Preparation method of waterproof shell fabric

A technology for waterproof fabrics and sizing materials, which is used in manufacturing tools, textiles and papermaking, and fiber processing. The effect of breaking strength and reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

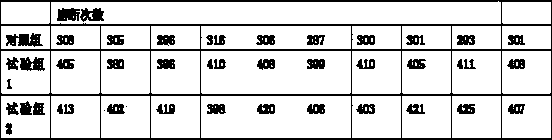

Examples

Embodiment 1

[0034] A kind of preparation method of waterproof fabric, adopts the nylon of 20D / 12F, comprises the following steps:

[0035] 1. Raw silk inspection

[0036] 2. Warp yarn treatment: including the steps of hanging yarn, warping, sizing, doubling, splitting, drawing in heald and reeding.

[0037] Warping: The warp yarns are drawn out from the creel at the same time, and wound on the warp beam in parallel to form a warp beam. The humidity in the workshop is controlled at 55%, the speed of the machine is 250m / min, and the tension of the yarn is controlled at a total tension of 8.9kg / single yarn The tension is 5.6g, and the hairiness sensitivity is 3.3;

[0038] Sizing: combine the warp beams, sizing and pressing, and wind them into weaving beams after being dried in a drying room. , ethanol 3%, water 76%, the slurry temperature is 44°C, the sizing rate during sizing is 10.5%, the vehicle speed is 250m / min, and the dipping roller pressure (dipping the warp yarn into the slurry) ...

Embodiment 2

[0046] A preparation method of a waterproof fabric, comprising the following steps:

[0047] 1. Raw silk inspection

[0048] 2. Warp yarn treatment: including the steps of hanging yarn, warping, sizing, doubling, splitting, drawing in heald and reeding.

[0049] Warping: The warp yarns are drawn out from the single creel at the same time, and wound on the warp beam in parallel to form a warp beam. The humidity in the workshop is controlled at 65%, the speed of the vehicle is 270m / min, and the tension of the yarn is controlled at a total tension of 9.1kg. Hairiness sensitivity is 3.5;

[0050] Sizing: combine the warp beams, sizing and pressing, and wind them into weaving beams after being dried in the drying room. , ethanol 4%, water 74%, the slurry temperature is 48°C, the sizing rate is 11.5%, the vehicle speed is 270m / min, and the dipping roller pressure is 3.7kg / cm 2 , the pressure of the pressure roller is 3.5kg / cm when grouting 2 , the drying temperature is 140°C; ...

Embodiment 3

[0058] A preparation method of a waterproof fabric, comprising the following steps:

[0059] 1. Raw silk inspection

[0060] 2. Warp yarn treatment: including the steps of hanging yarn, warping, sizing, doubling, splitting, drawing in heald and reeding.

[0061] Warping: Draw the warp yarns from the single creel at the same time, and wind them in parallel on the warp beam to form a warp beam. The humidity in the workshop is controlled at 60%, the speed of the machine is 260m / min, and the tension of the yarn is controlled at a total tension of 9kg. The sensitivity is 3.5;

[0062] Sizing: combine warp beams, sizing and pressing, and wind them into weaving beams after being dried in a drying room. The size used for sizing consists of 19% (by weight) of acrylate polymer and 3.5% of emulsified paraffin , ethanol 3.5%, water 74%, the slurry temperature is 47°C, the sizing rate during sizing is 115%, the vehicle speed is 260m / min, the dipping roller pressure (dipping the warp yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com