Water spraying and cooling system for bearing test of free high-temperature compression member

A compression component, water spray cooling technology, applied in the field of structural engineering and fire science, can solve the problems of poor cooling effect of high temperature test components, unable to meet technical requirements, waste of water resources, etc., and achieve good cooling effect consistency and cooling effect. Good, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

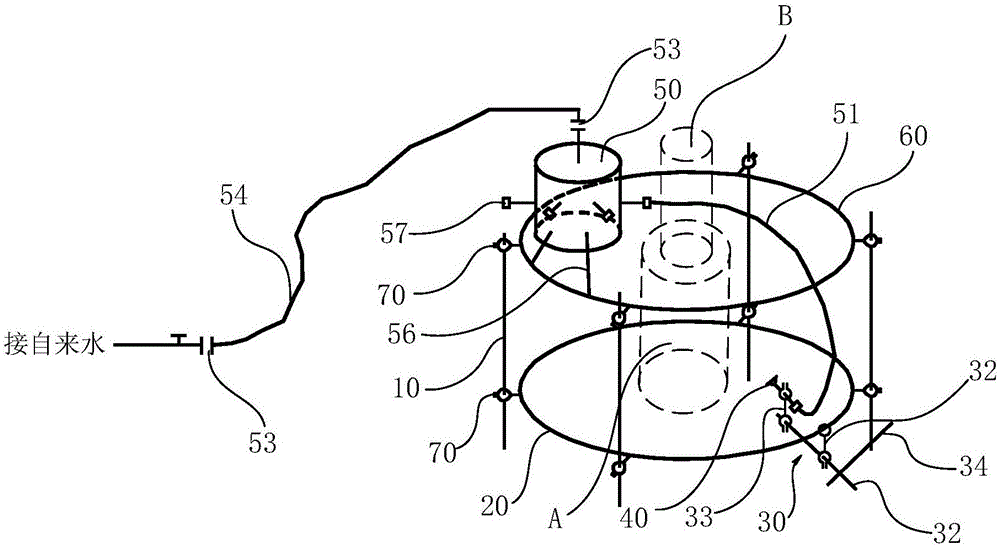

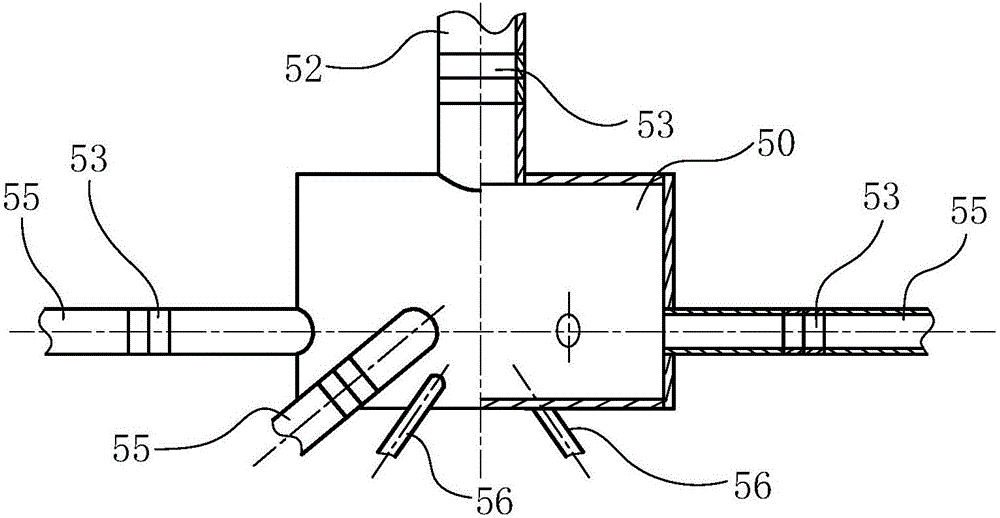

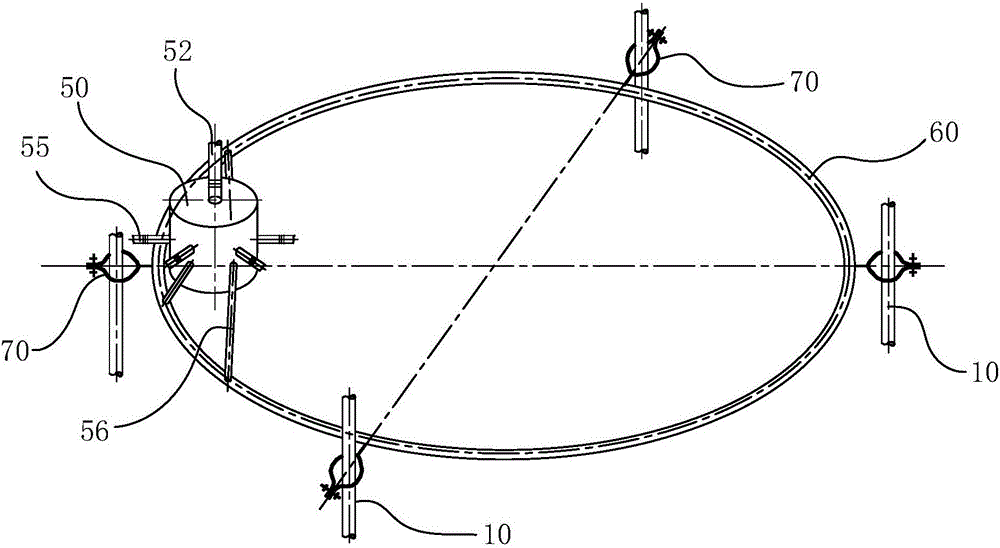

[0026] combine Figure 1 to Figure 8 , the present invention is further described:

[0027] The free-style high-temperature pressure member bearing test water spray cooling system includes a metal bracket 10 arranged around the pressure member A, and the metal bracket 10 is provided with a lower fastening ring 20, and the pressure member A is arranged on the lower fastening circle. At the center position of the ring 20, the annular surface of the lower fastening ring 20 is horizontal and spaced with a plurality of free rocker arm assemblies 30, and the overhanging end of the free rocker arm assembly 30 is provided with a cooling water nozzle 40, the cooling water The distance between the nozzle 40 and the pressure member A is adjustable, and the spraying direction of the cooling water nozzle 40 points to the center of the annulus of the lower fastening ring 20 and is obliquely upward.

[0028] combine figure 1 As shown, the load applying rod B exerts pressure on the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com