Plating method for laser high-reflective film

A high-reflection film and laser technology, applied in the field of vacuum coating, can solve the problems that cannot directly reflect the strength of the mirror against laser damage, the damage threshold of the reflective film, etc., to achieve no wavelength drift, increase the damage threshold, and reduce absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0027] The invention includes two parts: the preparation of the mixed film material and the plating process of the laser high reflection film, and the difficulty of the plating process is greatly reduced by using the mixed film material.

[0028] (1) Membrane material preparation and testing

[0029] 1. Select three commonly used high-refractive index elemental thin film materials:

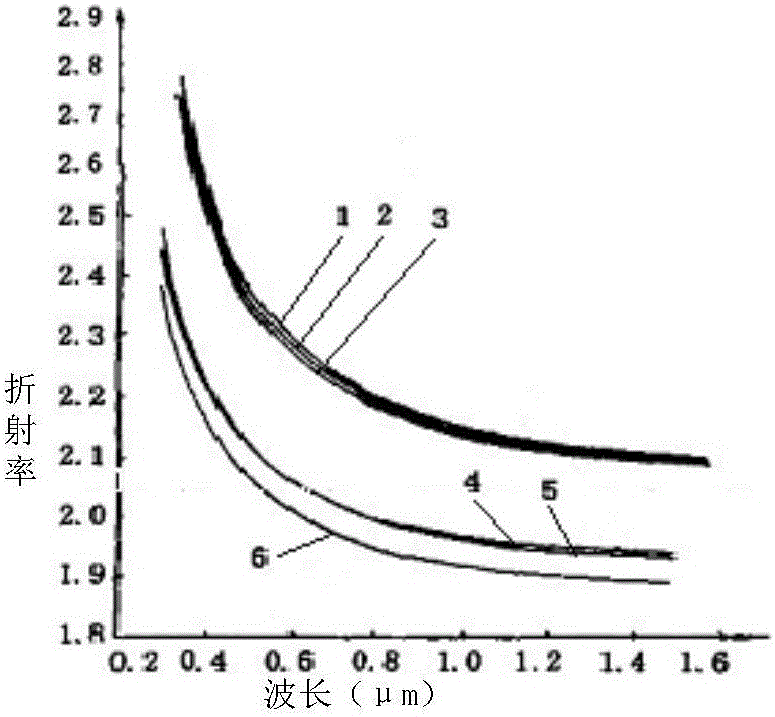

[0030] TiO 2 The refractive index is between 2.2-2.7, and the refractive index depends strongly on the plating method and substrate temperature, but its compactness is average, and the laser damage threshold is low.

[0031] Ta 2 o 5 The refractive index is between 2-2.2, but the film layer is extremely dense, the filling density tends to be 1, and the laser destruction threshold is slightly higher than that of TiO2.

[0032] ZrO 2 The refractive index is between 1.9-2.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com