Special polyester filaments for black fine denier industry, and preparation method of special polyester filament

An industrial, black technology, applied in rayon manufacturing, filament forming treatment, single-component polyester rayon, etc., can solve the problems of high breakage rate, long process flow, uneven distribution, etc., and achieve economical The effect of production cost, avoidance of environmental pollution and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention provides a kind of black fine denier industrial polyester special filament, comprising: super glossy polyester and black color masterbatch, wherein the mass fraction of the black color masterbatch in the super glossy polyester is 3-4 %, the black color masterbatch includes the following materials: 30-50% polyethylene terephthalate, 30-50% polybutylene terephthalate, 10-30% carbon Black and 0.4-12% of auxiliary additives.

[0020] Optionally, the auxiliary additives include: 0.1-3% heat stabilizer, 0.1-3% antioxidant, 0.1-5% dispersant, and 0.1-1% coupling agent.

[0021] Optionally, the heat stabilizer is one or more of the following: stearates, organotin mercaptans, and dibutyltin laurate.

[0022] Optionally, the antioxidant is one or more of the following: 1010, 1330, 168, MARK5118A.

[0023] Optionally, the dispersant is one or more of the following: polyethylene wax, CH series; the coupling agent is titanate.

[0024] In the present invention, by a...

Embodiment 2

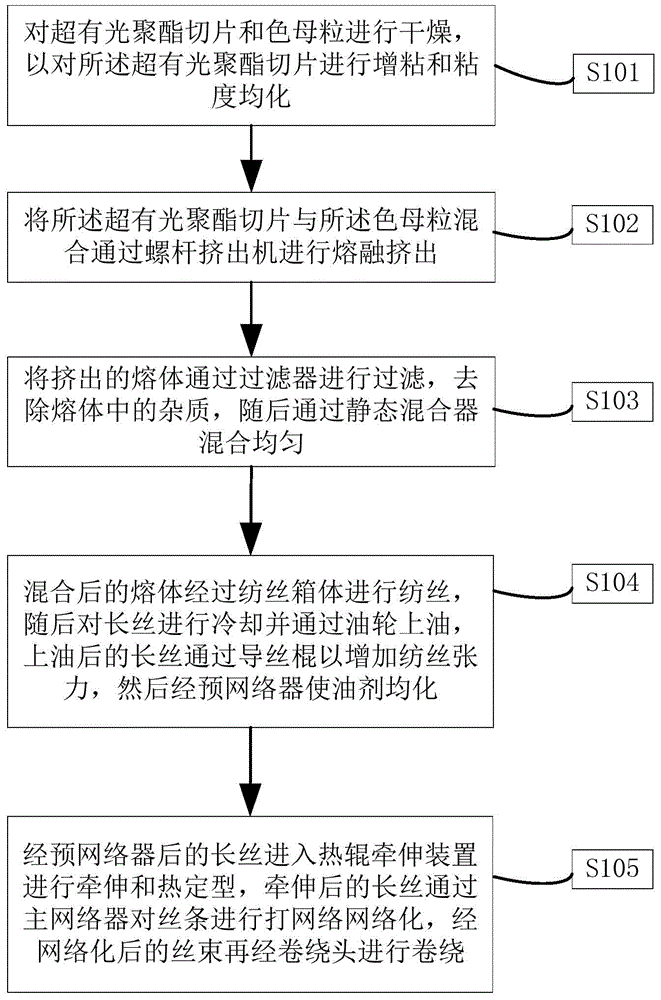

[0026] like figure 1 As shown, the present invention also provides a method for preparing black fine denier industrial polyester special filament, comprising steps:

[0027] S101: drying the super-bright polyester chips and the black masterbatch, so as to increase the viscosity and homogenize the viscosity of the super-bright polyester chips;

[0028] S102: mixing the super-bright polyester chips and the black masterbatch through a screw extruder for melt extrusion;

[0029] S103: Filter the extruded melt through a filter to remove impurities in the melt, and then mix it uniformly with a static mixer;

[0030] S104: The mixed melt is spun through the spinning box, and then the filament is cooled and oiled by the oil tanker. The oiled filament passes through the guide rod to increase the spinning tension, and then passes through the pre-netting device. oil homogenization;

[0031] S105: The filament after the pre-netting device enters the drafting device for drafting and hea...

Embodiment 3

[0039]Wet polyester chips are removed by vibrating sieves to remove powder and large particles, and then transported to the fluidized bed pre-crystallizer by a pulse device, staying in the pre-crystallizer for 15-20min, drying temperature 185°C, staying in the main drying tower for 6h, drying temperature 168°C, so that the moisture content of the slices after drying is ≤20ppm; and then distributed to each dry slice storage tank for later use.

[0040] It chooses A color masterbatch and dry super-bright polyester chips to be fed into a single-screw extruder at the same time for melt extrusion, wherein the characteristics of A color masterbatch are: the high-viscosity polyester chips (1.05- 1.15dL / g) content is 36.50%, polybutylene terephthalate content is 36.1%, carbon black content is 23%, heat stabilizer 0.15%, antioxidant 0.15%, dispersant 4.0%, coupling agent 0.1%; the addition ratio of color masterbatch and super bright polyester chips is 100:3.5.

[0041] Select A color ...

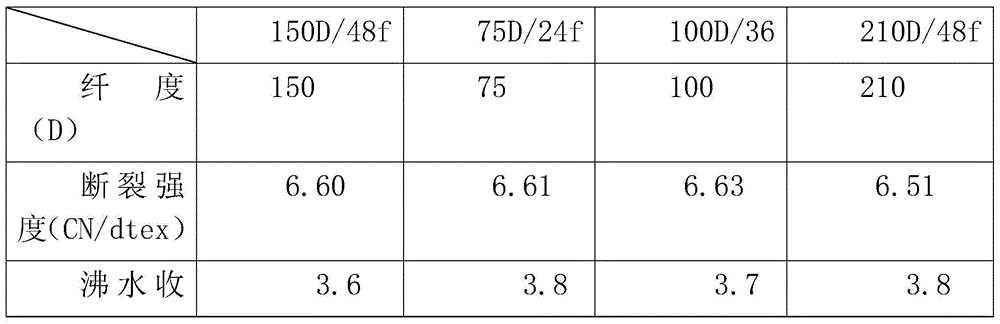

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com