Low-density coated ceramic proppant prepared through fly ash and preparation method of low-density coated ceramic proppant

A fly ash, low-density technology, applied in the field of low-density film-coated ceramsite proppant and its preparation, can solve the problems of high cost of raw materials, high density of proppant, high cost of use, etc., to reduce firing temperature and increase strength , The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

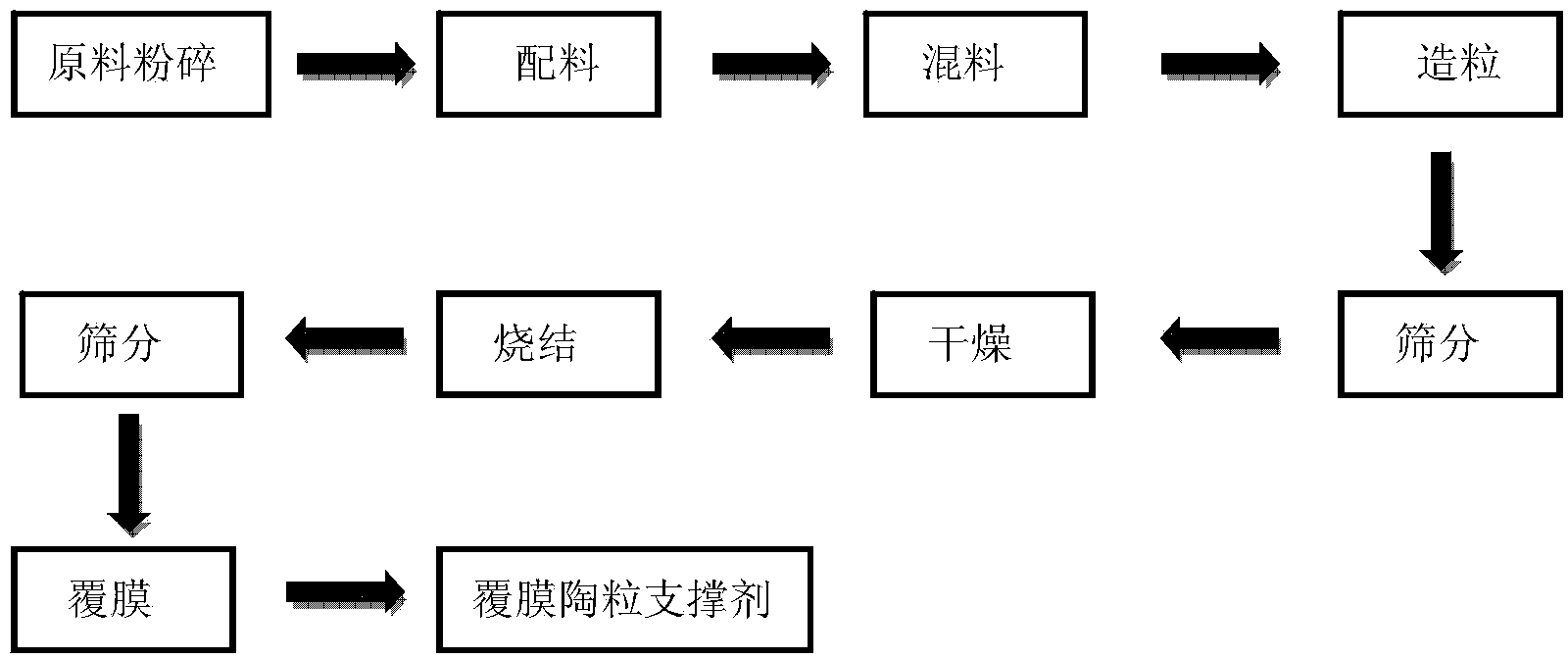

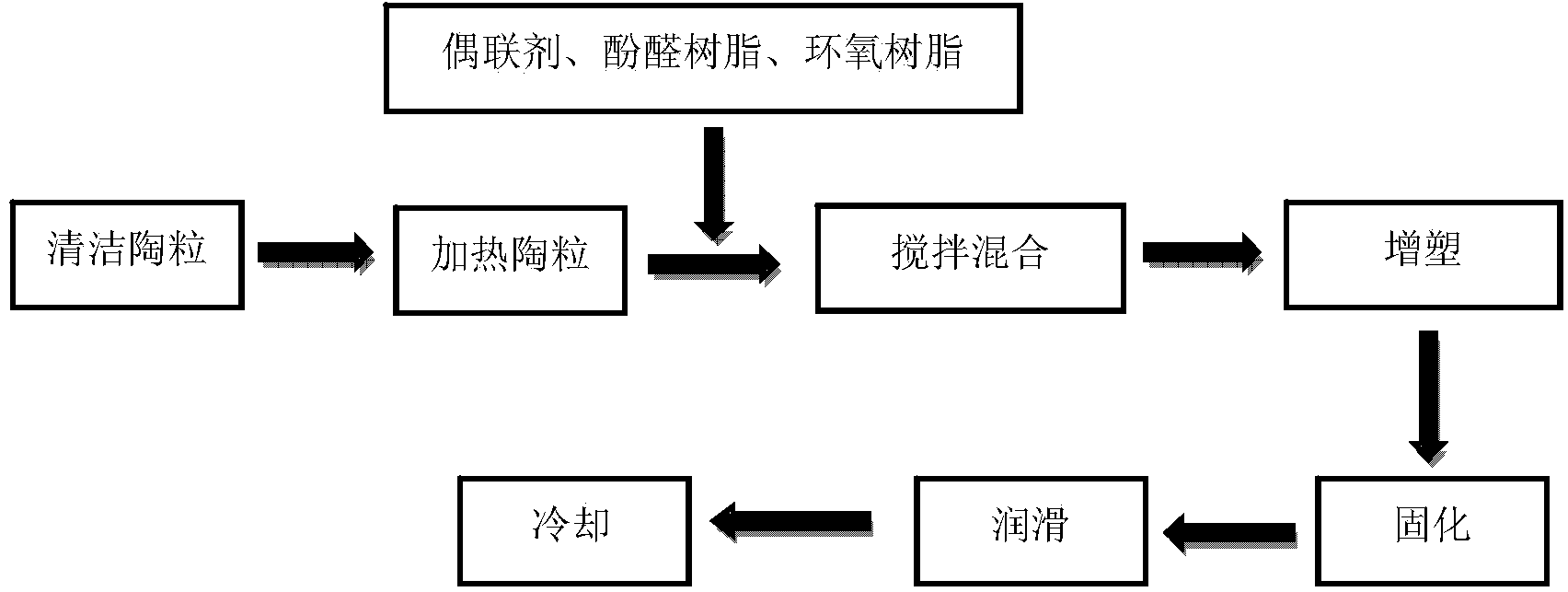

Method used

Image

Examples

Embodiment 1

[0036] 1) Prepare the raw materials, the raw materials are as follows: fly ash 93wt%, MnO 2 powder 2wt%, potassium feldspar 5wt%; all raw materials are crushed or ground to more than 325 mesh respectively, and then mixed uniformly in proportion; the fly ash used is high alumina fly ash, and its main chemical composition (by weight percentage) For: A1 2 o3 : 45%~55%, SiO 2 : 20%~35%, Fe 2 o 3 : 1%~3%, CaO: 4%~6%, TiO 2 : 1%~4%, the balance is a small amount of Na 2 O, MgO, K 2 O. MnO used 2 Analytical pure, of which: MnO 2 The content is not less than 85.0wt%, and the alkali metal and alkaline earth metal are ≤2.0wt% in terms of sulfate.

[0037] 2) Put the mixed material into the granulator, spray into the binder aqueous solution to granulate, obtain the ceramsite green body, and obtain the ceramsite green body after passing through a 16-30 mesh sieve;

[0038] 3) Dry the screened ceramsite green body at an ambient temperature of 80°C for 4 hours, then put it into an...

Embodiment 2

