Method for producing ptzt piezoelectric film and liquid composition for forming piezoelectric film thereof

Technology of a liquid composition, manufacturing method, application in manufacture/assembly of piezoelectric/electrostrictive devices, selection of materials for piezoelectric or electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices Orientation can solve the problems of unreported piezoelectric film evaluation results, etc., and achieve the effects of long average breakdown time, suppression of precipitation, and high degree of crystal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1) Preparation process of the first synthetic solution

[0031] In the step of preparing the first synthetic liquid, the Ta alkoxide, Zr alkoxide, β-diketone, and diol are refluxed to react the Ta alkoxide and Zr alkoxide with the diol, thereby preparing the first synthetic liquid. Specifically, Ta alkoxide and Zr alkoxide were weighed so that the ratio of the predetermined metal atomic ratio in the film-formed PTZT piezoelectric film was given. The weighed Ta alkoxide and Zr alkoxide are put into a reaction vessel together with β-diketones and diols, mixed, and preferably refluxed at a temperature of 130-175° C. for 0.5-3 hours in a nitrogen atmosphere to prepare a synthesis liquid.

[0032] As the Ta alkoxide, alkoxides such as tantalum ethoxide may, for example, be mentioned. This tantalum ethoxide is preferable because it is easily available, but it is highly reactive and tends to generate precipitates. Therefore, in the preparation step of the first synthetic so...

Embodiment

[0054] Next, examples of the present invention will be described in detail together with comparative examples.

[0055]

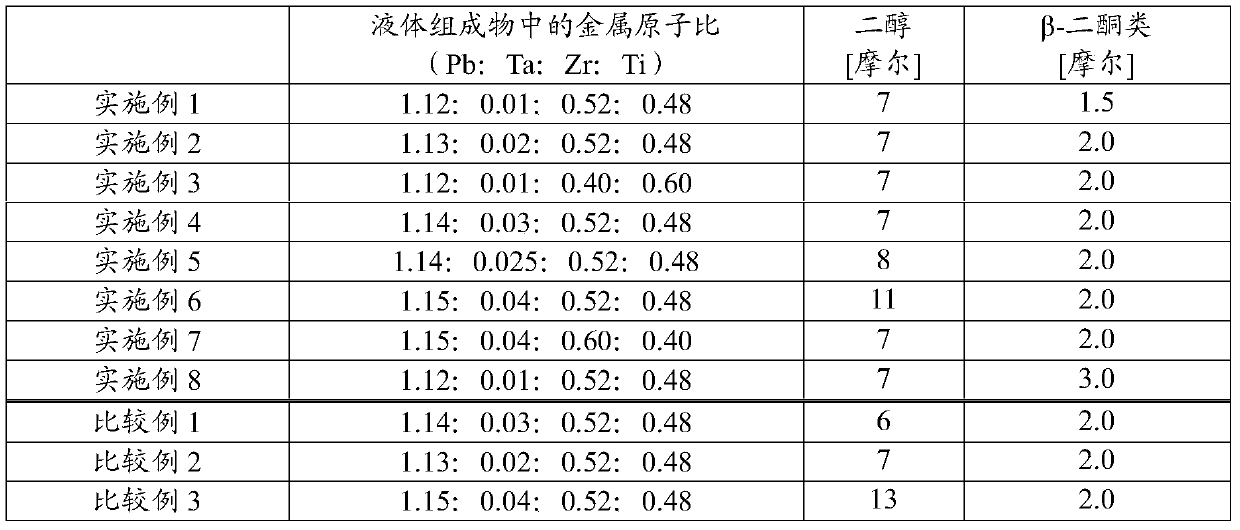

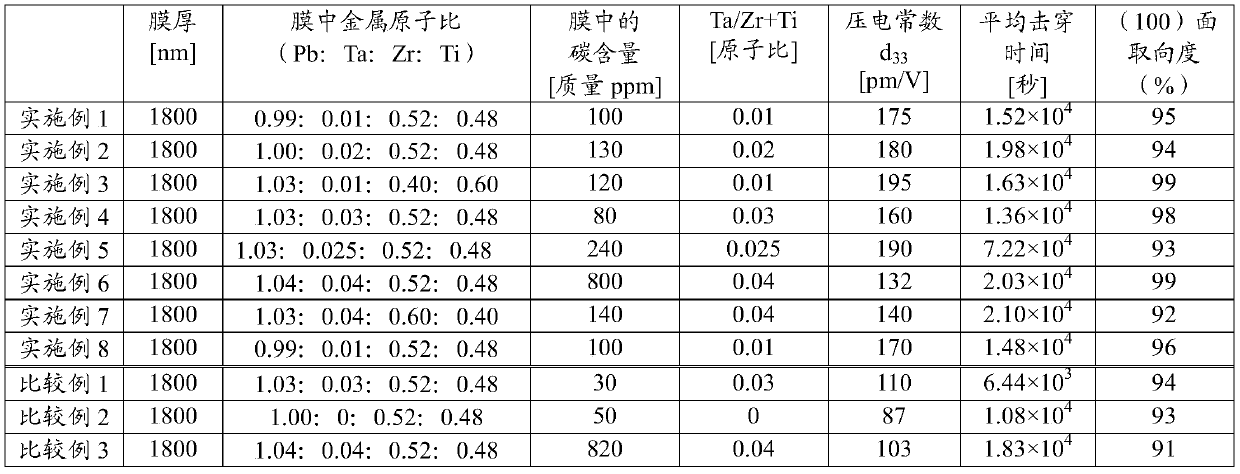

[0056] First, zirconium n-butoxide (Zr source), tantalum ethoxide (Ta source), acetylacetone (β-diketones), and propylene glycol (diol) were put into a reaction vessel and mixed. This mixed solution was refluxed at a temperature of 150° C. for 0.5 hours in a nitrogen atmosphere to prepare a synthetic solution. Titanium tetraisopropoxide (Ti source) and acetylacetone were added to the obtained synthesis liquid, and it refluxed again at the temperature of 150 degreeC for 0.5 hour, and cooled to room temperature. Lead acetate trihydrate (Pb source) was added to the obtained synthesis liquid, and it refluxed at the temperature of 150 degreeC for 1 hour further. The concentration of the PTZT precursor contained in 100% by mass of the synthesis liquid obtained by adding lead acetate trihydrate was distilled under reduced pressure to remove unnecessary solvents...

Embodiment 2~8

[0059] The liquid compositions for forming PTZT piezoelectric films of Examples 2 to 8 were prepared in the same manner as in Example 1, except that the mix of raw materials was changed to the following Table 1, and Examples 2 to 8 were obtained in the same manner as in Example 1. 8 PTZT piezoelectric film.

[0060]

[0061] When the total amount of zirconium n-butoxide, tantalum ethoxide, and titanium tetraisopropoxide was 1 mol, propylene glycol (diol) was contained in the liquid composition in a ratio of 6 mol to the total amount. Except for this, the liquid composition for PTZT piezoelectric film formation was prepared similarly to Example 4. 1000 μL of the liquid composition for forming a PTZT piezoelectric film was dropped on the uppermost PZT film (orientation control film) of the silicon substrate of the same 4-inch size as in Example 1 set on a spin coater. Spin coating was performed in the same manner. After the spin coating, the PTZT precursor film (gel film) as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com