System and control method for automatically compounding cement paste

A kind of cement slurry and mixing technology, applied in the direction of control device, etc., can solve the problems of affecting the quality of slurry mixing, high labor intensity, complicated operation of cement slurry, etc., and achieve the effect of ensuring the quality of slurry mixing and highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

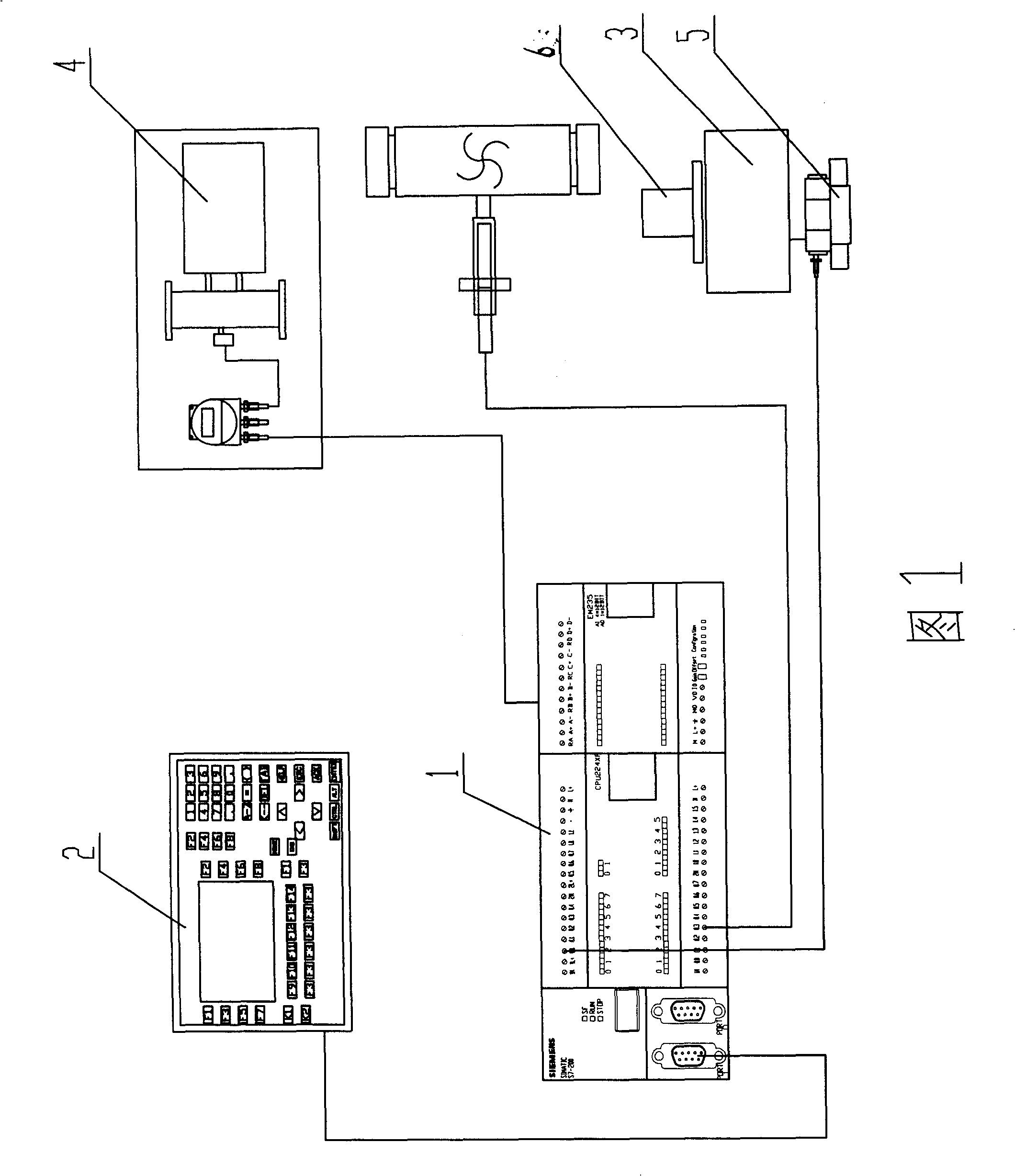

[0019] Embodiment 1, referring to Figures 1 and 2, the microprocessor 1 with the preset program is connected to the man-machine interface 2, the solenoid valve 5 of the lower ash valve oil cylinder and the density meter 4 respectively through lines, and the solenoid valve 5 of the lower ash valve oil cylinder is connected to the lower ash valve oil cylinder. The ash valve 3 is connected, and the ash valve angular displacement sensor 6 is installed on the ash valve 3. The ash valve 3 is used to control and measure the flow of dry cement. The density meter 4 is used to accurately measure the actual density of the cement slurry. The microprocessor 1 passes MPI bus and man-machine interface 2 can realize man-machine communication;

