Manufacture method of ultrathin single-fiber polyamide drawn textured yarn (6DTY)

A fine single-fiber nylon and manufacturing method technology, applied in the field of spinning, can solve the problems of unstable product quality, limited production capacity and application prospects, prone to broken ends, wool, etc., to reduce broken ends and DTY wool The effect of silk, ultra-fine single fiber with small fineness and good DTY physical index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

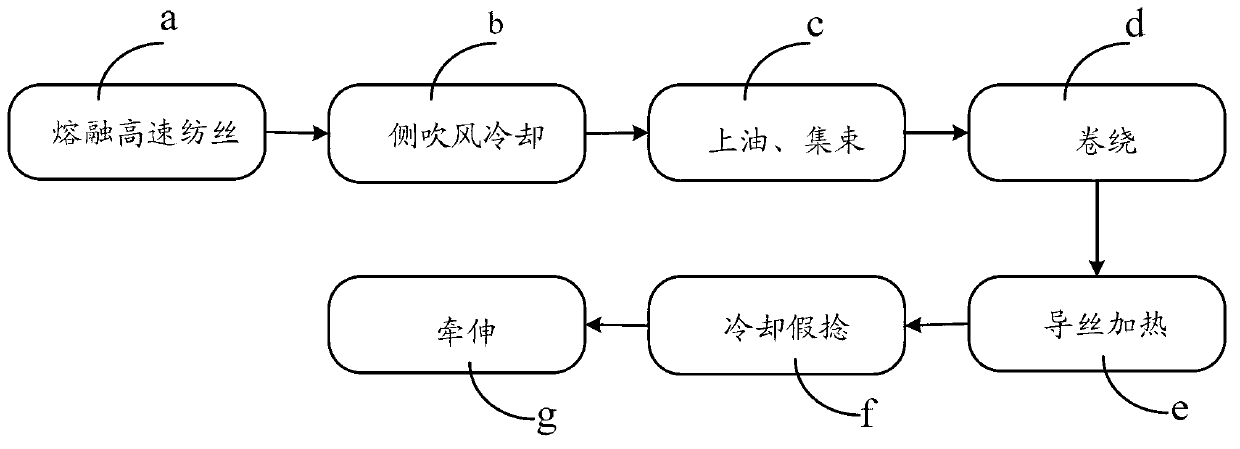

[0047] A kind of manufacture method of superfine single fiber nylon 6DTY, comprises the following steps:

[0048] a) Melt high-speed spinning: Nylon 6 chips are melted and high-speed spinning, wherein the screw pressure is 110kg / cm 2 , the screw speed is 30r / min, the melt spinning temperature is 255°C, the spinneret holes used are circular, the diameter is 0.15mm, and the aspect ratio is 3.0;

[0049] b) Side blowing cooling: wind temperature 17°C, humidity 90%, wind speed 0.3m / s;

[0050] c) Oiling and clustering: the fibers cooled by side blowing are oiled and clustered through the oil mist nozzle. The oil used is 6% nylon oil pure water emulsion, and the oiling rate is 0.6%;

[0051] d) Winding: the oiled tow passes through the pre-netting device, the godet, and the main network device, and starts winding and spinning at a spinning speed of 4000m / min to obtain POY filaments;

[0052] e) Guide wire heating: the POY filament passes through the guide wire, wire feeding rolle...

Embodiment 2

[0057] A kind of manufacture method of superfine single fiber nylon 6DTY, comprises the following steps:

[0058] a) Melt high-speed spinning: Nylon 6 slices are melted and high-speed spinning, wherein the screw pressure is 115kg / cm 2 , the screw speed is 45r / min, the melt spinning temperature is 263°C, the spinneret holes used are circular, the diameter is 0.25mm, and the aspect ratio is 2.5;

[0059] b) Side blowing cooling: wind temperature 18°C, humidity 95%, wind speed 0.4m / s;

[0060] c) Oiling and clustering: the fibers cooled by side blowing are oiled and clustered through the oil mist nozzle. The oil used is 8% nylon oil pure water emulsion, and the oiling rate is 0.7%;

[0061] d) Winding: the oiled tow passes through the pre-netting device, the godet, and the main network device, and starts winding and spinning at a spinning speed of 4100m / min to obtain POY filaments;

[0062] e) Guide wire heating: the POY filament passes through the guide wire, wire feeding roll...

Embodiment 3

[0067] A kind of manufacture method of superfine single fiber nylon 6DTY is characterized in that, comprises the following steps:

[0068] a) Melt high-speed spinning: Nylon 6 chips are melted and high-speed spun, wherein the screw pressure is 112kg / cm2, the screw speed is 40r / min, the melt spinning temperature is 260°C, and the spinneret holes used are circular, with a diameter of 0.20mm, aspect ratio 2.5;

[0069] b) Side blowing cooling: wind temperature 17°C, humidity 92%, wind speed 0.35m / s;

[0070] c) Oiling and clustering: the fibers cooled by side blowing are oiled and clustered through the oil mist nozzle. The oil used is 7% nylon oil pure water emulsion, and the oiling rate is 0.65%;

[0071] d) Winding: the oiled tow passes through the pre-netting device, the godet, and the main network device, and starts winding and spinning at a spinning speed of 4050m / min to obtain POY filaments;

[0072] e) Guide wire heating: the POY filament passes through the guide wire, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com