Grommet

A component and hole technology, which is applied to vehicle parts, electrical components, multi-purpose hand tools, etc., can solve problems such as difficulty in installation and force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

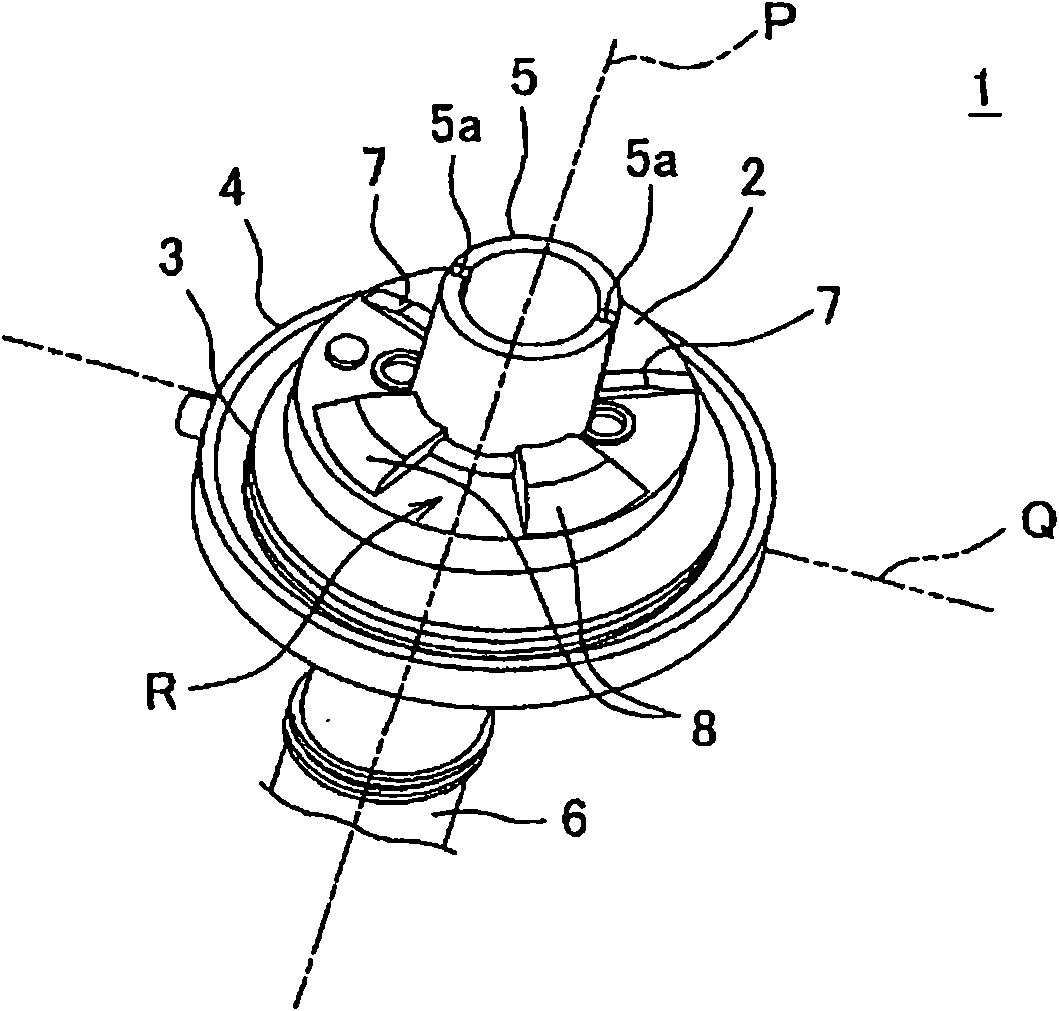

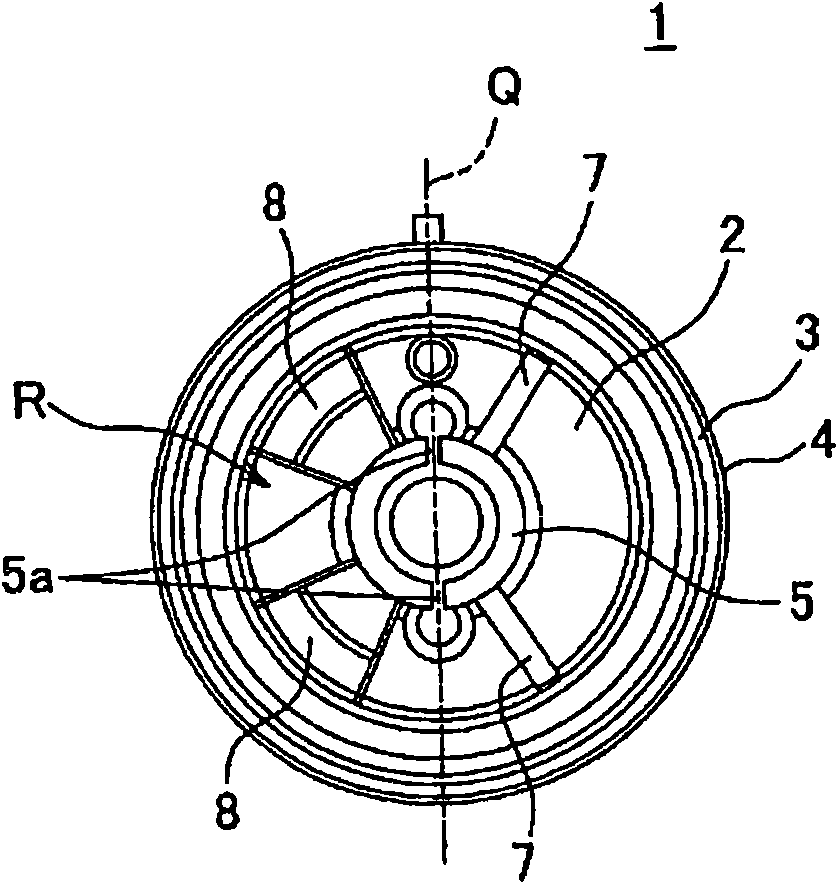

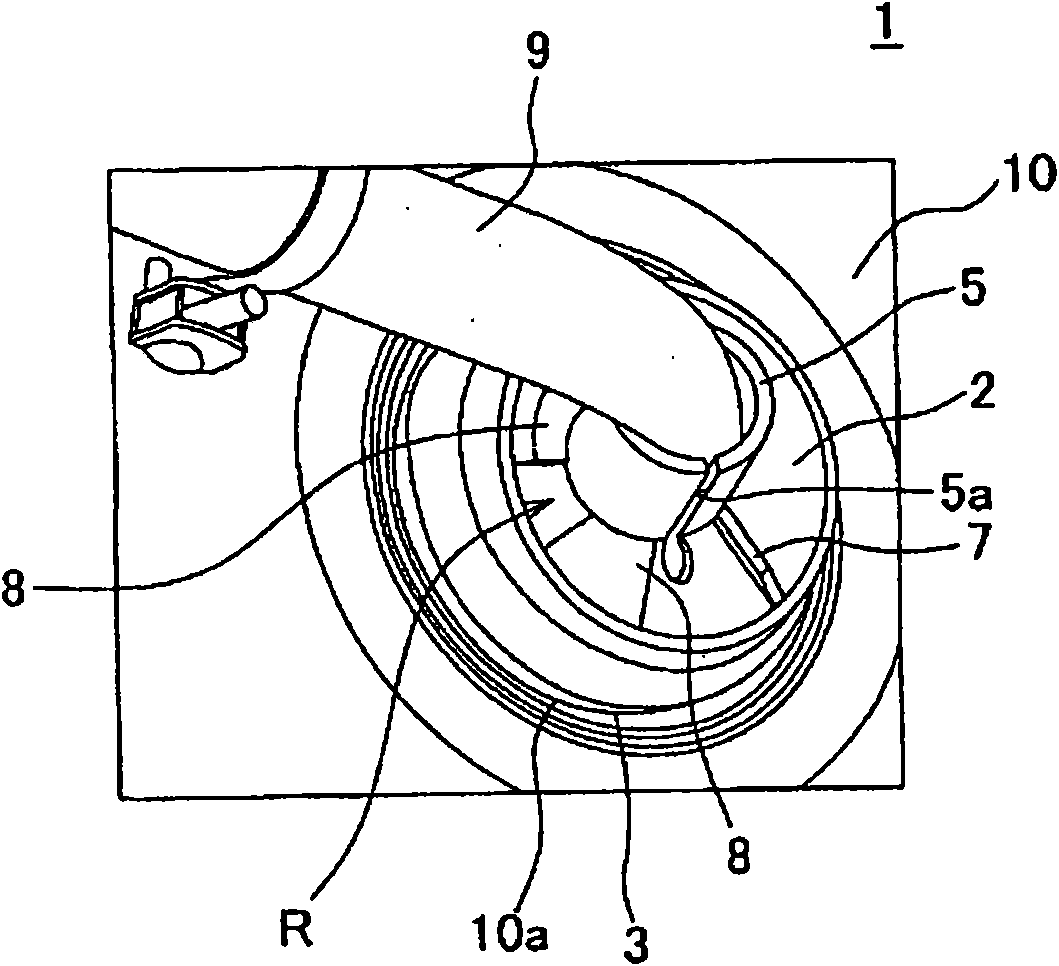

[0032] Below, refer to Figure 1 to Figure 6 An eyelet member according to a first embodiment of the present invention will be described. The eyelet member 1 according to the first embodiment of the present invention is mounted on a vehicle 11 (in Figure 5 In the hole 10a (in the Figure 4 and Figure 5 express). In addition, in this embodiment, the planar shape of the said hole 10a is formed in circular shape.

[0033] The above-mentioned eyelet member 1 is made of freely elastically deformable rubber or the like, and is formed in a cylindrical shape while passing through the wire harness 9 (in the image 3 and Figure 4 express). The eyelet member 1 is watertight with the plate 10 to prevent liquids such as water from infiltrating into the inside from between the plate 10 and to prevent liquids such as water from adhering to the wire harness 9 . Such as Figure 1 to Figure 4 As shown, the eyelet member 1 has a pair of barrel parts 5, 6 and a body part 2 integrally. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com