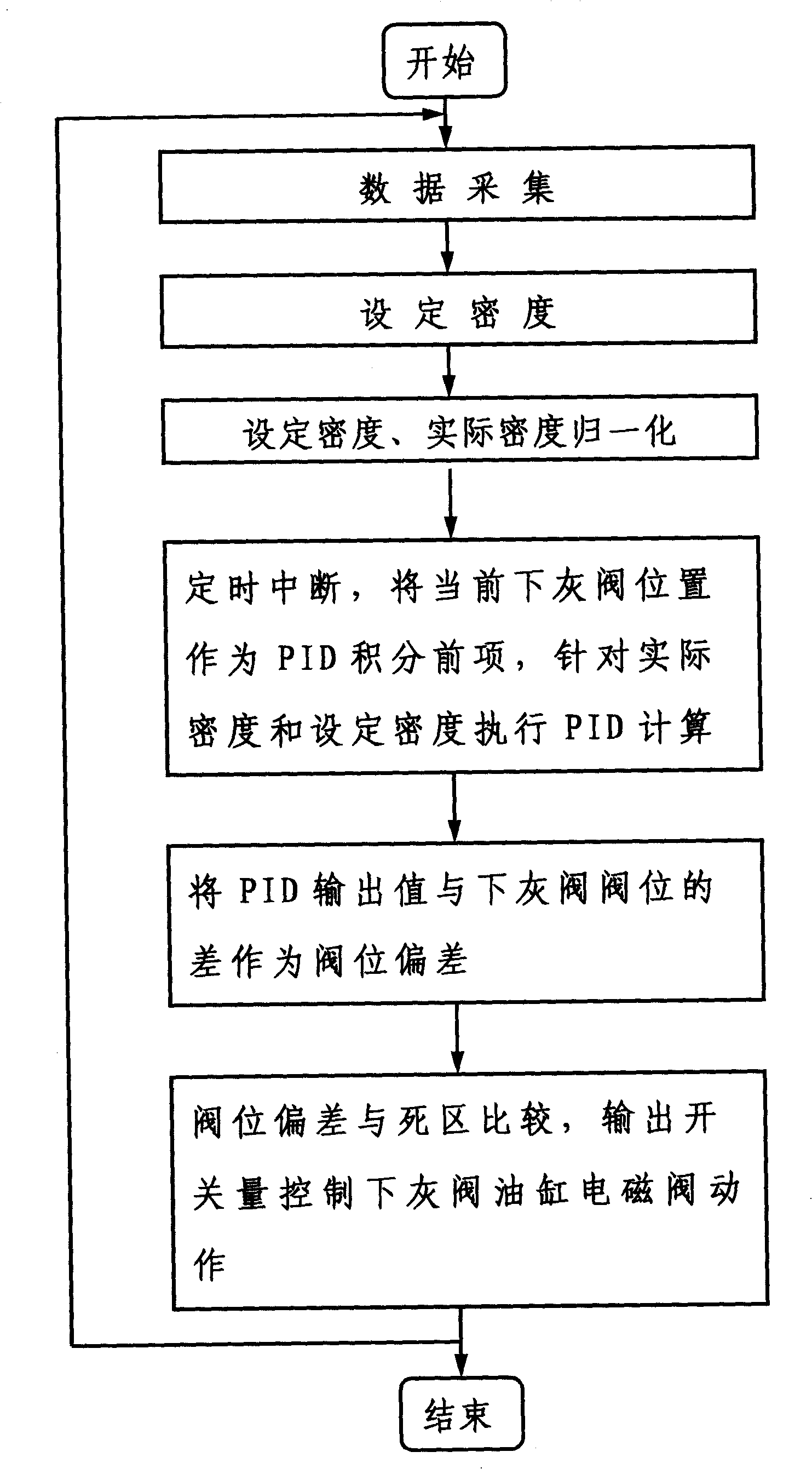

[0020] In the control method of the above-mentioned automatic mixing cement slurry system, the density of the cement slurry is controlled according to the following steps:

[0021] 1.1 Data acquisition, collecting cement slurry density signal and ash v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com