Method and apparatus for manufacturing optical fiber perform extramural cladding

A technology of optical fiber preform and outer cladding, which is applied in the field of optical communication, can solve the problems of outer diameter fluctuation and large fluctuation of optical fiber preform outer diameter, and achieve the effects of small outer diameter fluctuation, good cooling effect and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

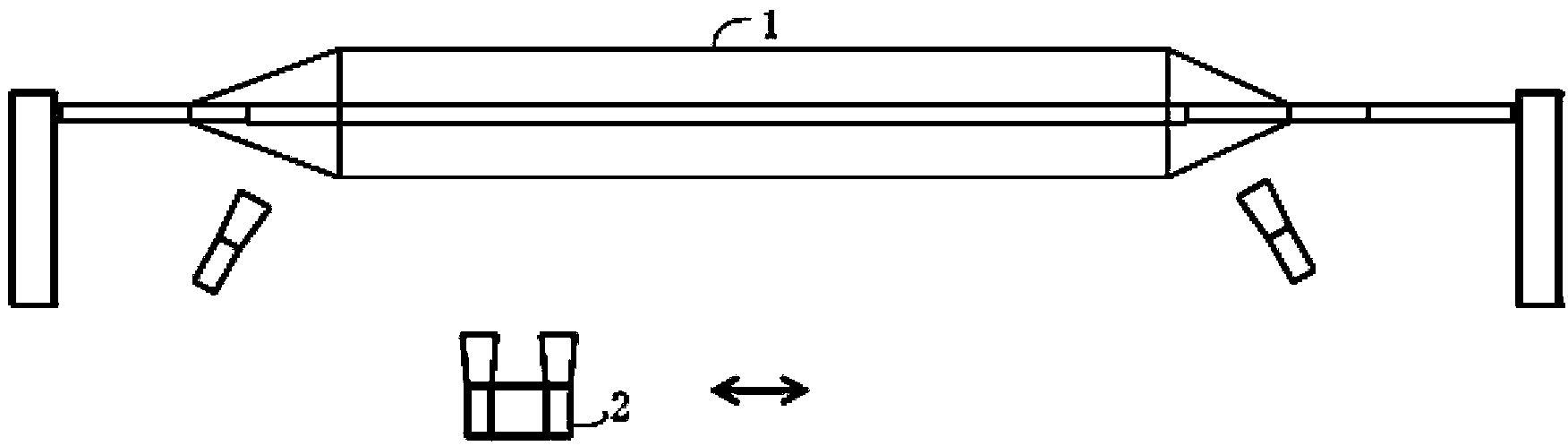

[0079] Example 1: Production under dual-lamp deposition conditions

[0080] Use H 2 , O 2 As combustion gas, SiCl 4 as SiO 2 Raw materials generated by dust are fed in at a certain flow rate figure 1 For the deposition lamp shown, the distance between the lamps is 200mm, the traverse distance is 1200mm, the initial layer traverse speed is 100mm / min, and the traverse speed is gradually increased to 900mm / min, and remains unchanged. The characteristics of the preform are as follows:

[0081] Dust preform density: 0.52g / cm3.

[0082] Deposition rate: 30g / min.

[0083] Bubble defects: None.

[0084] Maximum corrugation on the surface of glass preform (between adjacent 40mm): 0.1mm.

[0085] The characteristics of the optical fiber preform described in Example 1 all meet the requirements of relevant standards.

