Dust Scrubber for Treatment of Fumed Silica Tail Gas

A technology of fumed silica and washing tower, which is applied in chemical instruments and methods, using liquid separating agent, dispersing particle separation, etc., can solve the problems of small operation flexibility and small processing capacity of a single set of devices, and achieves high tower operation flexibility. , The effect of washing and dust removal is good, and the effect of ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

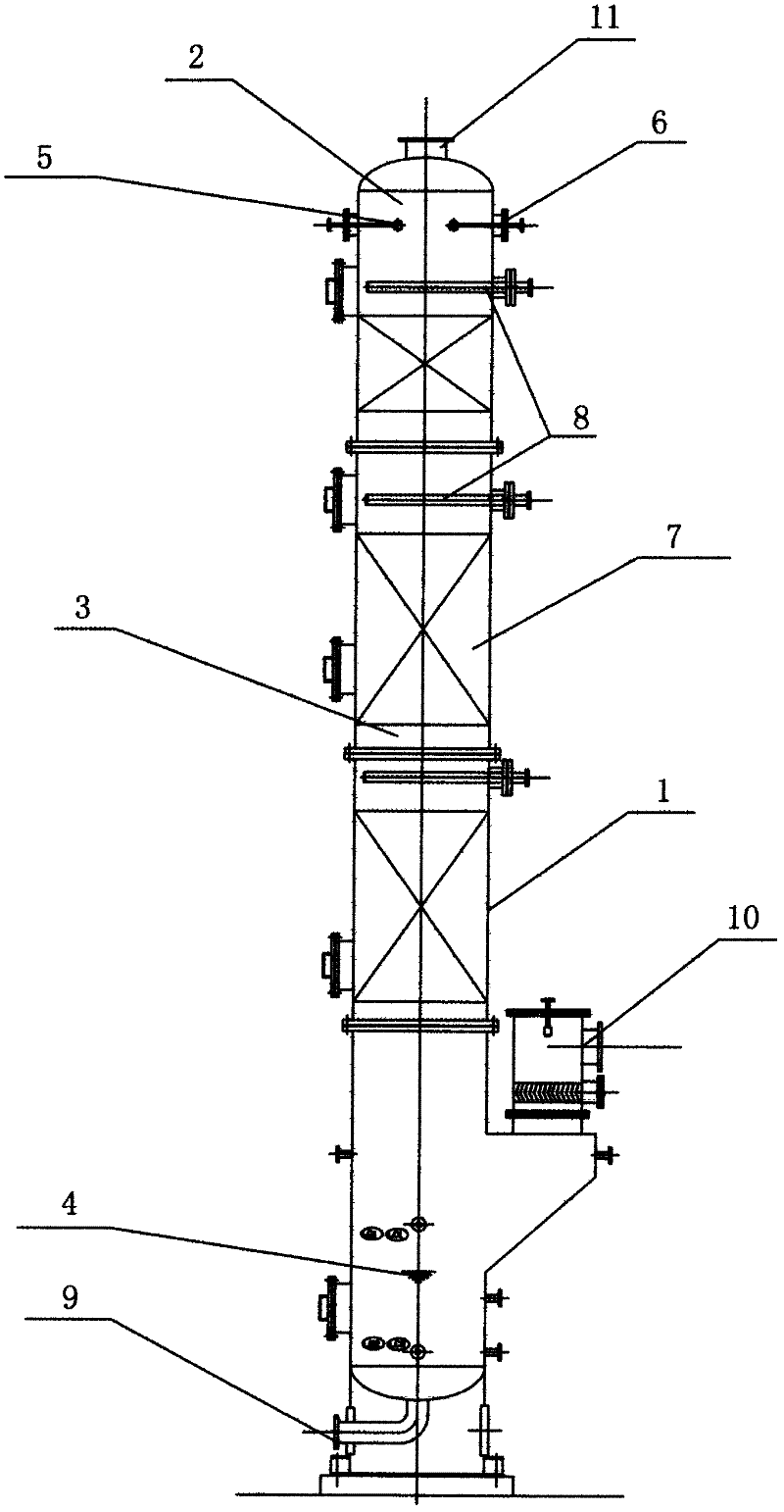

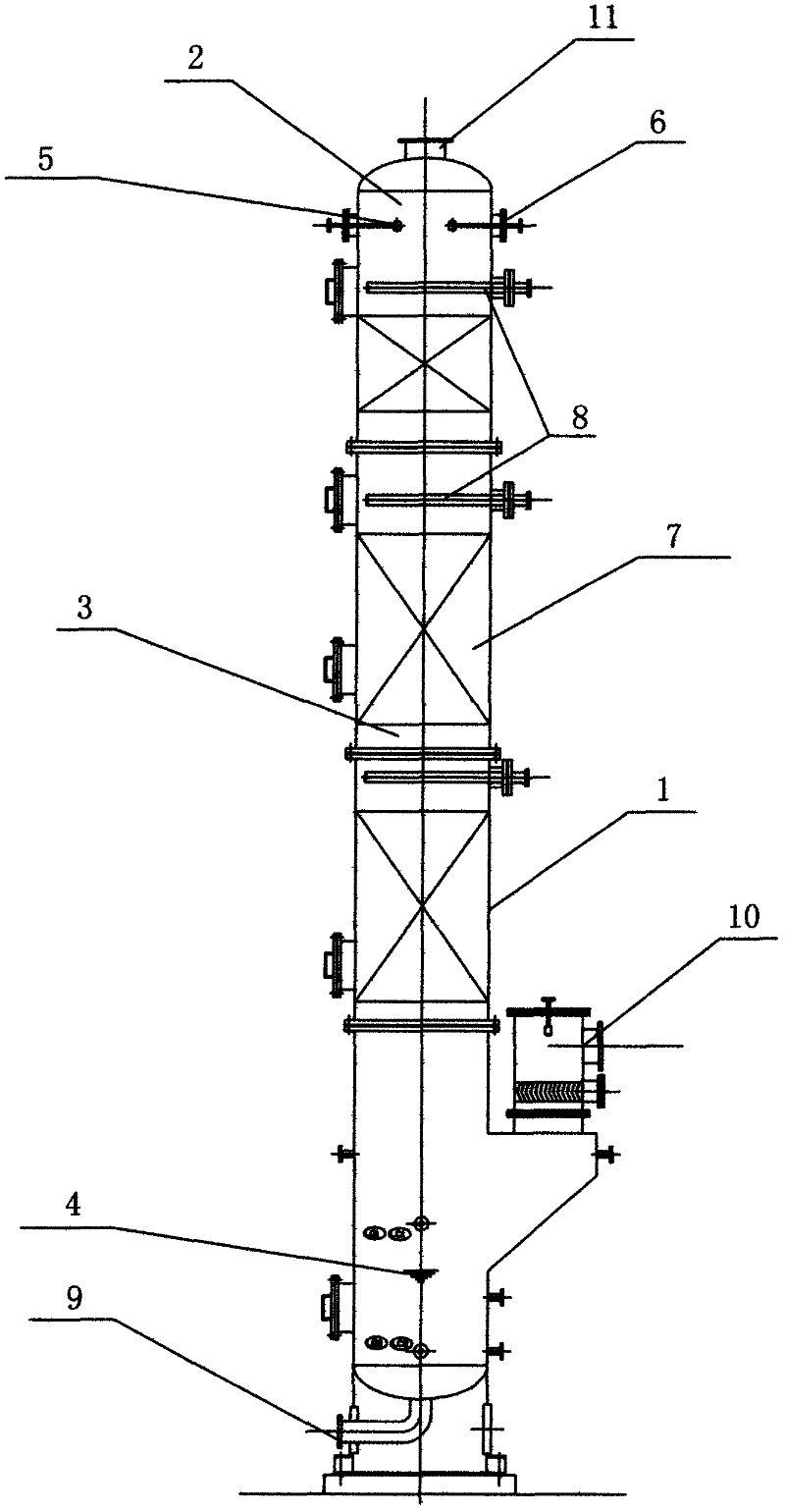

[0023] Such as figure 1 As shown, a dust removal and washing tower for treating gas-phase silica tail gas includes a tower body 1, and the tower body 1 is divided into a spray washing section 2, a packing absorption washing section 3 and a storage liquid from top to bottom. Section 4, spray washing section 2 is provided with industrial primary water nozzle 5 and dilute acid nozzle 6; packing absorption washing section 3 is longitudinally provided with three grid packings 7, and above the grid packings are respectively provided with concentrated acid distributors 8; The bottom of the liquid storage section 4 is provided with a concentrated acid outlet 9, the side of the tower body between the liquid storage section and the packing absorption washing section is provided with a mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com