High-temperature-resistant and anti-burn sleeper protective castable

A technology of high temperature resistance and castable, applied in the field of refractory materials, can solve the problems of burning loss, loose track spikes, track deformation, etc., and achieve the effects of excellent sticking iron, good thermal shock resistance and high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

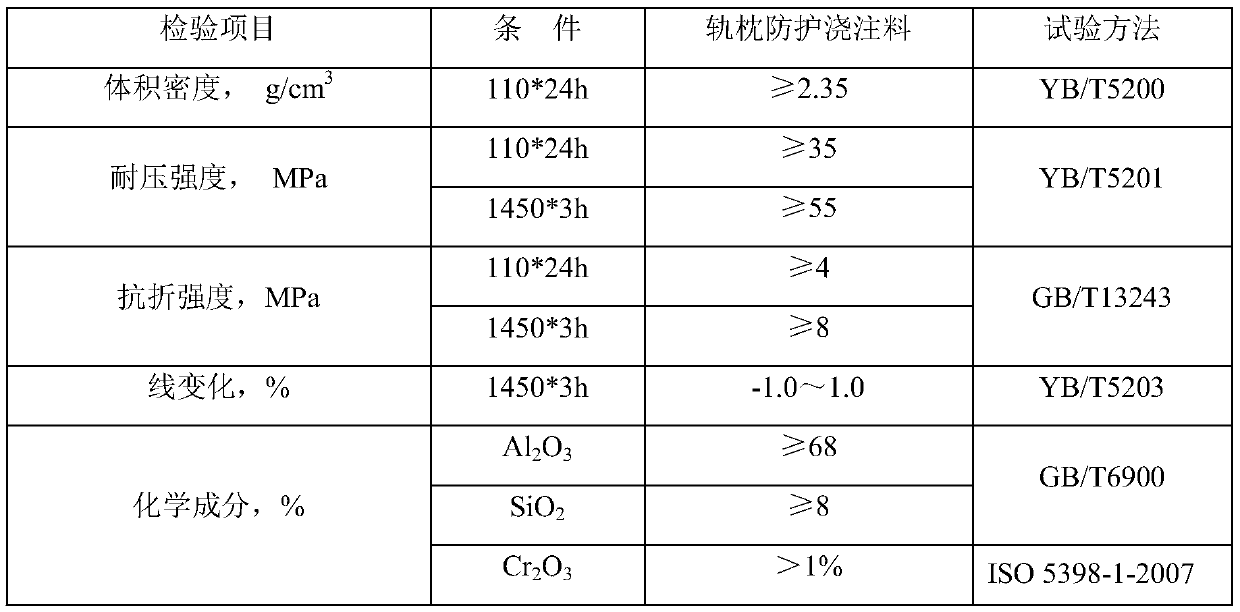

[0047] Send 19% of 3mm-8mm corundum slag, 26% of 2-5mm corundum slag, 11% by weight of 1-3mm burnt gemstone, and 13% of 0.074mm-1mm burnt gemstone into the drum mixer for testing. Mix and stir, after mixing and stirring for 2 minutes, add 9% of 0<particle size≤0.074mm alumina powder, 6% of 0<particle size≤0.005mm activated alumina powder, 8% of 0<particle size≤0.074mm CA60 cement, 2% silica dust powder with 0<particle size≤0.074mm, 2% Guangxi white clay with 0<particle size≤0.074mm, 4% magnesia-chrome brick powder with 0<particle size≤0.074mm and the total of the above raw materials 0.2% by weight of industrial grade sodium hexametaphosphate, 0.4% of stainless steel fiber, and 0.04% of explosion-proof fiber are fed into the drum mixer for mixing and stirring. After mixing and stirring, the mixed material is discharged through the outlet valve Put the device into a dry bag, pack it in 25kg / bag, fasten the opening mark and put it in storage for later use. See Table 4 for the phy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com