Three-point mutual wrapping and winding type spun yarn evening and ordering device and method

A wrapping and spun yarn technology, which is applied in the field of spinning, can solve problems such as small short-term profit margins, increased energy consumption costs, and large power consumption, and achieves the improvement of thick places and uneven details, the reduction of end-breakage rates, and the acceleration Effect of Twist Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

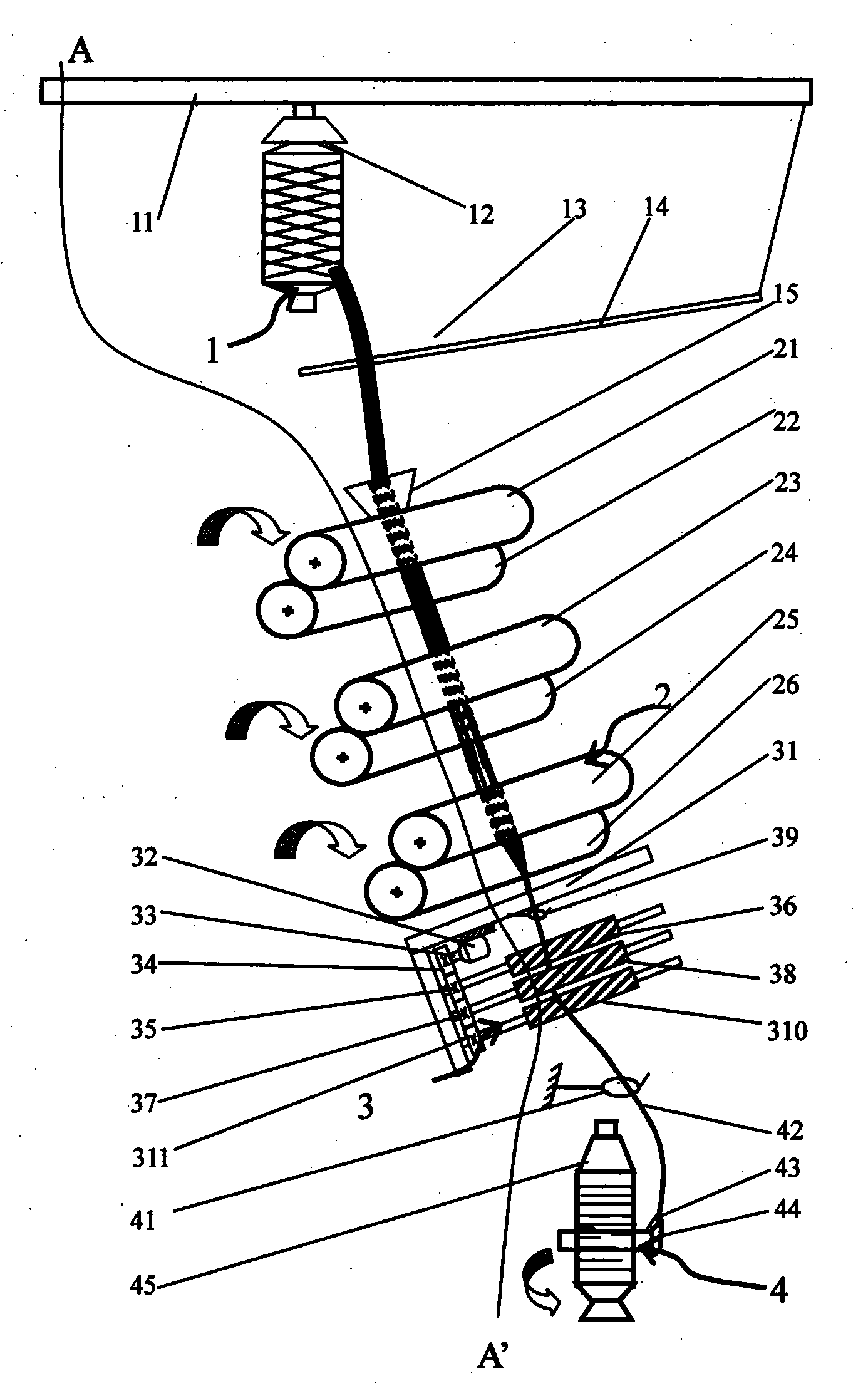

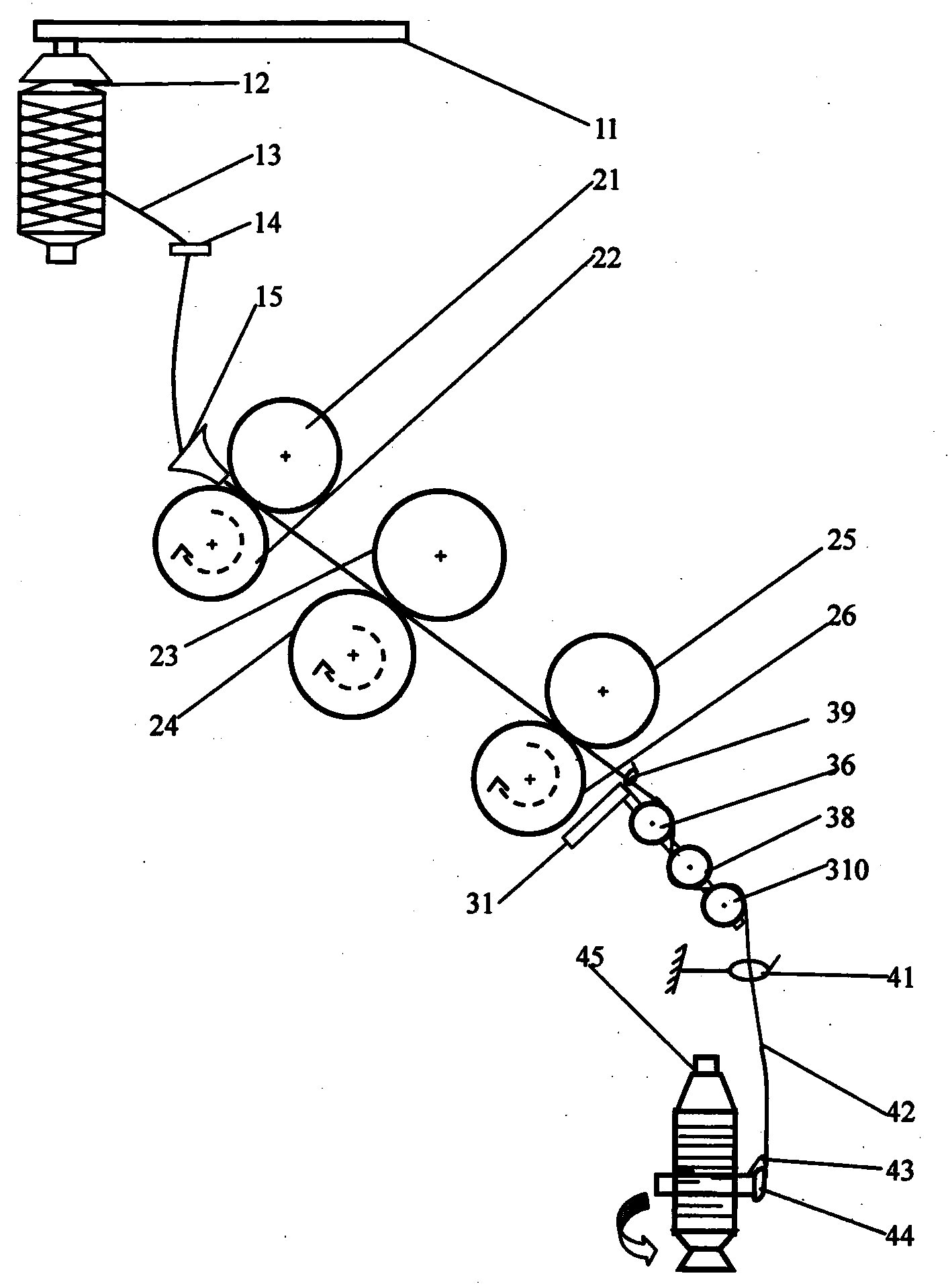

[0036] Such as figure 1 As shown, it is the front view of the three-point alternating wrapping spun leveling device. The three-point alternating wrapping spun leveling device includes a roving supply mechanism 1, a drafting mechanism 2, a twisting and winding mechanism 4 and three points The alternate wrapping mechanism 3; the roving supply mechanism 1 is composed of an upper beam 11, a roving bobbin 12, a roving 13, a yarn guide rod 14 and a cluster horn 15; the roving bobbin 12 can be suspended on the upper beam 11, and the roving 13 is drawn to the nip of the rear upper roller 21 and the rear lower roller 22 of the drafting mechanism 2 via the yarn guide rod 14 and the cluster horn 15; figure 2 Shown, described drafting mechanism 2 is made of rear upper roller 21, rear lower roller 22, middle upper roller 23, middle lower roller 24, front upper roller 25 and front lower roller 26, by a pair of rear upper roller 21 and The rear bottom roller 22 and a pair of middle top rol...