example 2

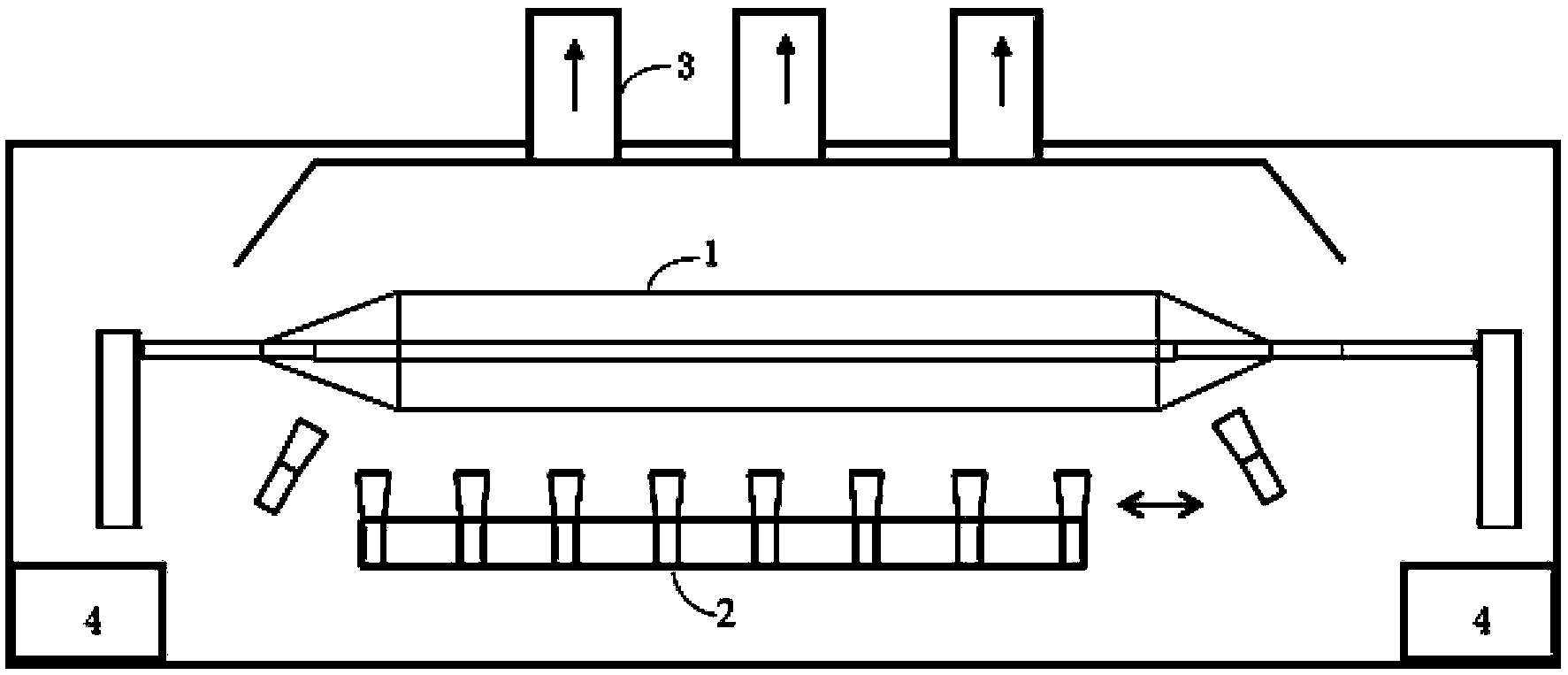

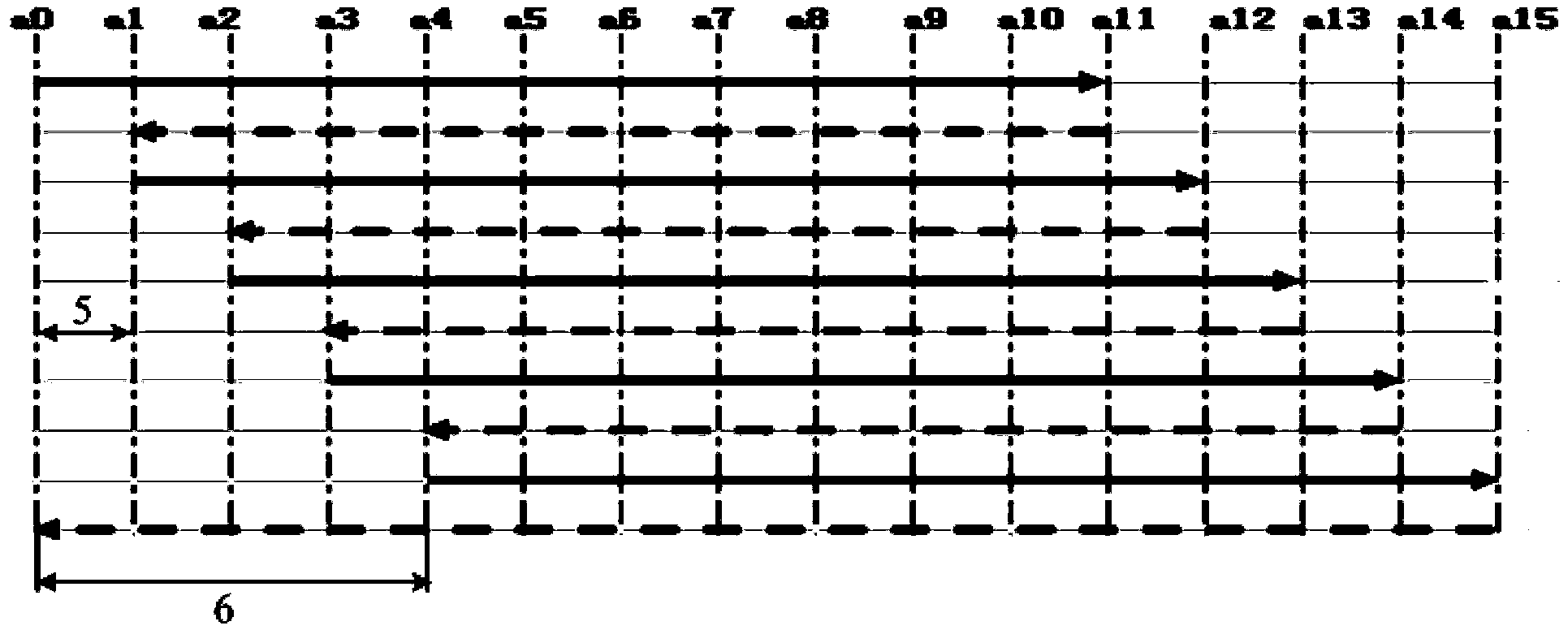

[0086] Example 2: Multi-lamp deposition production with lateral offset

[0087] Use H 2 , O 2 As combustion gas, SiCl 4 as SiO 2 Raw materials generated by dust are fed in at a certain flow rate figure 2 For the deposition lamp array shown, the lamp distance is 200mm, according to V=2RL 0 / (2N+1), the traversing speed is 960mm / min, the initial layer traversing speed is 100mm / min, gradually increase to the traversing speed 960mm / min, the traversing distance is 200mm, and the same distance is offset each time, and the test is 3 times , 2 of which cracked at 15Kg, and the result of 1 uncracked is as follows:

[0088] Dust preform density: 0.55g / cm3.

[0089] Deposition rate: 80g / min.

[0090] Bubble defects: None.

[0091] The maximum corrugation on the surface of the glass preform (between adjacent 40mm): 0.2mm.

[0092] The characteristics of the optical fiber preform described in Example 2 meet the requirements of relevant standards. The deposition rate of a single r...

example 3

[0093] Example 3: Multi-lamp deposition production with lateral movement and gas flow control

[0094] Use H 2 , O 2 As combustion gas, SiCl 4 as SiO 2 Raw materials generated by dust are fed in at a certain flow rate figure 2 For the deposition lamp array shown, the lamp distance is 200mm, according to V=2RL 0 / (2N+1), the traversing speed is 960mm / min, the initial layer traversing speed is 100mm / min, and gradually increases to the traversing speed 960mm / min, the traversing distance is 200mm, and each time the offset is the same distance, with the traversing The speed changes, and the combustion gas flow is adjusted accordingly, that is, the gas flow increases synchronously when the speed increases. The test is performed 3 times, and the tests are all successfully completed. The characteristics of the optical fiber preform produced are as follows:

[0095] Optical fiber preform density: 0.60g / cm3.

[0096] Bubble defects: None.

[0097] Maximum corrugation on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com