[0041] 1) Prepare the raw materials, the raw materials are as follows: fly ash 97wt%, MnO 2 Powder 3wt%. All the raw materials are crushed or ground to more than 325 mesh respectively, and then mixed uniformly in proportion; the fly ash used is high-alumina fly ash, and its main chemical composition (by weight percentage) is: A1 2 o 3 : 45%~55%, SiO 2 : 20%~35%, Fe 2 o 3 : 1%~3%, CaO: 4%~6%, TiO 2 : 1%~4%, the balance is a small amount of Na 2 O, MgO, K 2 O; used MnO 2 Analytical pure, of which: MnO 2 The content is not less than 85.0wt%, and the alkali metal and alkaline earth metal are ≤2.0wt% in terms of sulfate.

[0042] 2) Put the mixed material into the granulator, spray into the binder aqueous solution to granulate, obtain the ceramsite green body, and obtain the ceramsite green body after passing through a 16-30 mesh sieve;

[0043] 3) Dry the screened ceramsite green body at 100°C for 3.5 hours, then put it into an electric furnace, raise it to 400°C at a ...

Embodiment 3

[0046] 1) Prepare the raw materials, the raw materials are as follows: fly ash 92wt%, MnO 2 Powder 1wt%, potassium feldspar 7wt%; all raw materials are crushed or ground to more than 325 mesh respectively, and then mixed uniformly in proportion; the fly ash used is high alumina fly ash, and its main chemical composition (by weight percentage) For: A1 2 o 3 : 45%~55%, SiO 2 : 20%~35%, Fe 2 o 3 : 1%~3%, CaO: 4%~6%, TiO 2 : 1%~4%, the balance is a small amount of Na 2 O, MgO, K 2 O. MnO used 2 Analytical pure, of which: MnO 2 The content is not less than 85.0wt%, and the alkali metal and alkaline earth metal are ≤2.0wt% in terms of sulfate.

[0047] 2) Put the mixed material into the granulator, spray into the binder aqueous solution to granulate, obtain the ceramsite green body, and obtain the ceramsite green body after passing through a 16-30 mesh sieve;

[0048] 3) Dry the screened ceramsite green body at 120°C for 3 hours, then put it into an electric furnace, firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com