Blow tank odor treatment system and treatment method

A technology of odor and pot odor, which is applied in the field of pollution control, can solve problems such as odor pollution and exhaustion, and achieve the effects of saving investment costs, stabilizing temperature and gas volume, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

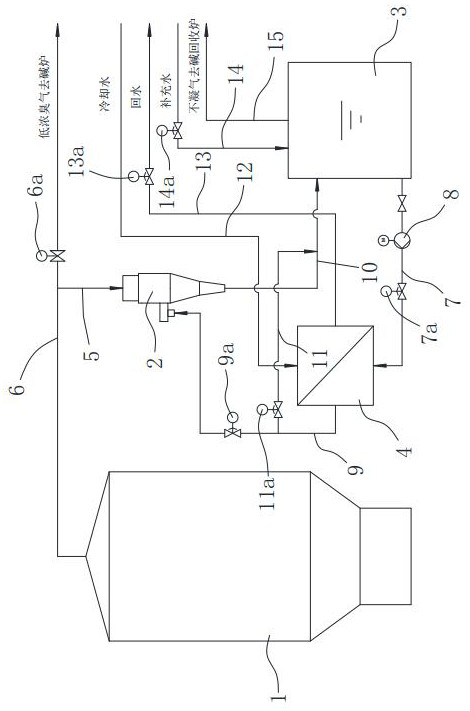

[0034] Such as figure 1 As shown, the application embodiment of the present invention provides a spray pot odor control system, including a spray pot 1, a condensation injector 2, a sewage hot water tank 3, a heat exchanger 4, and the like.

[0035] The outlet on the spray pot 1 top is connected with an alkali furnace through a low-concentration odor pipe 6, and the low-concentration odor pipe 6 is provided with a bypass valve 6a.

[0036] The upper end of the condensing ejector 2 has an air inlet, and the low-concentration odor pipe 6 between the spray pot 1 and the bypass valve 6a is connected to the air inlet on the upper end of the condensing ejector 2 through the first pipeline 5 .

[0037] The outlet of the sewage hot water tank 3 is connected to the inlet of the heat exchanger 4 through the second pipeline 7 , and the outlet of the heat exchanger 4 is connected to the water inlet of the condensation injector 2 through the third pipeline 9 .

[0038] A jet pump 8 and a ...

Embodiment 2

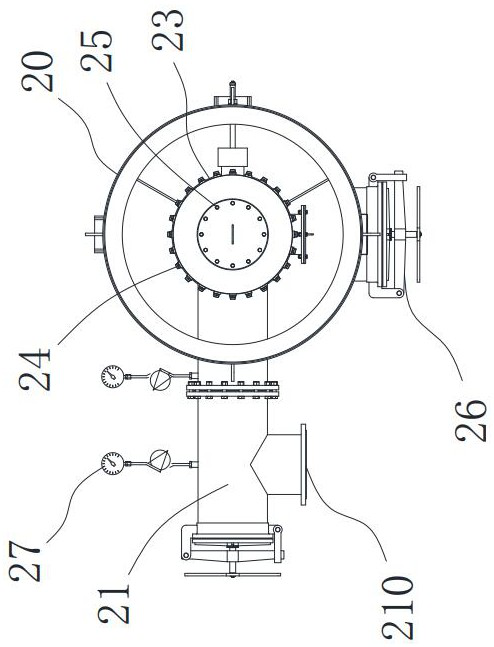

[0043] Existing ZJF jet condenser (such as Figure 4 As shown), the orifice plate 100 on the top is prone to fouling and blockage, resulting in a drop in the pressure of the condensed water and a decrease in the odor absorption capacity, which eventually leads to the direct discharge of the odor and pollutes the air.

[0044] Such as Figure 1 ~ Figure 3 As shown, the application embodiment of the present invention provides a spray pot odor control system, including a spray pot 1, a condensation injector 2, a sewage hot water tank 3, a heat exchanger 4, and the like.

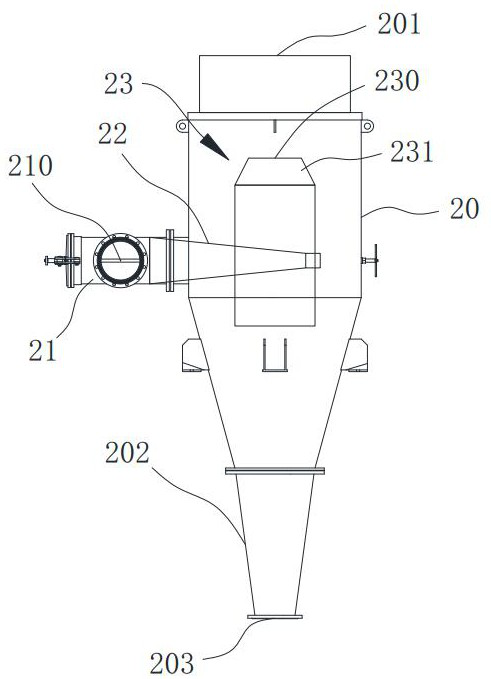

[0045] The outlet on the spray pot 1 top is connected with an alkali furnace through a low-concentration odor pipe 6, and the low-concentration odor pipe 6 is provided with a bypass valve 6a. The upper end of the condensing injector 2 has an air inlet 201, and the low-concentration odor pipe 6 between the spray pot 1 and the bypass valve 6a is connected to the air inlet 201 at the upper end of the condensing in...

Embodiment 3

[0054] Such as Figure 1 ~ Figure 3 As shown, the embodiment of the application of the present invention provides a method for controlling the odor of the spray pot, which is carried out by using the system described in Embodiment 1 and / or Embodiment 2, including the following steps:

[0055] In step S1, before the coarse slurry enters the spray pot 1, water is supplied to the condensing injector 2 for a certain time in advance, so that a slight negative pressure is established in the exhaust pipe.

[0056] When the cooking pot enters the discharge program, the DCS system automatically starts the jet pump 8 60 seconds in advance, opens the second control valve 9a, closes the third control valve 11a to supply water to the condensing jet 2, and the jet water passes through the heat exchanger 4 to exchange heat with The pressure greater than or equal to 0.05MPa supplies water to the condensing injector 2, so that the exhaust pipe establishes a slight negative pressure. The verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com