Three-level inverter

A technology of three-level inverters and inductors, which is applied to electrical components, AC power input to DC power output, and output power conversion devices, etc. It can solve problems such as aging damage of switches, unfavorable long-term stable operation of equipment, and bias currents. , to achieve stable performance, conducive to long-term stable operation, and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: The inductor L is connected in series with the current output terminal O.

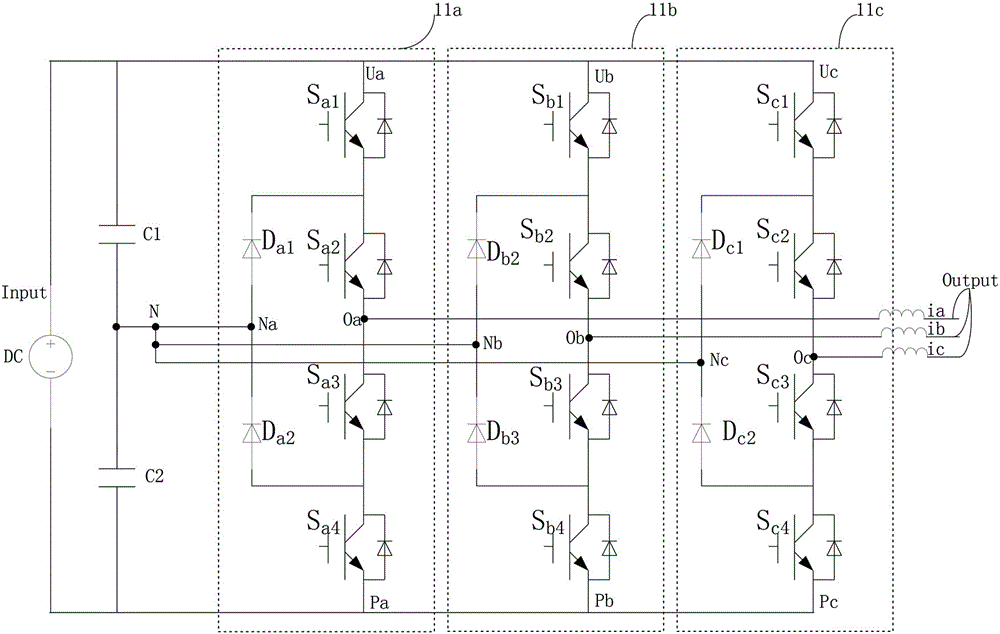

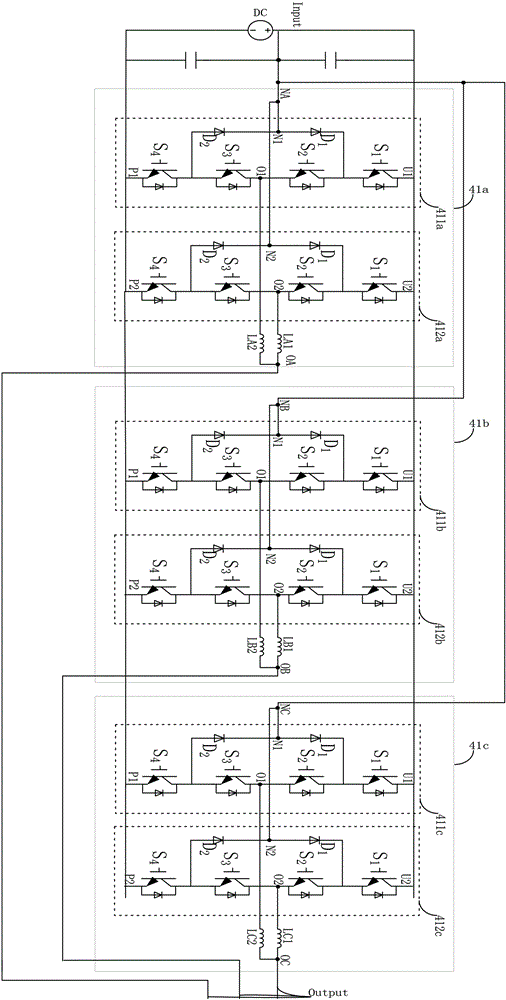

[0015] The three-level inverter in this embodiment includes an A-phase high-power switch 41a, a B-phase high-power switch 41b and a C-phase high-power switch 41c connected in parallel.

