A Spiral Nozzle Applicable to Wet Electrostatic Precipitator and Its Arrangement

A wet electrostatic precipitator and spiral technology, used in electrostatic separation, electrode cleaning, etc., can solve the overlapping of spray distribution, the nozzle setting spacing, the surface of the dust collecting electrode cannot be completely covered by the spray liquid, and the spray is uneven, etc. problems, to achieve the effect of saving investment and operating costs, good cleaning and dust removal, and reducing the number of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

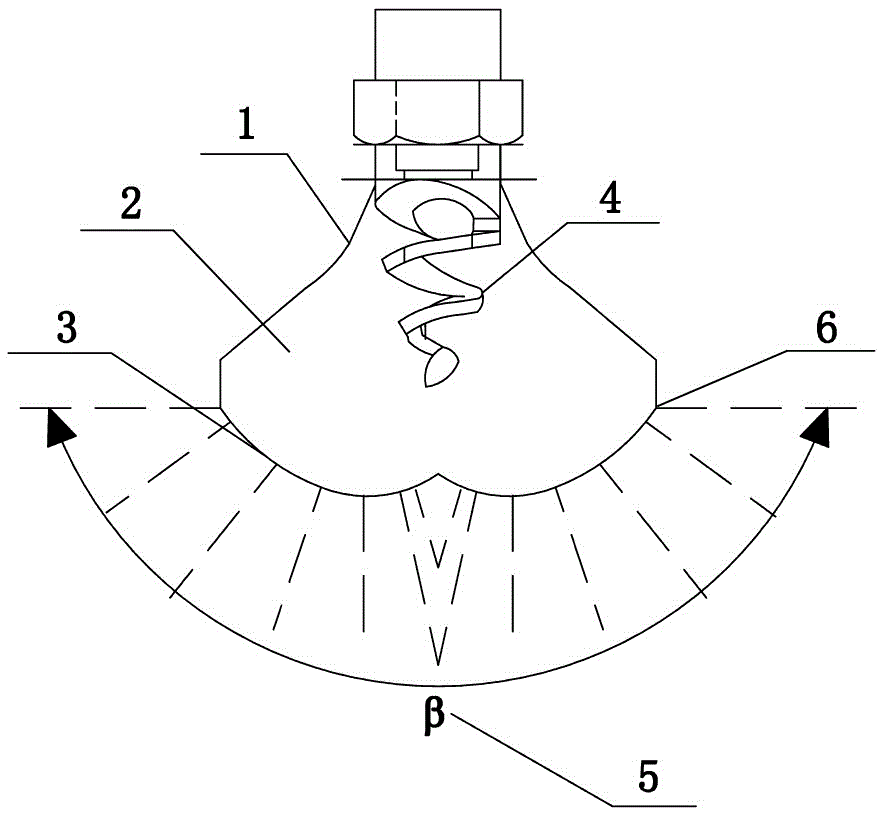

[0026] figure 1 It is a structural schematic diagram of the spiral nozzle suitable for the wet electrostatic precipitator proposed by the present invention. Such as figure 1 As shown, the structure of the spiral nozzle includes a spiral nozzle 4 and a spray housing 2, the spiral nozzle 4 is placed in the inner cavity of the spray housing 2, and the bottom of the spray housing 2 is a spray surface 3, which is convex and symmetrical Double spherical structure, the surface is uniformly arranged with a plurality of spray holes perpendicular to the radial direction of the spherical surface of the spray surface 3, from figure 1 It can be seen that the spray angle β5 can reach up to 180°.

[0027] figure 1 The spray mode of the spiral nozzle 1 can be set as an intermittent mode or a continuous mode.

Embodiment 2

[0029] The spiral nozzle 1 of the present invention is used in wet electrostatic precipitators as a dust collector cleaning device for flat, tubular or honeycomb wet electrostatic precipitators, or as a cleaning device for corona electrodes of wet electrostatic precipitators.

