Cold trap system for purifying and filling silane

A cold trap and filling technology, applied in the direction of condensation trap/cold partition, liquefaction, silicon hydride, etc., can solve the problems of product particle index exceeding the standard, failure to work, damage to the compressor, etc., to suppress the generation of silica dust , Guarantee the effect of safe and normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

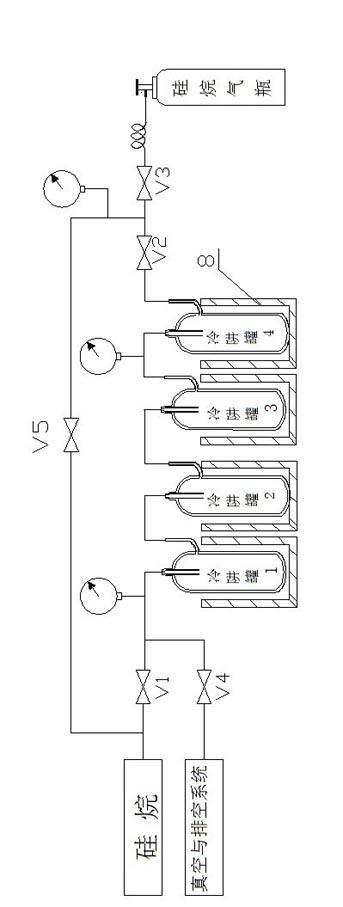

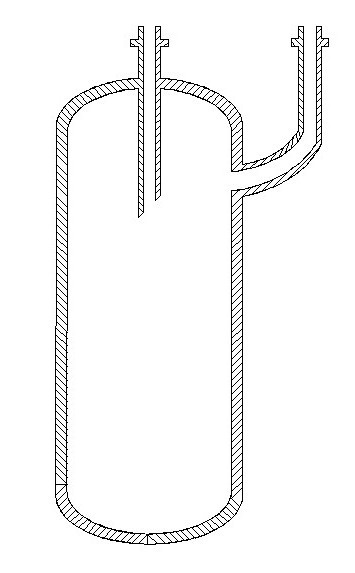

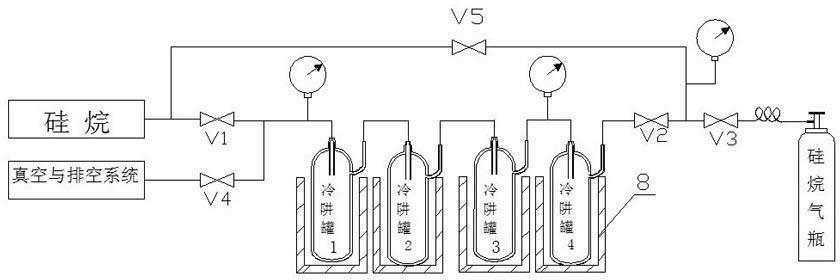

[0009] Such as figure 1 as shown, Cold trap system for silane purification and filling, including four cold trap tanks and four liquid nitrogen Dewars. Such as figure 2 As shown, the cold-trap tank is a closed tank body, the top of the tank body has an air inlet pipe, and the side top of the tank body is provided with an outlet pipe; the outlet pipe of the cold-trap tank is connected with the air inlet pipe of another cold-trap tank, as shown Connect four cold-trap tanks in series; the inlet pipe of the first cold-trap tank is connected with two valves in parallel, one is the silane valve V1, which is connected to the silane gas source, and the other is the vacuum and evacuation valve V4, which is connected to the vacuum and evacuation system . The outlet pipe of the fourth cold-trap tank is connected with the busbar, and the so-called...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com