[0016] The phase A high-power switch 41a is composed of a phase A first switch module 411a and a phase A second switch module 412a connected in parallel. The B-phase high-power switch 41b is composed of a B-phase first switch module 411b and a B-phase second switch module 412b connected in parallel. The C-phase high-power switch 41c is composed of a C-phase first switch module 411c and a C-phase second switch module 412c connected in parallel.

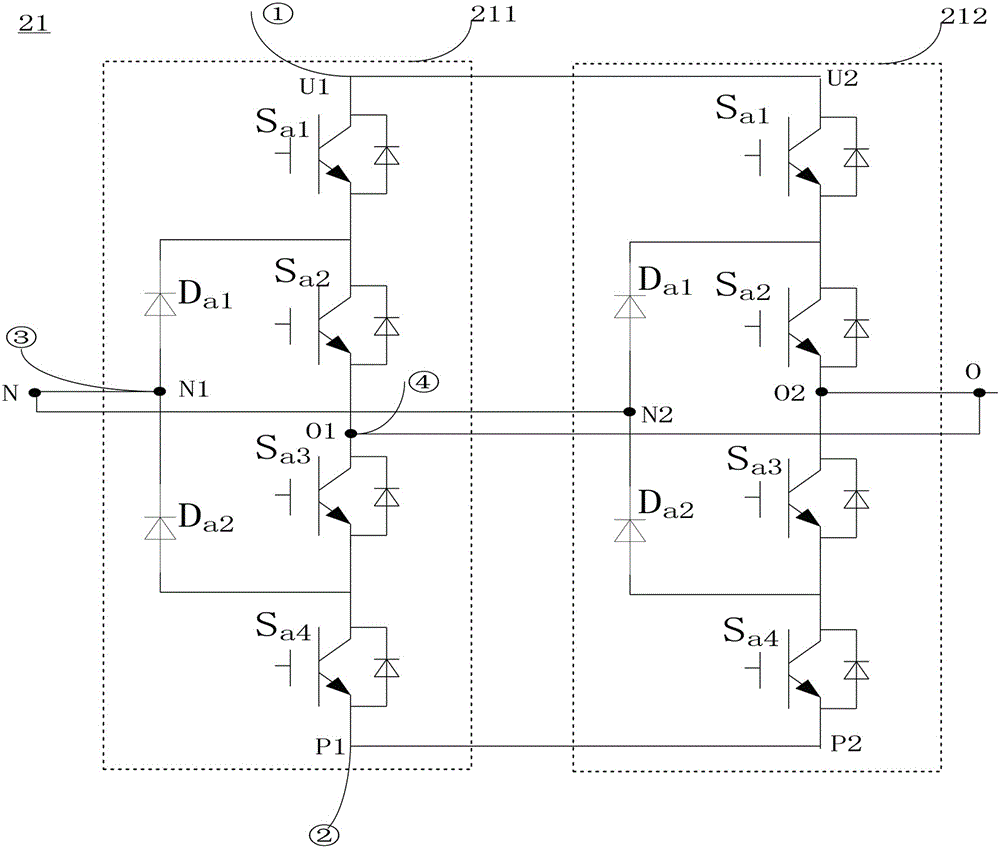

[0017] Each switching module includes IGBT switches S connected in series 1 , IGBT switch S 2 , IGBT switch S 3 and IGBT switch S 4 . Each switch module further includes a diode D1 and a diode D2 connected in series, and the first terminal of the seri...

Embodiment 2

[0020] Embodiment 2, the inductor L is connected in series with the current input terminal N.

[0021] The intermediate terminals of the series branches of the diode D1 and the diode D2 in each switch module are used as current input terminals, each of which is connected in series with an inductor, and then connected to the input terminal of the three-level inverter. The intermediate terminals of the IGBT switch series branches in each switch module are connected to the output terminals of the three-level inverter as current output terminals. Others are the same as embodiment one.

[0022] In the above embodiments, the parameters of the inductors used by the same high-power switch are the same, so as to ensure that the output filter inductor of each phase of the three-level inverter is divided into two inductors, which are respectively arranged in the parallel high-power switch middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com