A construction method of circular reinforced concrete chimney wall inverted formwork

A reinforced concrete and construction method technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of high cost of construction equipment, increased cost of chimneys, and low height, etc., to achieve reduction The overall investment, the construction period is significantly reduced, and the construction labor intensity is moderate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

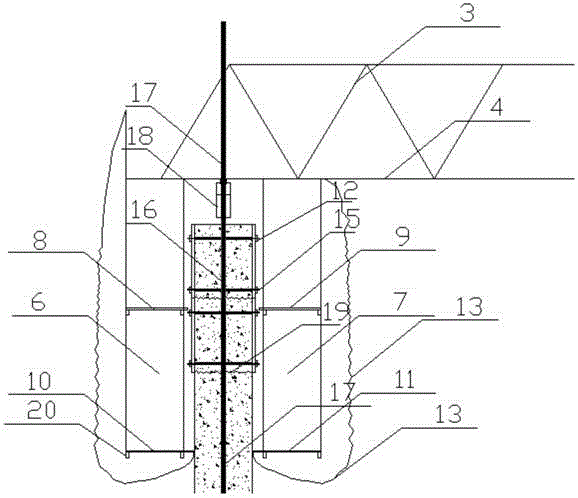

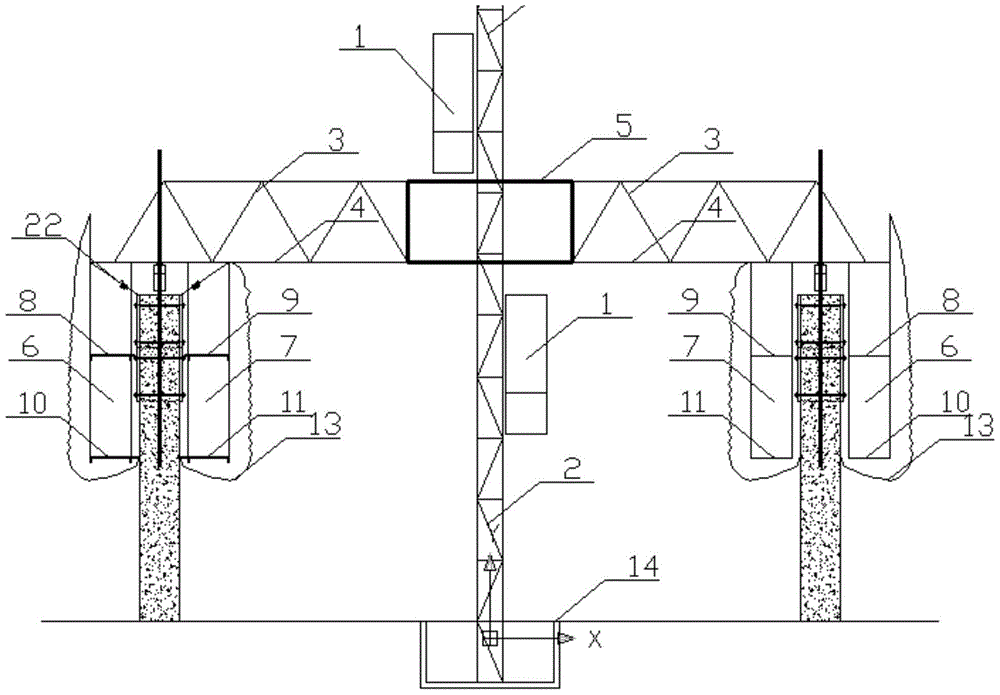

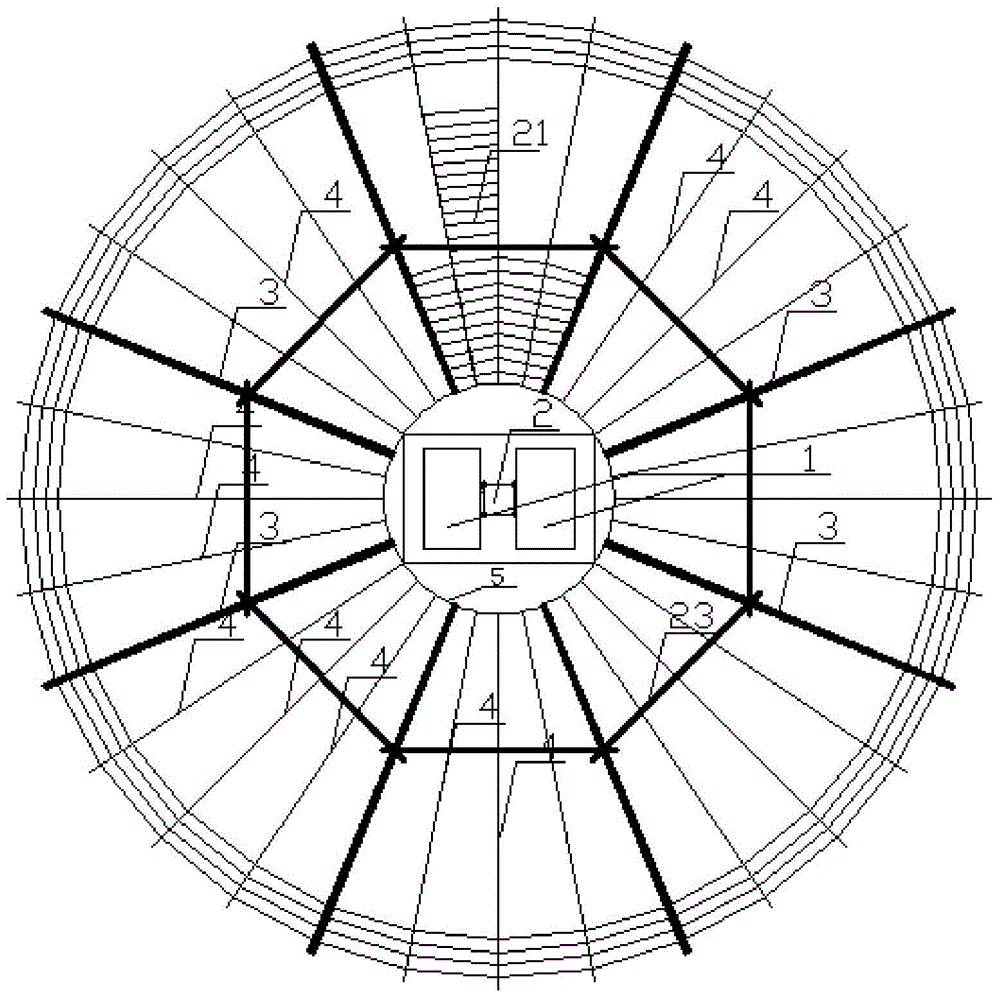

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The invention discloses a method for constructing a circular reinforced concrete chimney wall with an inverted mold. The method comprises the following steps:

[0026] 1) Embed the embedded parts according to the design within the projection range of the top surface of the chimney foundation, conventionally construct the steel bars and formwork of the first section of the chimney wall, install the climbing rod 17, the climbing rod 17 is covered with the climbing rod sheath steel pipe 16, and the climbing rod protection Cover steel pipe 16 outer walls are processed into inverted taper.

[0027] Wherein the climbing rod 17 comprises a main truss climbing rod and a secondary radiation beam climbing rod, the main truss climbing rod is located below the main truss 3, the secondary radiation beam climbing rod is located below the secondary radiation beam 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com