Polyester emulsion slurry and preparation method thereof

A polyester emulsion size, room temperature technology, used in fiber types, textiles and papermaking, fiber processing, etc., can solve the problems of high glass transition temperature and difficult to improve the hardness and brittleness of starch sizing films, and achieve good flexibility, elasticity, adhesion, etc. Good sex, the effect of reducing the rate of broken ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

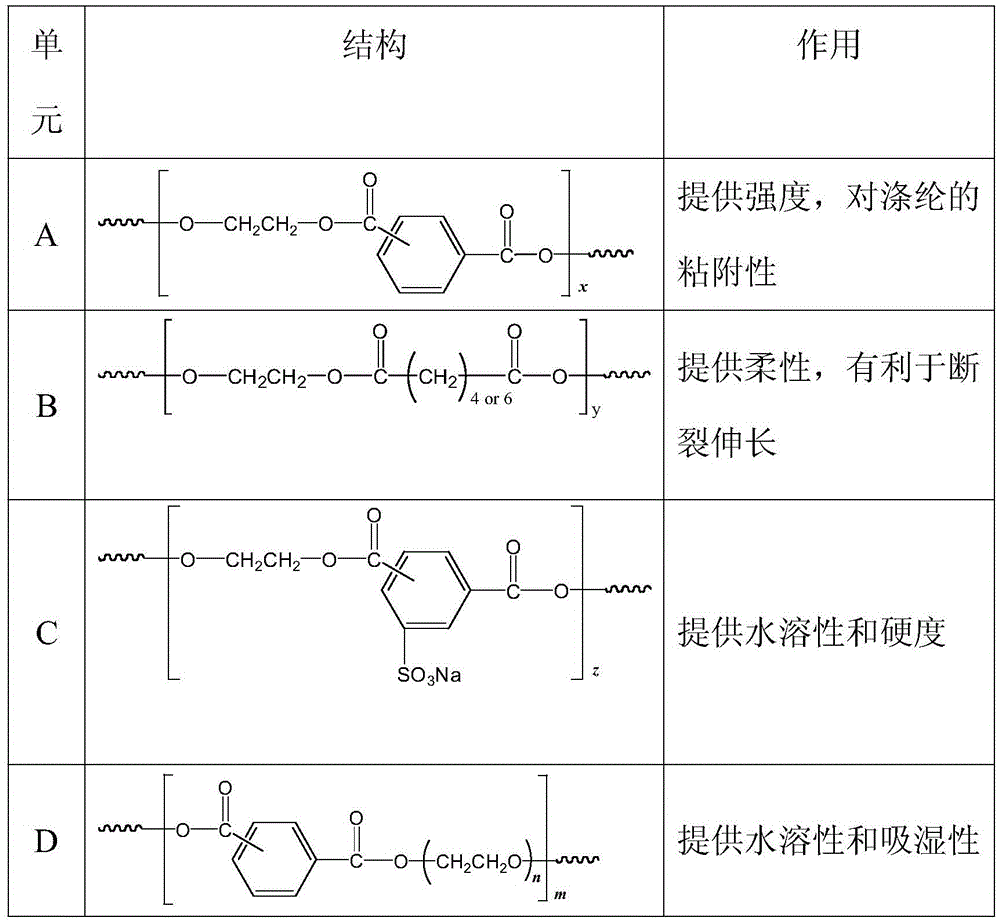

Method used

Image

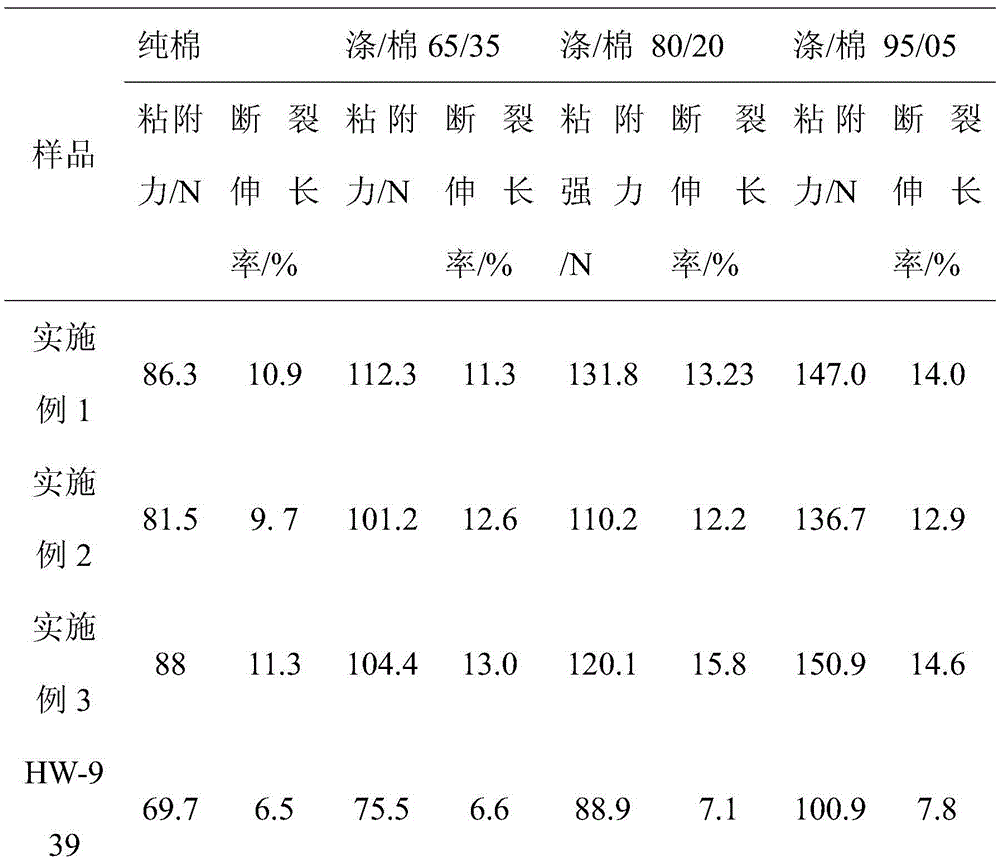

Examples

Embodiment 1

[0027] In the present embodiment, the polyester emulsion slurry is prepared in the polyester pilot test reactor as follows:

[0028] (1) Esterification: 60.19mol of purified terephthalic acid, 4.82mol of isophthalic acid, 3.73mol of sodium isophthalic acid-5-sulfonate, 27.37mol of 1,6-adipic acid, and 136.95mol of ethylene glycol , PEG-6000.5kg, 50g of catalyst monobutyltin oxide, and 40g of antioxidant 1010 were put into the pilot test reactor, stirred and mixed evenly, nitrogen was blown and the temperature was raised slowly, and the top temperature of the reflux condenser was controlled not to exceed 103°C. The reaction system When the temperature rises to 240-245°C, keep warm for esterification for 4-6 hours, until the theoretical effluent value of 3.5kg (192.22mol) is reached and the top temperature of the reflux condenser is not higher than 50°C to obtain a copolyester compound.

[0029] (2) Polycondensation: The temperature of the reaction system is lowered to 220°C±5, ...

Embodiment 2

