Automatic polishing machine for two ends of plate

An automatic polishing and double-head technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., to achieve a wide range of uses, reduce damage rates, and overcome the cracking of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

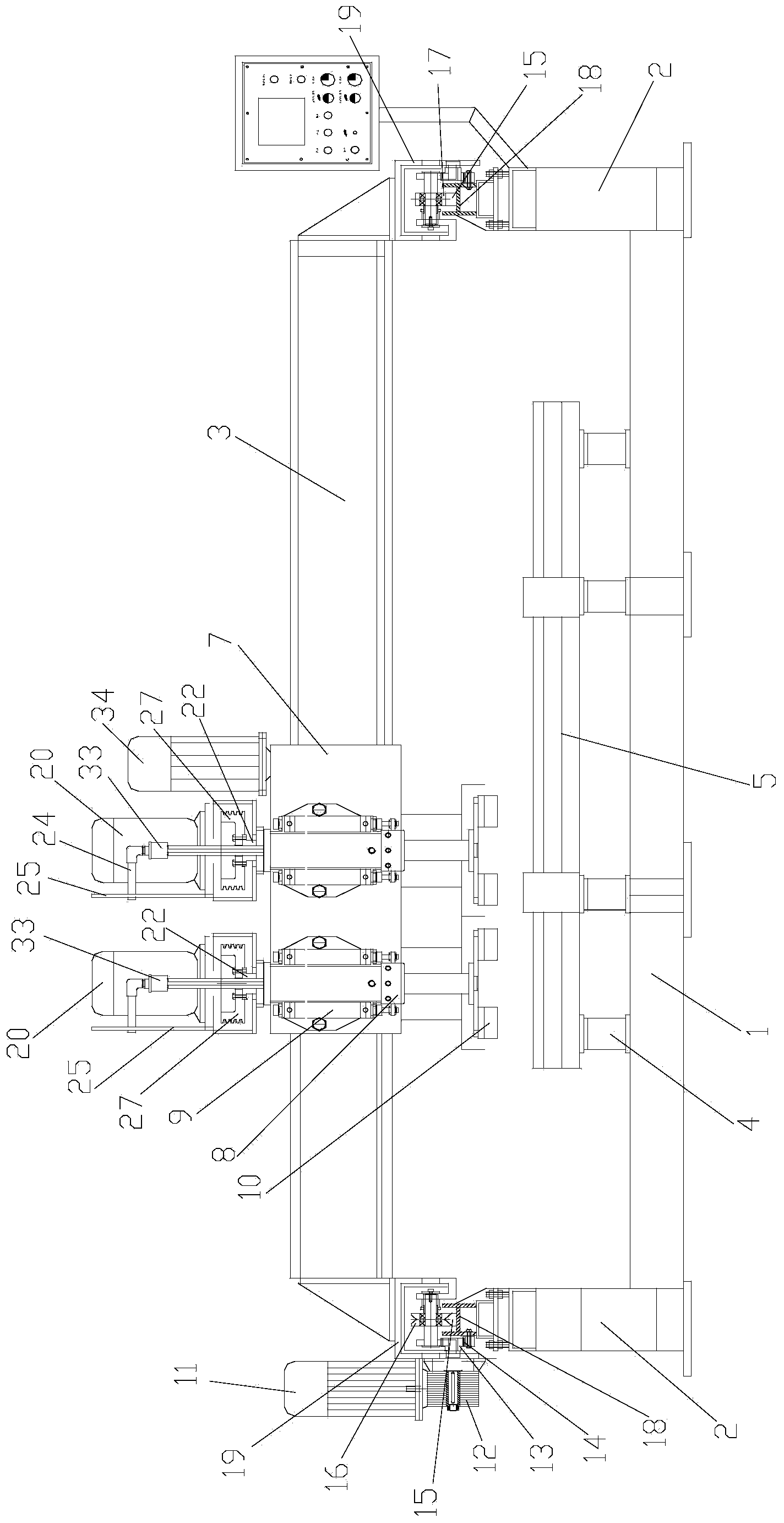

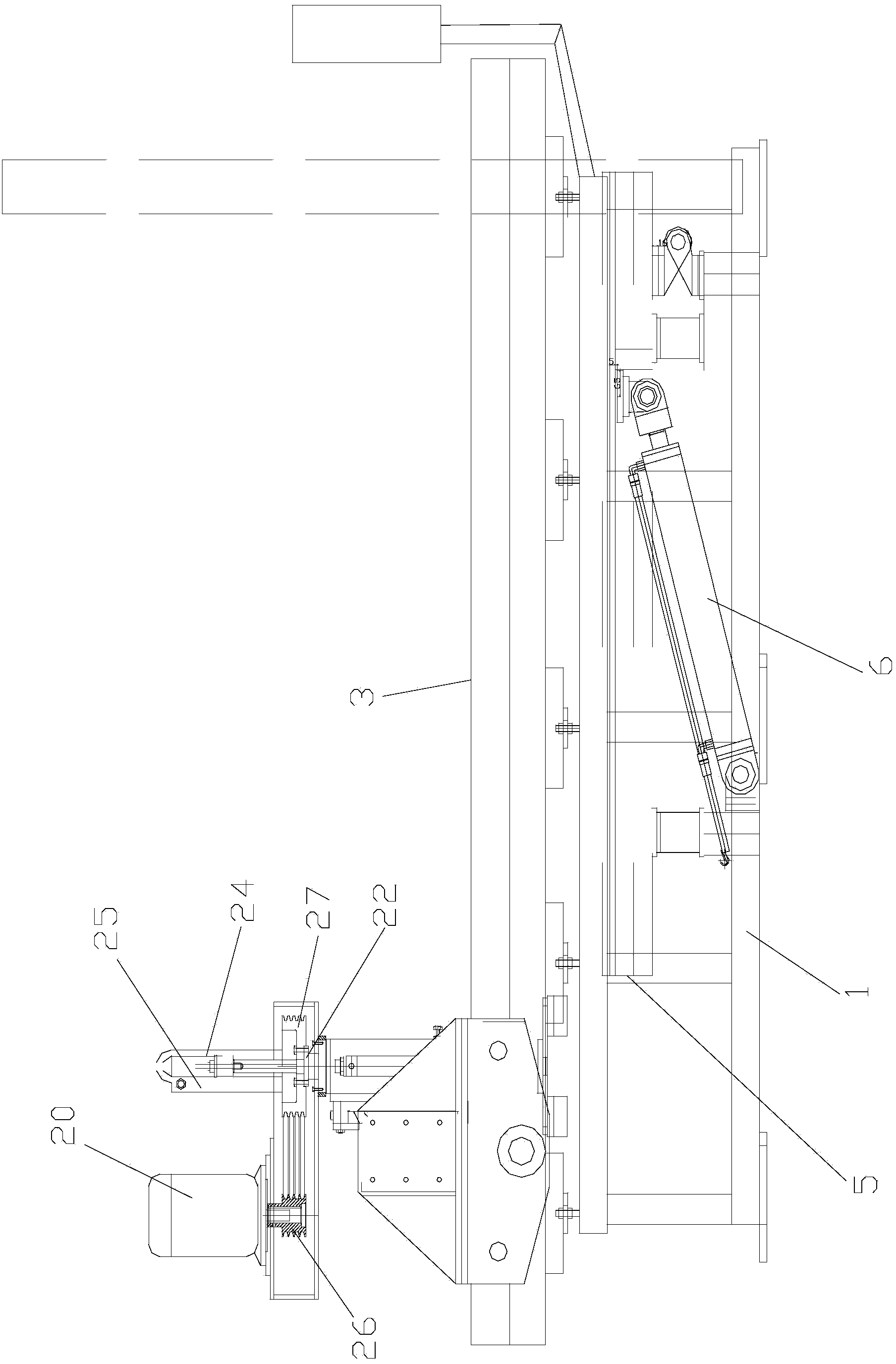

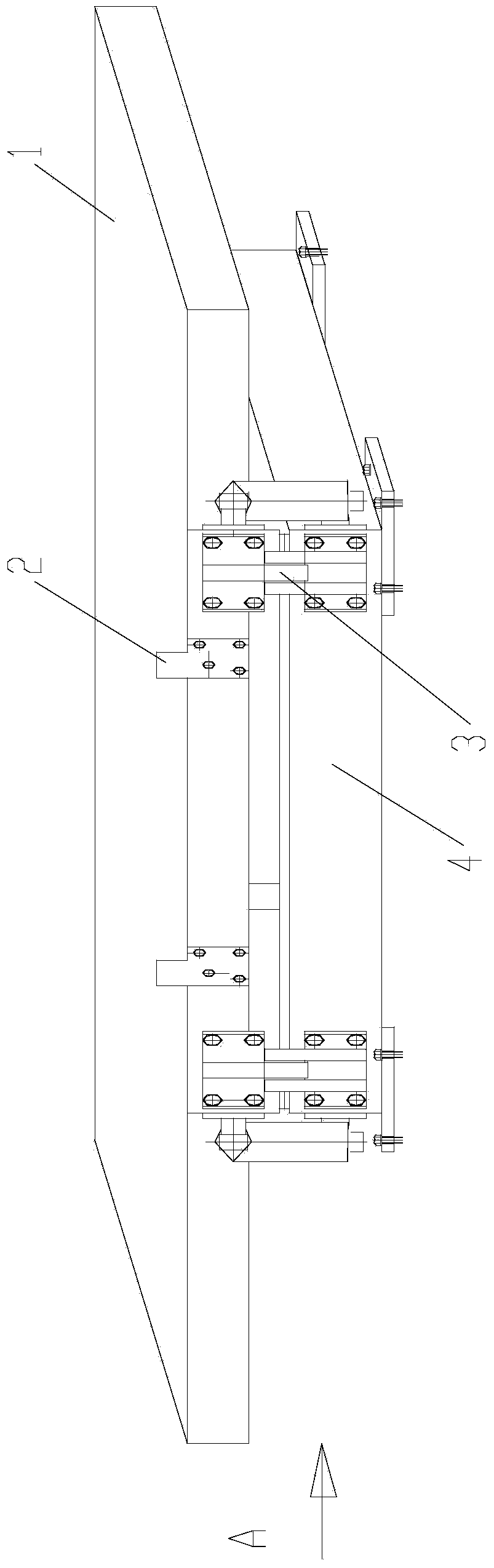

[0024] Attached below Figure 1-8 An embodiment of the present invention is described.

[0025] The plate double-head automatic polishing machine has a base 1, a leg 2 and a beam 3. The base 1 is fixed with a support 4 and a worktable 5 located at the upper end of the base 1 is hinged to the right end of the base 1 and supported on the base by the support 4 On 1, there is a hydraulic cylinder 6 for turning the workbench 5 between the base 1 and the workbench 5. One end of the hydraulic cylinder 6 is fixed in the middle of the base 1, and the piston rod at the other end of the hydraulic cylinder 6 is fixed at the right end of the workbench 5 , The cross beam 3 is provided with a cross beam moving device at both ends, and the cross beam moving device drives the cross beam 3 to move back and forth along the legs 2. Specifically, the cross beam moving device includes a moving motor 11, a reducer 12, a gear I 13, a rack I 14, The guide rail 15, the V-shaped wheel 16 and the flat roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com