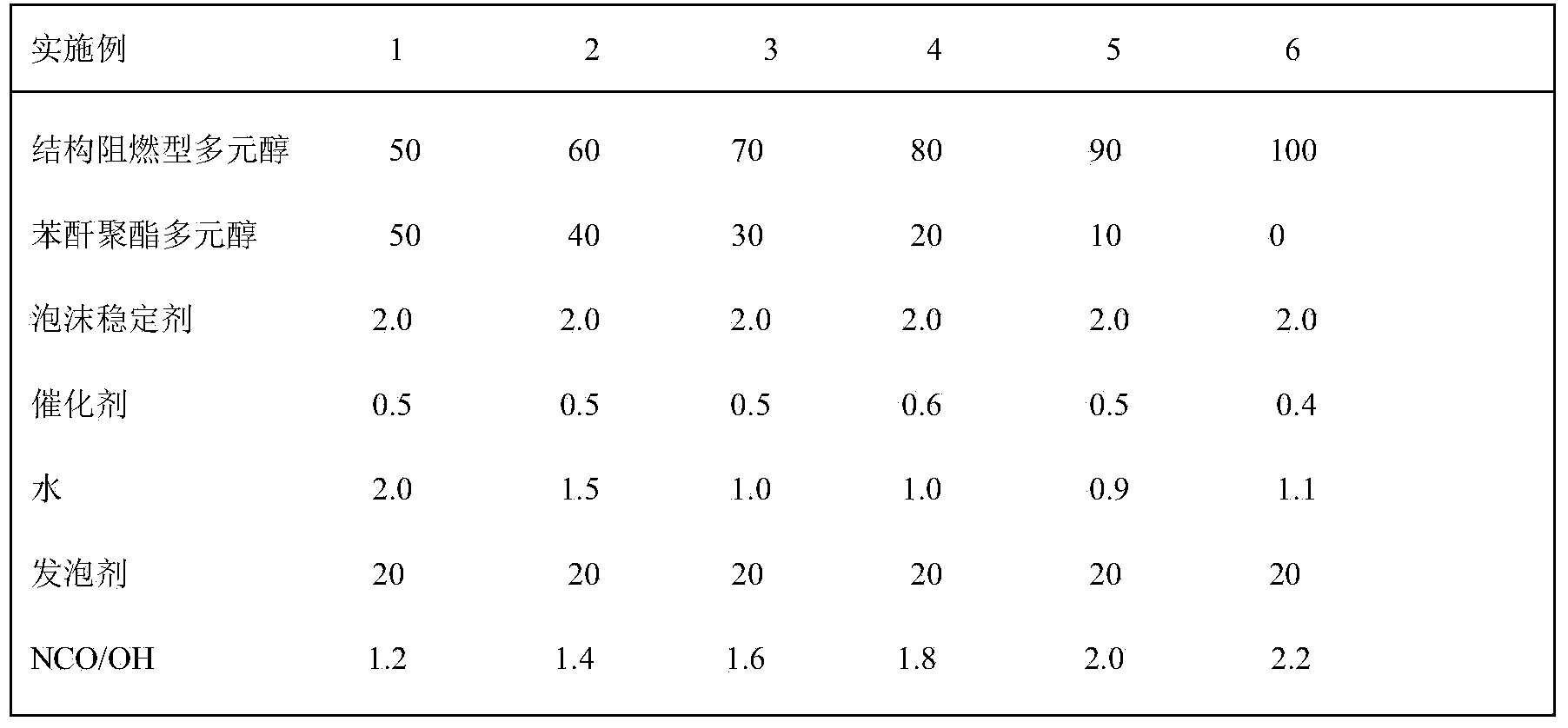

[0018] Add 302g of cardanol and 162g of 37%wt formaldehyde solution into the reactor and mix evenly, raise the temperature to 70°C, add 210g of diethanolamine dropwise, and the dropping time is 1h. Pressure dehydration, when the moisture content is ≤1.5%wt, 66g of ethylene oxide and 87g of propylene oxide are circulated for alkoxylation reaction, the reaction temperature is controlled at 120-130°C, the pressure is controlled at 0.3-0.5MPa, and the ring is completed After oxidizing, react at constant temperature and pressure for 60 minutes. At 120°C / 10mmHg, decompress and evacuate for 30 minutes to obtain a structural flame-retardant polyol with a hydroxyl value of 386mg / g KOH and a viscosity of 2100mPa·s at 25°C. Then obtain the combination polyol according to the preparation formula of rigid polyurethane foam in Table 1, stir evenly, then mix with isocyanate and stir at high speed for 20-30s at a speed of 3000-3500r / min, pour into a mold, and mature for 48h.

Embodiment 2

[0020] Add 302g of cardanol, 60g of paraformaldehyde, and 30g of melamine into the reactor and mix evenly, raise the temperature to 70°C, add 210g of diethanolamine dropwise, and the dropwise addition time is 1h. Dehydration under reduced pressure. When the moisture content is ≤1.5%wt, 80g of ethylene oxide and 97g of propylene oxide are circulated for alkoxylation reaction. The reaction temperature is controlled at 120-130°C and the pressure is controlled at 0.3-0.5MPa. After epoxidation, react at constant temperature and pressure for 60 minutes, and at 120°C / 10mmHg, decompress and evacuate for 30 minutes to obtain a structural flame-retardant polyol. Its hydroxyl value is 406mg / g KOH, and its viscosity at 25°C is 5100mPa·s. Then obtain the combination polyol according to the preparation formula of rigid polyurethane foam in Table 1, stir evenly, then mix with isocyanate and stir at high speed for 20-30s at a speed of 3000-3500r / min, pour into a mold, and mature for 48h.

Embodiment 3

[0022]Add 302g of cardanol, 243g of 37%wt formaldehyde solution, and 60g of melamine into the reactor and mix evenly, raise the temperature to 80°C, add 315g of diethanolamine dropwise, and the dropping time is 2h. ℃, dehydration under reduced pressure, when the moisture content is ≤1.5%wt, 134g ethylene oxide and 163g propylene oxide are circulated for alkoxylation reaction, the reaction temperature is controlled at 120-130℃, and the pressure is controlled at 0.3-0.5MPa, After passing the epoxide, react at constant temperature and pressure for 60 minutes, and at 120°C / 10mmHg, depressurize and evacuate for 30 minutes to obtain a structural flame-retardant polyol. Its hydroxyl value is 460mg / g KOH, and its viscosity at 25°C is 8500mPa·s. Then obtain combined polyol according to the preparation formula of rigid polyurethane foam in Table 1, stir evenly, then mix with isocyanate and stir at high speed for 20-30s at a speed of 3000-3500r / min, pour into a mold, and age for 48h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com