Tundish cover castable

A castable and cover technology, applied in the field of tundish refractory materials, can solve problems such as structural spalling, low thermal strength, cracks, etc., and achieve the effect of superior thermal shock resistance and good pouring construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

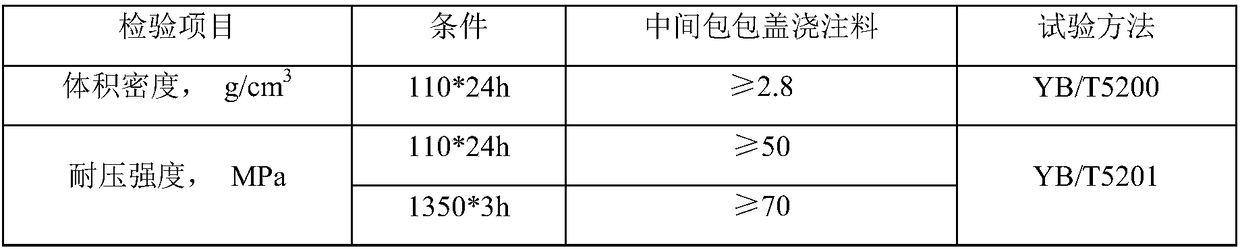

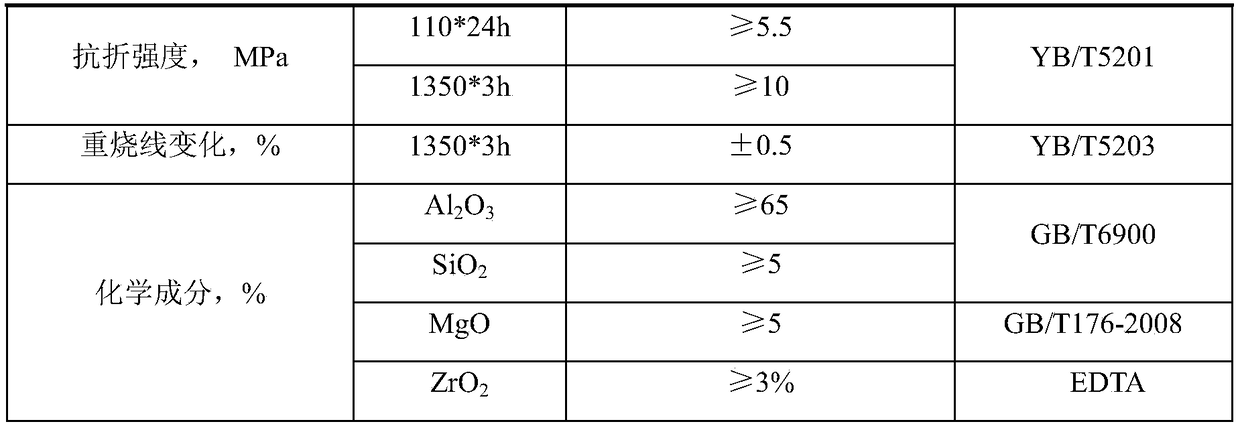

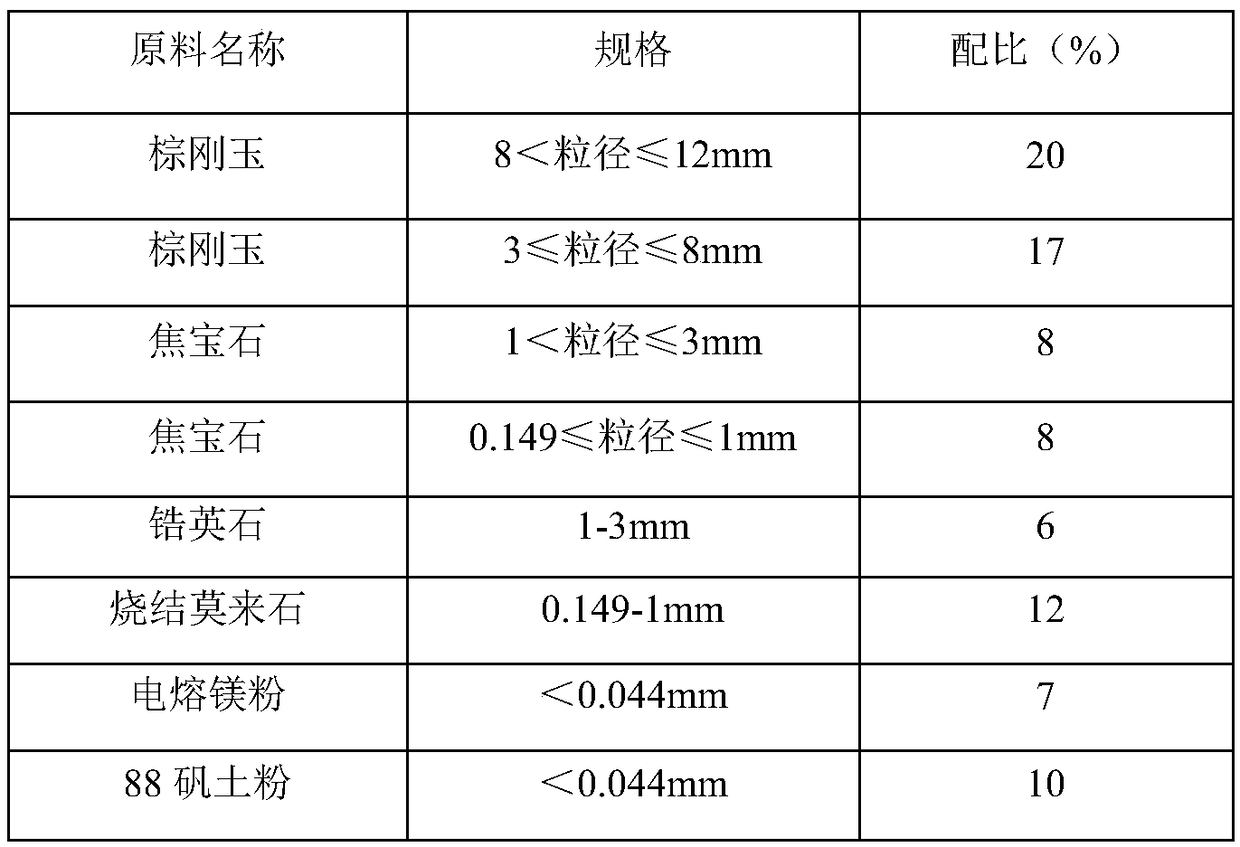

[0038] The raw material of the tundish lid castable of the present invention adopts formula 1, as shown in Table 3. After the raw materials are qualified, they are weighed, stirred and packaged and then sampled and tested. The physical and chemical indicators of the tundish lid castable are shown in Table 4. After being qualified, it will be transported to the tundish construction area for use.

[0039] Table 3 Tundish cover castable formula 1

[0040]

[0041]

[0042] The refractory castable of this embodiment was used as the overall casting material for the tundish cover. This time, 6 tons of the tundish cover castable was sent to the tundish construction area. The data after the overhaul of 3 tundishes and the overhaul data of the original castable were collected. In contrast, the casting performance of the three test tundishes is good, the average water addition is 5.3%, which is 1.2% lower than the average water addition of 6.5% of the original castable. There is no material ...

Embodiment 2

[0046] The raw material of the tundish lid castable of the present invention adopts formula 2, as shown in Table 5. After the raw materials are qualified, they are weighed, stirred and packaged and then sampled and tested. The physical and chemical indicators of the tundish lid castable are shown in Table 6. After being qualified, it will be transported to the tundish construction area for use.

[0047] Table 5 Tundish cover castable formula 2

[0048]

[0049]

[0050] The tundish cover refractory castable of this embodiment is used as the overall refractory refractory castable for the tundish. This time, 4 tons of tundish cover refractory castables are sent to the tundish construction area, and the data and original data of 2 tundish overhauls are collected. Comparing the data of castable overhaul, the two test tundish have good casting performance. The average water addition is 5.2% compared with the original castable 6.4%. There is no material drop during curing and baking, cra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com