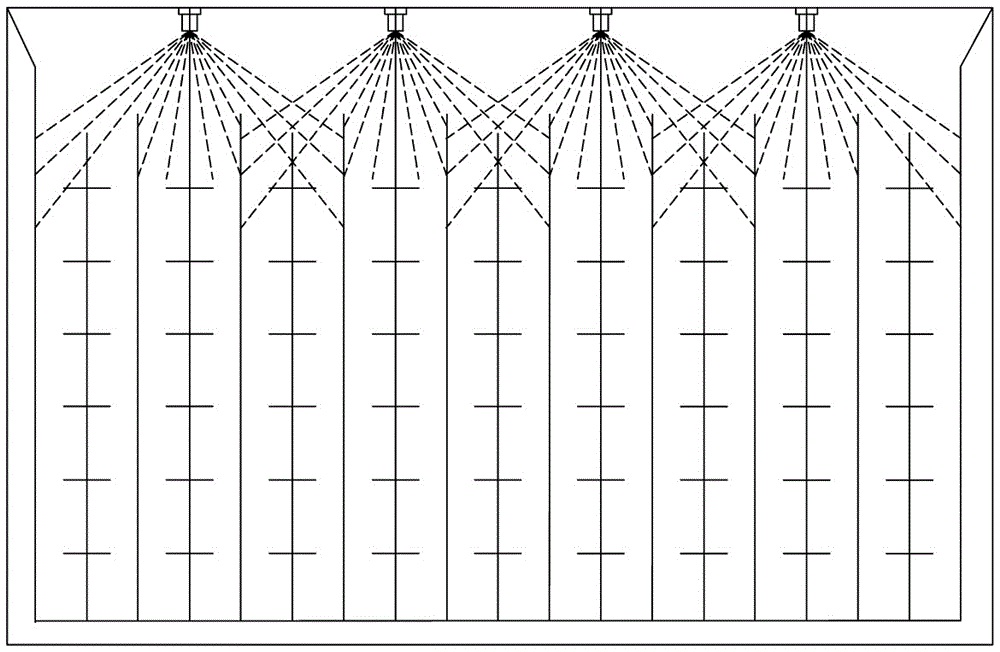

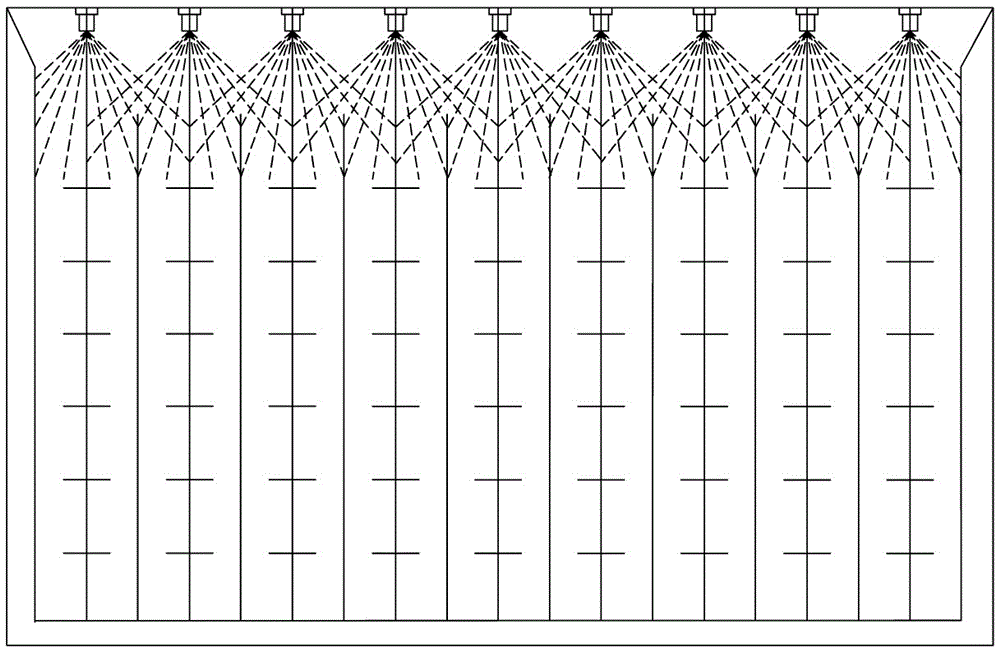

[0030] figure 2 with image 3 It is a schematic diagram of the two arrangement positions of the existing common nozzles in the plate structure wet electrostatic precipitator. When the installation arrangement distance of common nozzles is too large, which is equal to (or greater than) two dust collection channels 10 (a dust collection channel is formed between two rows of dust collection electrodes), such as figure 2 As shown, it is easy to cause the surface of some dust collectors to be unable to be completely covered by the spray liquid, and there will be a spray "dead angle", and a complete and smooth water film cannot be formed; if the arrangement distance of ordinary nozzles is reduced, such as ...

Embodiment 3

[0034] The arrangement positions of the spiral nozzle 1 proposed by the present invention in the honeycomb structure wet electrostatic precipitator (taking the rhombus structure as an example) are as follows Figure 5 , 6 , 7, 8 shown.

[0035] Figure 5 Shown is a schematic diagram of the arrangement position of the spiral nozzle 1 in a diamond-shaped structure (a kind of honeycomb) wet electrostatic precipitator, which is represented by Figure 5 It can be seen that the spiral nozzles 1 are arranged above the common corner of the rhombus-shaped dust collection pole 7, and the cross-sectional schematic diagram of the spray distribution range of this arrangement is as follows: Image 6 shown, from Image 6 It can be seen that each dust collecting pole can be covered by spraying.

[0036] Figure 7 It is a schematic diagram of another arrangement position of the spiral nozzle 1 in the diamond-shaped wet electrostatic precipitator, that is, the spiral nozzle 1 is placed abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com