Wire winding machine precision wire winding device

A wire arrangement device and wire take-up machine technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the drift of the wire, the uneven size of the gap between the wires, the surface of the cable wire and the clamping wire, etc. problem, to achieve the effect of improved cable arrangement, simple installation method, no overlapping and drifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

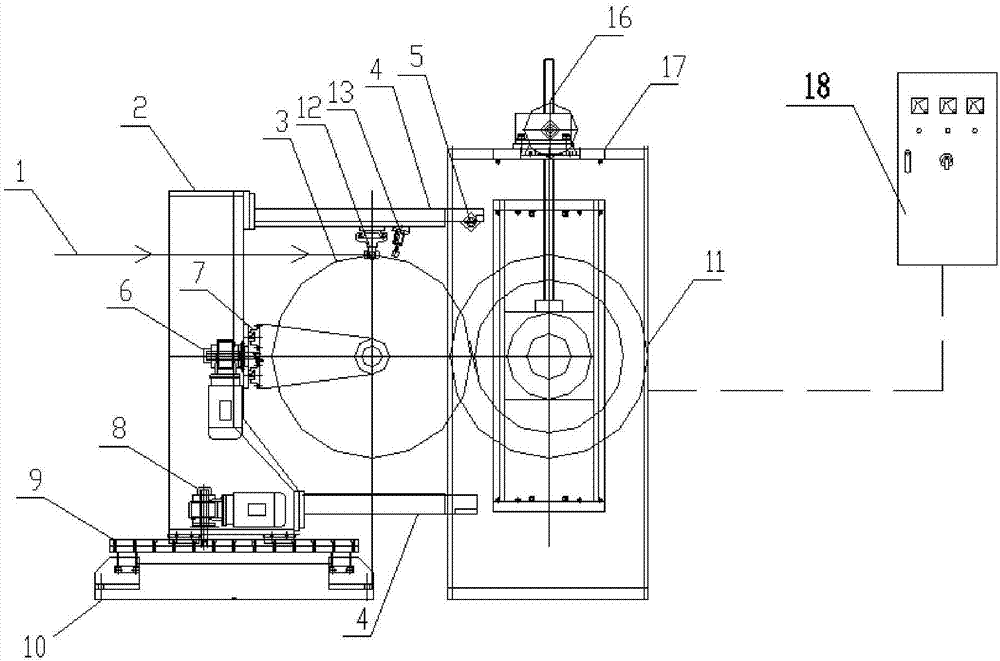

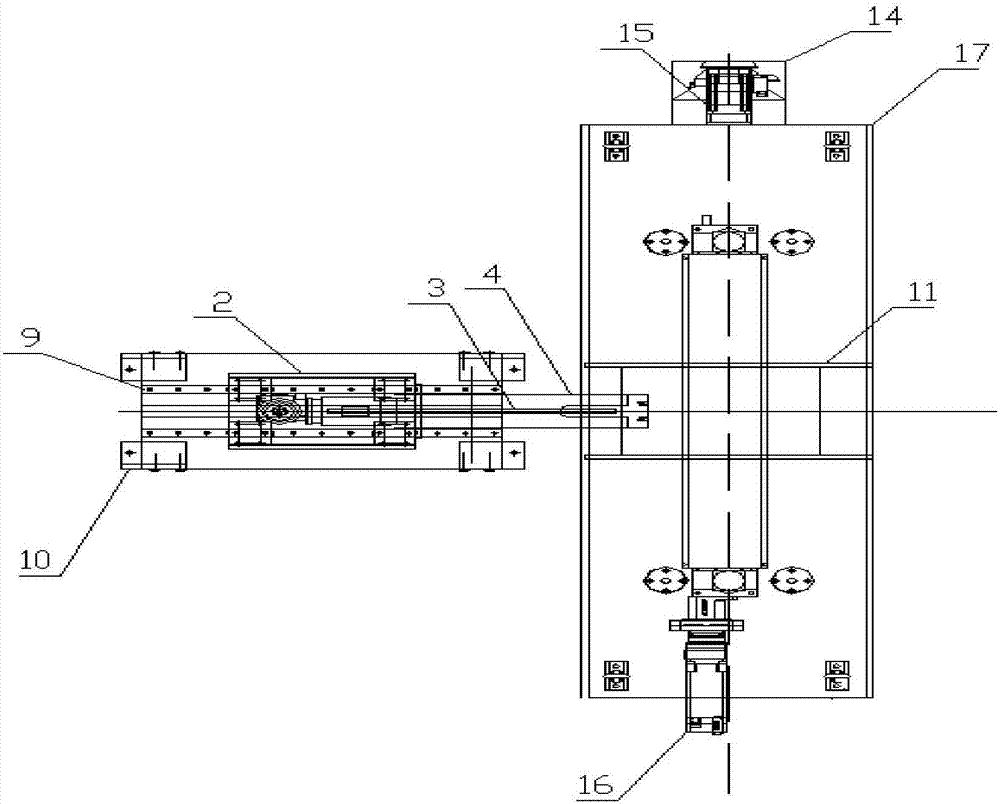

[0030] Specific embodiments: the present invention is a precision wire arrangement device for a wire take-up machine, which is automatically calculated according to the wire take-up speed of the wire take-up machine, the width and thickness of the flat winding wire 1 (hereinafter collectively referred to as the wire) through an external automatic power supply control system, and the wire After the guide wheel is close to the take-up reel, the automatic detection device in the photoelectric switch 5 on the precision wire arrangement device automatically controls the wire arrangement speed of the take-up machine, and detects the two sides of the take-up reel 11 through the photoelectric switch 5, Determine the reversing speed and time and the left and right, front and rear movement of the guide wheel. In normal production, the wire and the wire left and right limit holding device are always kept in a straight line. Inching, the left and right limit holding device 12 of the wire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com