Spinning apparatus for rotor spinning composite yarn

A technology of composite yarn and rotor spinning, which is applied in yarn, textile and papermaking, etc. It can solve the problems that are difficult to realize, difficult to carry out normally, and filament winding, etc., and achieve the effect of reducing end-breakage rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

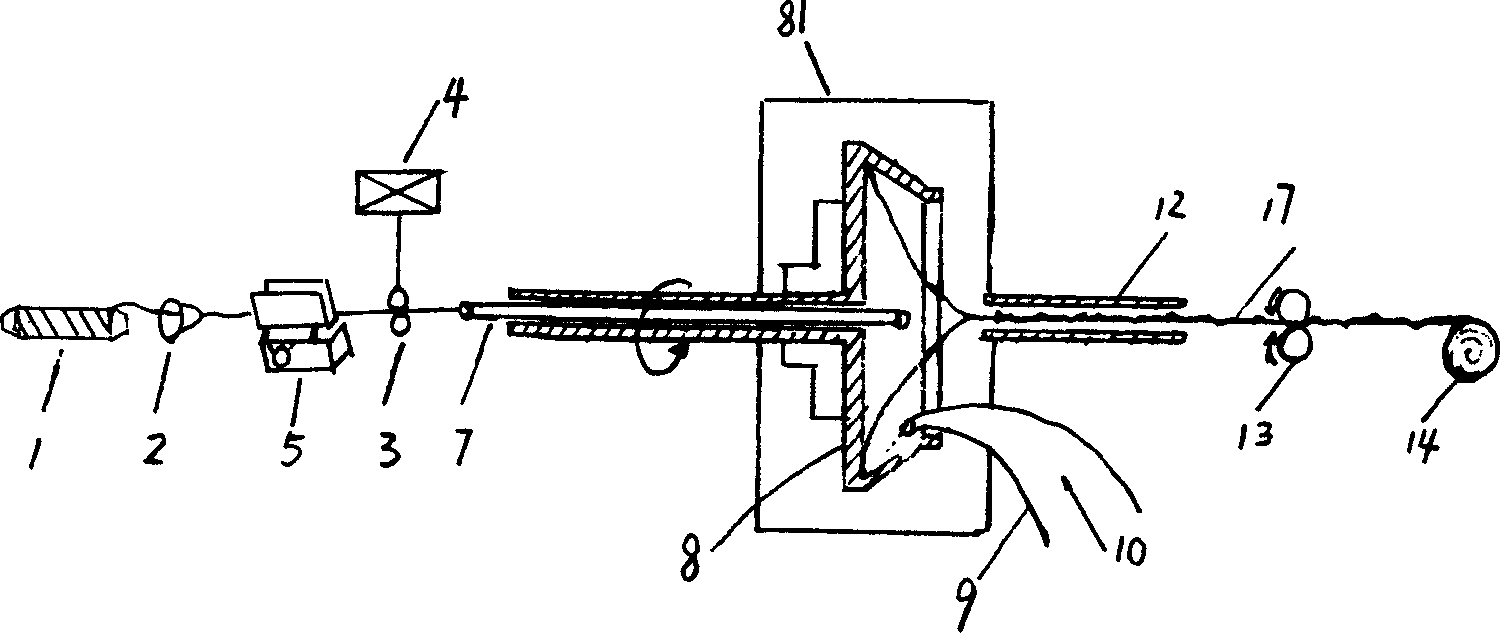

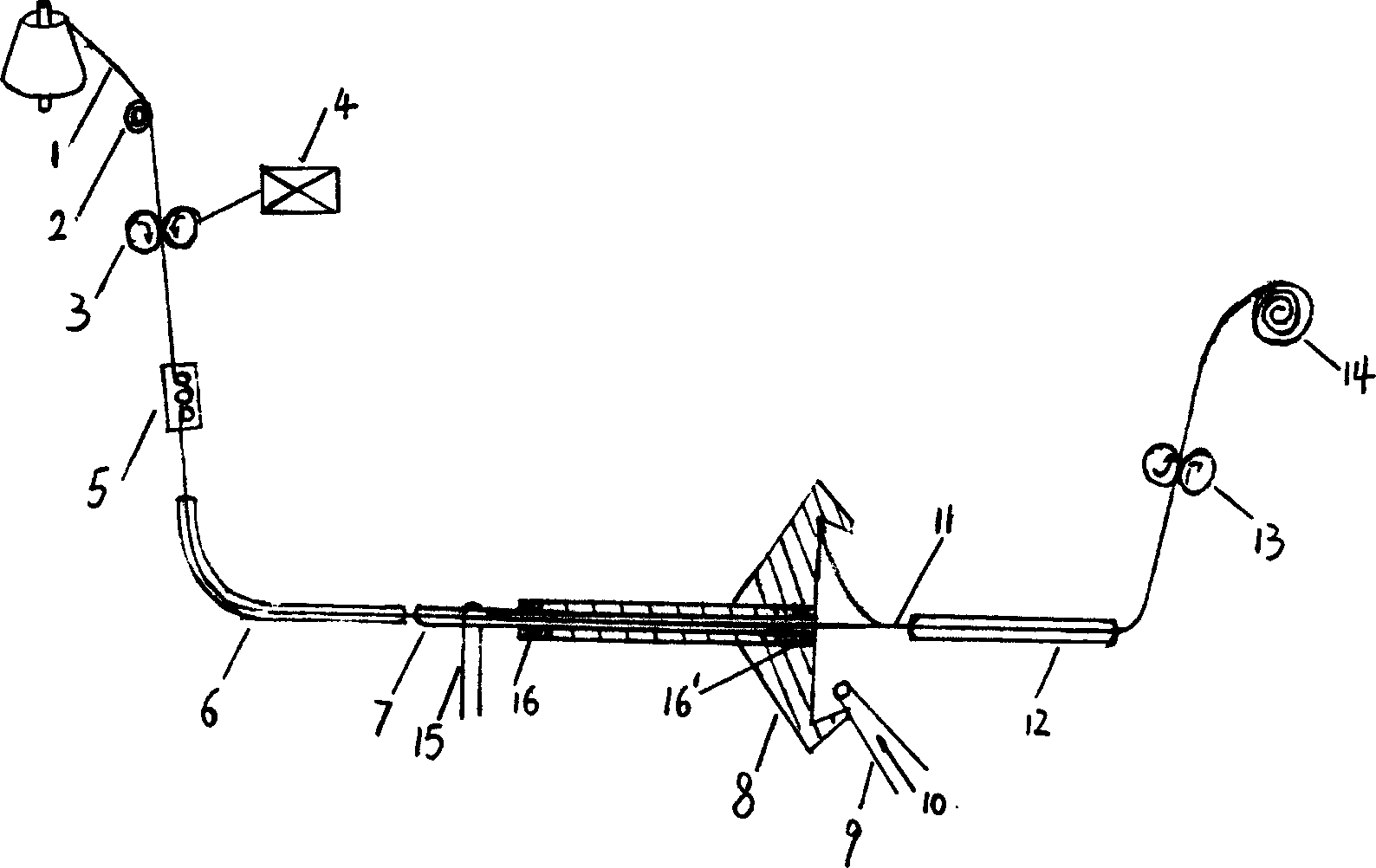

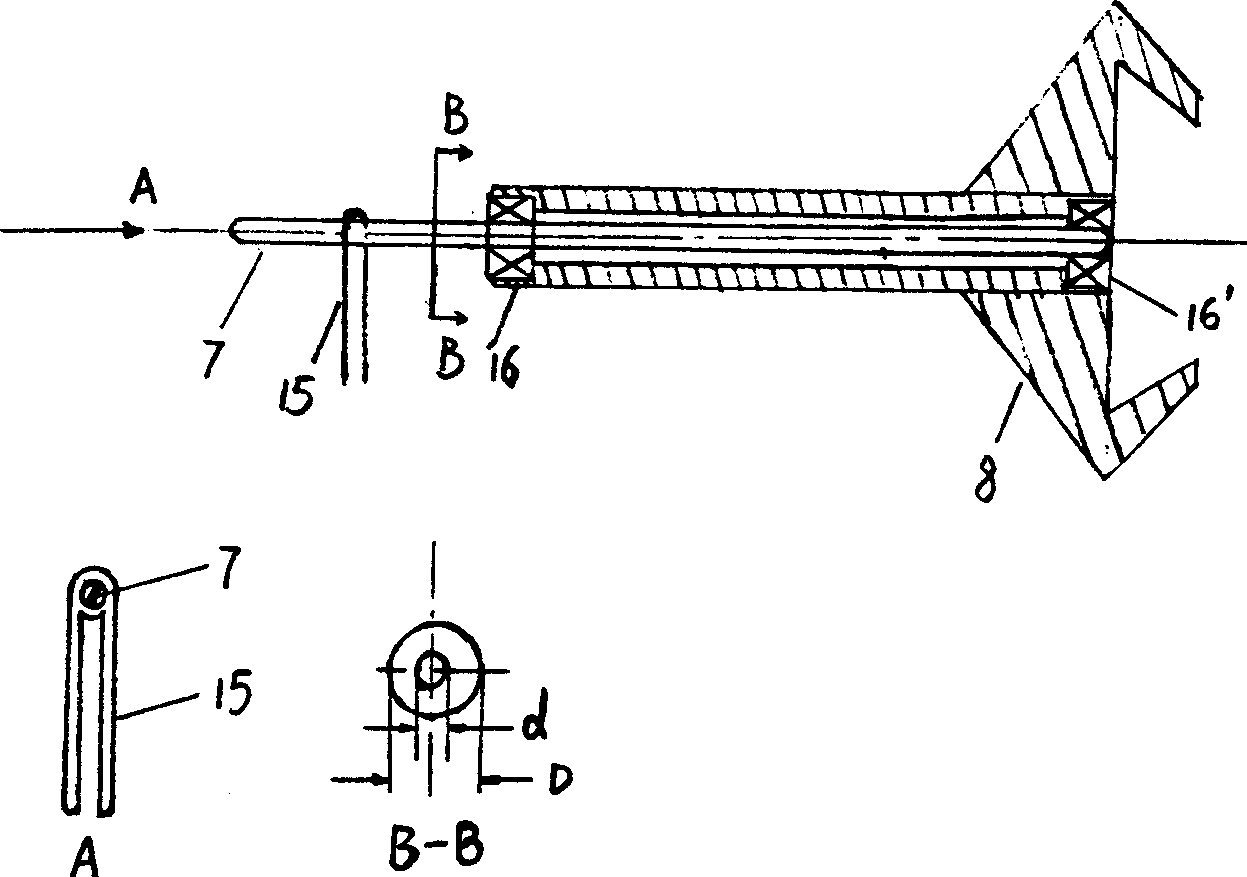

Method used

Image

Examples

Embodiment

[0039] Composite yarns with different structures and properties are spun on the rotor spinning machine of the present invention, wherein the proportion of filaments in the composite yarn is 5% to 30%:

[0040](1) When the ratio of the filament feeding speed to the yarn drawing speed of the composite yarn is 0.8, the composite yarn with a core-spun structure can be obtained, and the breaking strength of the composite yarn can be increased by 10% compared with the ordinary rotor-spun yarn with the same linear density, and the appearance is similar to that of the rotor-spun yarn. Ordinary rotor-spun yarns are similar, such as Figure 4 Figure (a) and Figure (b) in the figure;

[0041] (2) When the ratio of the filament feeding speed to the yarn drawing speed of the composite yarn is 0.98, the composite yarn with a strand structure can be obtained, and the breaking strength of the composite yarn can be increased by 5% compared with the ordinary rotor yarn with the same linear dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com