Method for cutting tempered glass

A technology for strengthening glass and cutting methods, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of easy breakage of glass, low production efficiency, and reduced glass strength, so as to reduce the breakage rate, improve production efficiency, The effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

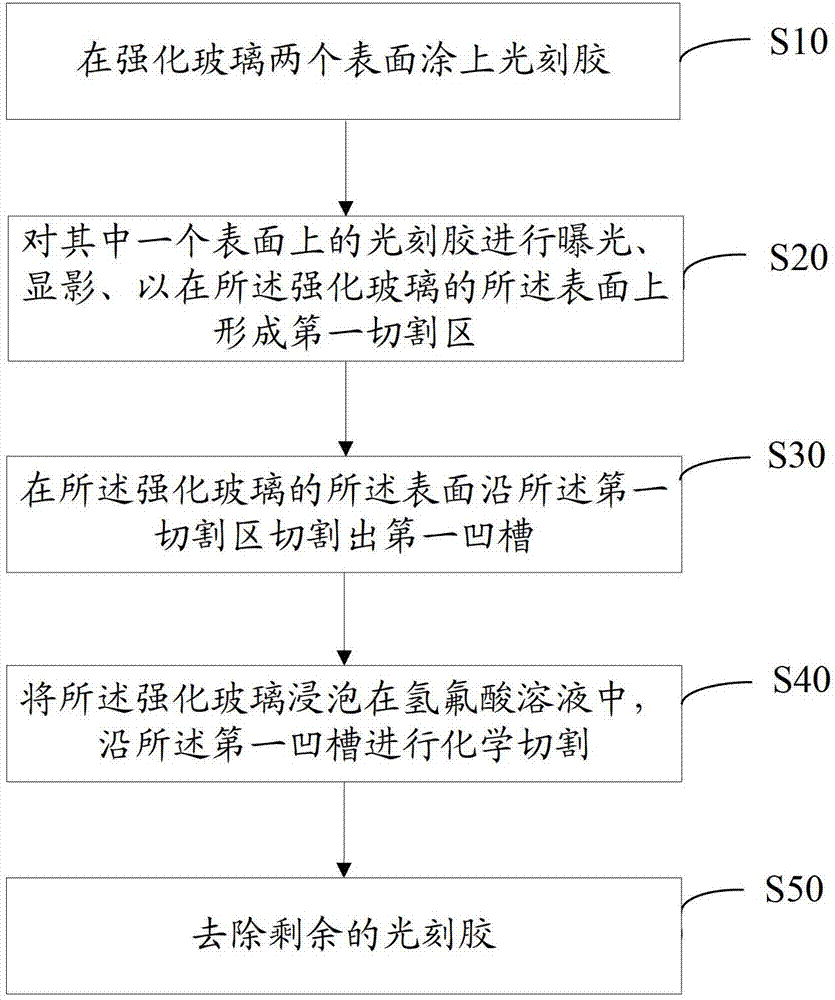

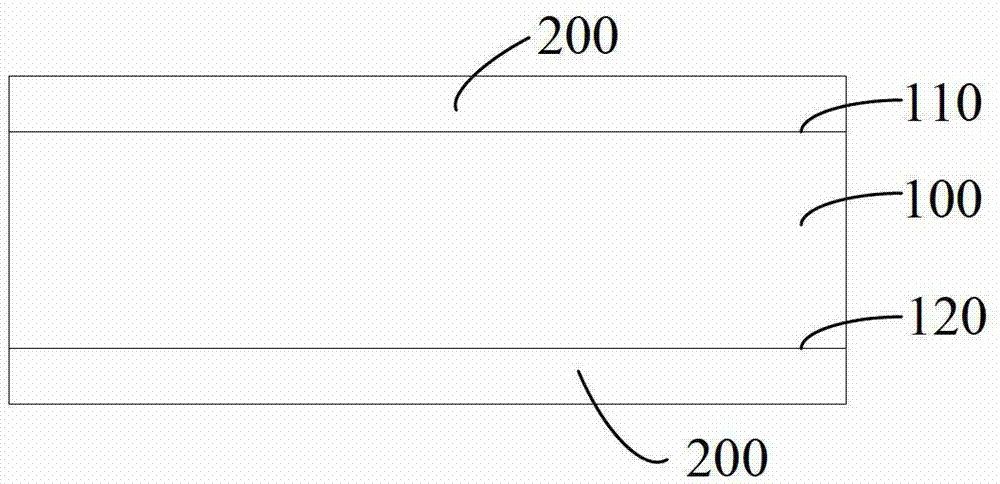

[0055] Coat 50 μm photoresist on both surfaces of the strengthened glass.

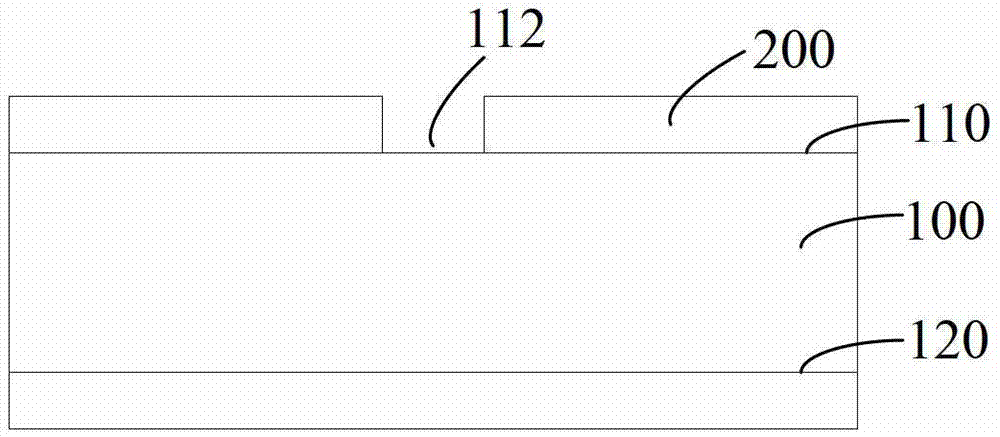

[0056] Exposing and developing the photoresist on one of the surfaces to form a first cutting area on the surface of the strengthened glass.

[0057] A V-shaped groove with a depth of 0.03 mm is cut along the first cutting zone on the surface of the strengthened glass.

[0058] The strengthened glass is soaked in a hydrofluoric acid solution with a concentration of 40% by mass, and chemically cut along the V-shaped groove.

[0059] Use the stripper Ecostrip to remove the remaining photoresist.

[0060] Wherein, the thickness of the strengthened glass is 0.77mm, the immersion temperature is 33°C, and the immersion time is 900s.

Embodiment 2

[0062] Coat 100 μm photoresist on both surfaces of the strengthened glass.

[0063] Exposing and developing the photoresist on one of the surfaces to form a first cutting area on the surface of the strengthened glass.

[0064] A square groove with a depth of 0.08 mm is cut along the first cutting zone on the surface of the strengthened glass.

[0065] The strengthened glass is soaked in a hydrofluoric acid solution with a concentration of 30% by mass, and chemically cut along the square groove.

[0066] Use the stripper Ecostrip to remove the remaining photoresist.

[0067] Among them, the thickness of the strengthened glass is 0.77mm, the soaking temperature is 33°C, and the soaking time is 3600s.

Embodiment 3

[0069] Coat 50 μm photoresist on both surfaces of the strengthened glass.

[0070] The photoresist on both surfaces is exposed, developed to form two cutting regions on the surface of the strengthened glass.

[0071] V-shaped grooves with a depth of 0.08 mm are cut along the two cutting regions on the surface of the strengthened glass.

[0072] The strengthened glass is soaked in a hydrofluoric acid solution with a concentration of 30% by mass, and chemically cut along the V-shaped groove.

[0073] Use the stripper Ecostrip to remove the remaining photoresist.

[0074] Wherein, the thickness of the strengthened glass is 0.77mm, the immersion temperature is 33°C, and the immersion time is 1200s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com