Combined-type buckwheat shelling machine

A composite buckwheat hulling machine and composite buckwheat technology are applied in grain hulling, grain processing, application and other directions, which can solve the problems of few stress points, high buckwheat rice crushing rate, low hulling work efficiency, etc. It can achieve the effect of large comprehensive stress area, high shelling efficiency and good effect of impurity removal and dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

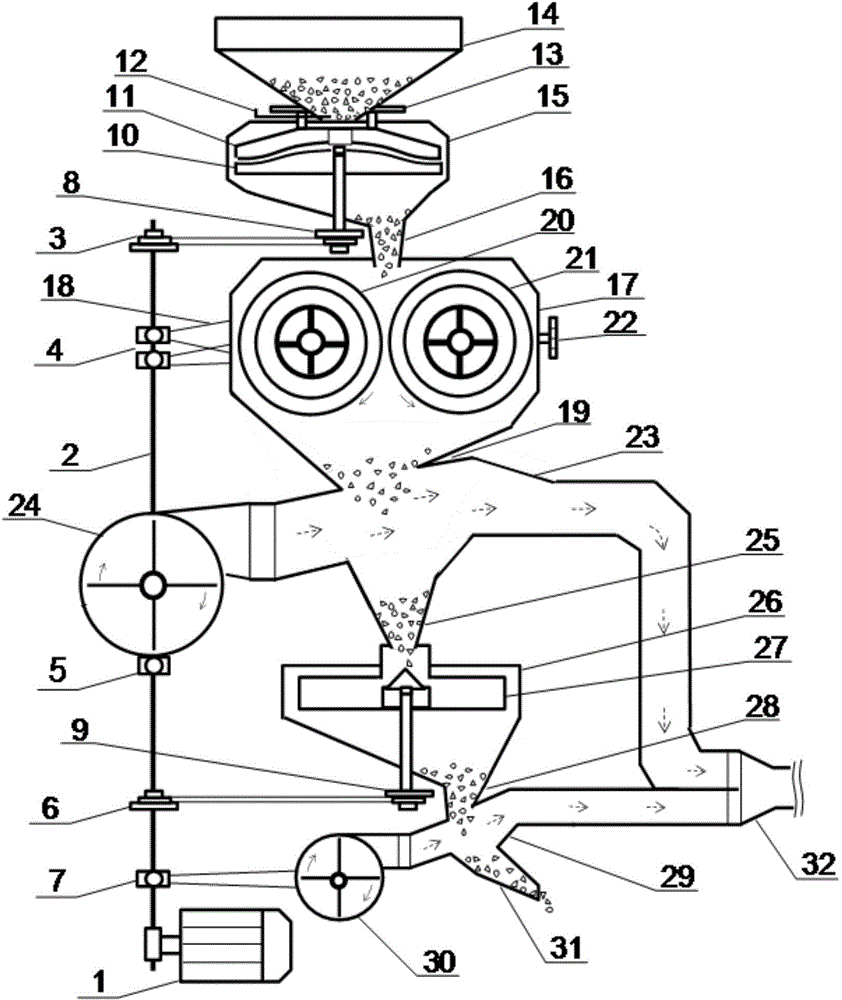

[0029] The present invention will be further described below in conjunction with accompanying drawing:

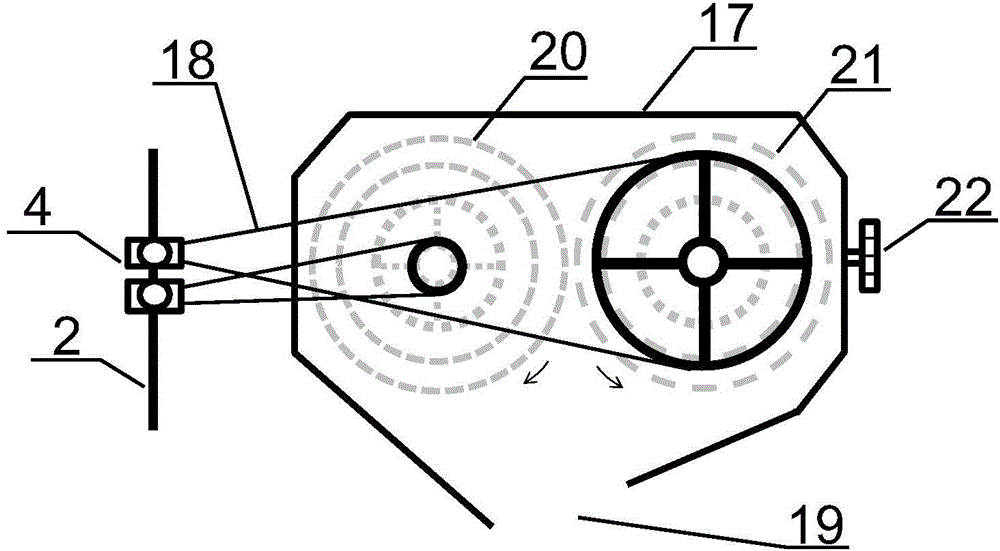

[0030] Such as figure 1 As shown, the composite buckwheat hulling machine includes a motor 1 connected to the main shaft 2, and the main shaft 2 is sequentially connected with a pulley 3, a gear-pulley 4, a gear-pulley 5, a pulley 6 and a gear-pulley 7, and the pulley 3 and pulley 6 are connected with pulley 8 and pulley 9 by drive belt respectively.

[0031] Belt pulleys 3, 6, 8, and 9 are all made of belt pulleys with different radii, and the rotating speed can be adjusted by selecting belt pulleys with different radii. Convert the horizontal rotation direction of spindle 2 to the vertical rotation direction.

[0032] The belt pulley 8 is connected with a rotating disc 10 through a shaft, and a fixed disc 11 is correspondingly arranged above the rotating disc 10. The rotating disc 10 is a disc-shaped rubber disc, and the fixed disc 11 is a disc-shaped sand disc; the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com