Embodiment 2

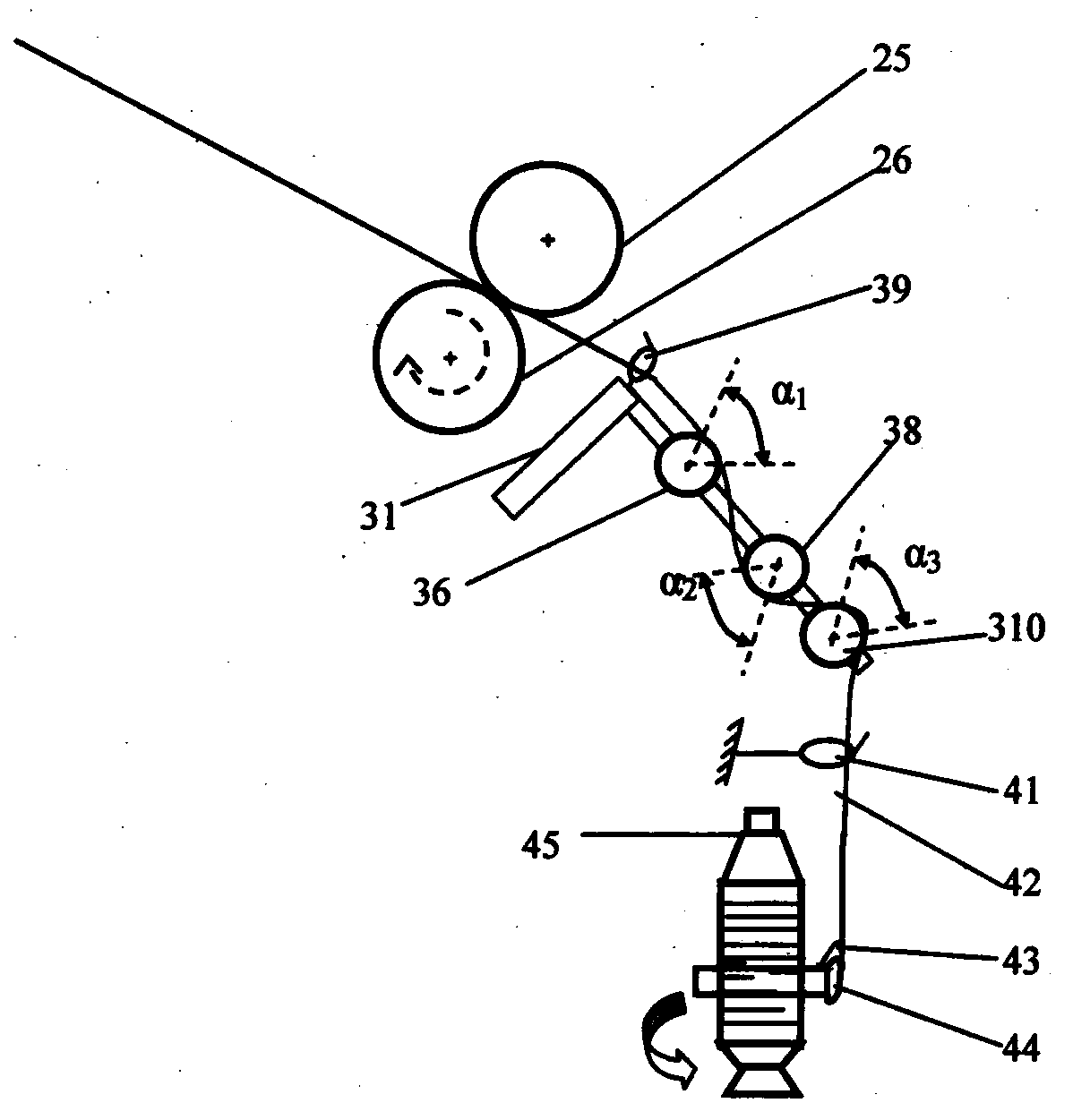

[0042] A three-point alternating wrapping spun yarn leveling device, similar to Embodiment 1, the difference is that the outer diameters of the first wrapping roller 36, the second wrapping roller 38 and the third wrapping roller 310, the first wrapping roller 36. The rotation speed of the second wrapping roller 38 and the third wrapping roller 310, the wrapping angle α between the first wrapping roller 36 and the spun yarn 42 1 , the wrapping angle α between the second wrapping roller 38 and the spun yarn 42 2 , the wrapping angle α between the third wrapping roller 310 and the spun yarn 42 3 sum (eg image 3 shown), the angle θ between the wrapping texture 361 and the corresponding centerline of the wrapping roller axis (such as Figure 4 shown), the logarithm value of the surface roughness of the wrapping texture 361, the coefficient of variation of the logarithmic value of the roughness, the material of the wrapping texture 361, the surface friction coefficient of the wr...

Embodiment 3

[0048] A three-point alternating wrapping spun yarn leveling device, similar to Embodiment 1, the difference is that the outer diameters of the first wrapping roller 36, the second wrapping roller 38 and the third wrapping roller 310, the first wrapping roller 36. The rotation speed of the second wrapping roller 38 and the third wrapping roller 310, the wrapping angle α between the first wrapping roller 36 and the spun yarn 42 1 , the wrapping angle α between the second wrapping roller 38 and the spun yarn 42 2 , the wrapping angle α between the third wrapping roller 310 and the spun yarn 42 3 sum (eg image 3 shown), the angle θ between the wrapping texture 361 and the corresponding centerline of the wrapping roller axis (such as Figure 4 shown), the logarithm value of the surface roughness of the wrapping texture 361, the coefficient of variation of the logarithmic value of the roughness, the material of the wrapping texture 361, the surface friction coefficient of the wr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com