Large continuous air supply type air-heated vaporizer

An air-temperature vaporizer, a large-scale technology, applied in pressure vessels, heat exchanger types, indirect heat exchangers, etc. The effect of controlling stress compensation, strong overall rigidity and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

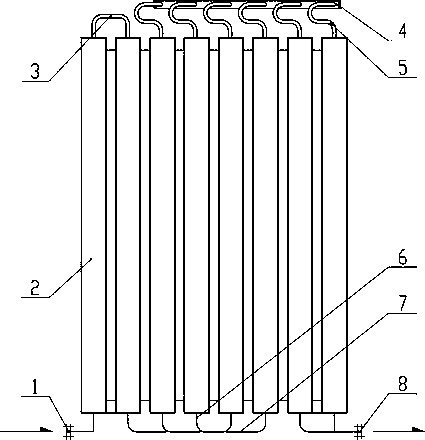

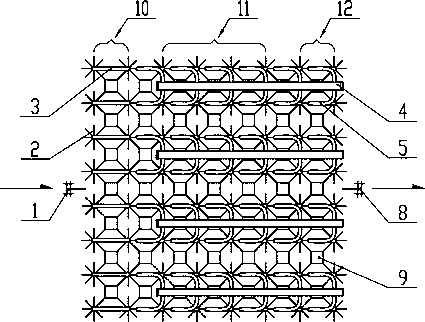

[0015] figure 1 , figure 2 Including liquid inlet 1, heat exchange fin tube 2, first connecting pipe 3, first connecting pipe 4, second connecting pipe 5, third connecting pipe 6, second connecting pipe 7, air outlet 8, connecting Part 9, subcooling section 10, evaporation section 11, heating section 12, etc.

[0016] Such as figure 1 , figure 2 As shown, the present invention is a large-scale air-temperature gasifier with continuous air supply type 0.... In the embodiment, it is a matrix with 8 rows and 8 columns.

[0017] The heat exchange fin tube bundle is divided into parallel subcooling section 10, evaporating section 11 and heating section 12 from the liquid inlet 1 to the gas outlet 8, and the subcooling section 10, evaporating section 11 and heating section 12 are connected in series between the liquid inlet 1 and the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com