[0033] (1) Esterification: 66.21mol of purified terephthalic acid, 4.75mol of isophthalic acid, 3.9mol of sodium isophthalic acid-5-sulfonate, 25.83mol of 1,8-suberic acid, and 136.95mol of ethylene glycol , PEG-10000.3kg, 50g of catalyst monobutyltin oxide and 40g of antioxidant 1010 were put into the pilot test reactor, stirred and mixed evenly, nitrogen was blown and the temperature was raised slowly, and the top temperature of the reflux condenser was controlled not to be higher than 103°C. The temperature of the reaction system When the temperature rises to 240°C, keep warm and esterify for 4-6 hours, until the theoretical effluent value of 3.6kg (201.18mol) is reached and the top temperature of the reflux condenser is not higher than 50°C to obtain a copolyester compound.

[0034] (2) Polycondensation: The temperature of the reaction system is lowered to 220°C±5, the nitrogen pipe is closed, and the polycondensation reaction is carried out under an absolute pressure of 10...

Embodiment 3

[0038](1) Esterification: 54.17mol of purified terephthalic acid, 9.03mol of isophthalic acid, 3.73mol of sodium isophthalic acid-5-sulfonate, 31.5mol of 1,6-adipic acid, and 128.89mol of ethylene glycol , put 50g of catalyst dibutyltin oxide and 40g of antioxidant 1010 into the reaction kettle, stir and mix evenly, blow nitrogen and slowly raise the temperature, control the top temperature of the reflux condenser to not be higher than 103°C, and keep warm when the temperature of the reaction system rises to 240°C After 4-6 hours, until the theoretical water output value is 3.5kg (195.44mol) and the top temperature of the reflux condenser is not higher than 50°C, a copolyester compound is obtained.

[0039] (2) Polycondensation: The temperature of the reaction system is lowered to 220°C±5, the nitrogen pipe is closed, and the polycondensation reaction is carried out under an absolute pressure of 100 Pa and vacuum for 3-5 hours to obtain a WPET melt.

[0040] (3) Emulsification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com