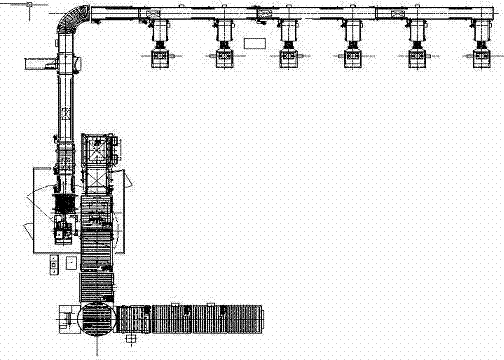

Full-automatic valve bag packaging and stacking production line

A valve bag and production line technology, applied in the field of powder valve bag automatic valve bag packaging and palletizing production line, can solve the problems of not meeting production requirements, endangering workers' health, low work efficiency, etc., and achieving compact structure and high degree of automation. , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

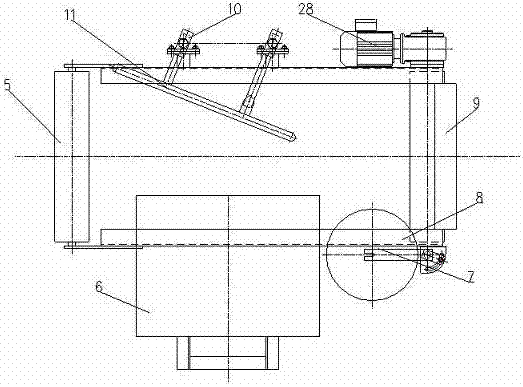

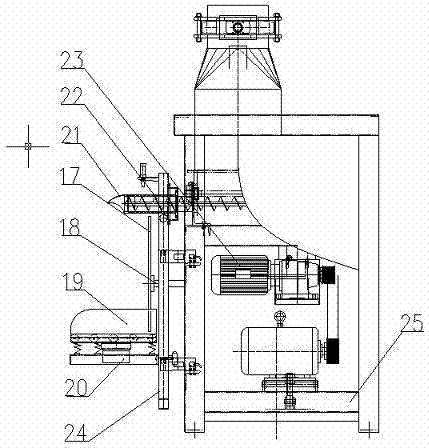

[0020] Combine below Figure 1-5 The present invention is described further:

[0021] During work, the valve bag is manually placed on the discharge port 21 of the valve bag packaging machine 4, the packaging switch is started, and the screw conveyor 22 rotates to start feeding; during the feeding process, the vibration motor 20 drives the platform 19 to vibrate the material, and when the material reaches When the set packing value is reached, the screw conveyor stops rotating and the packing ends. Then the pushing cylinder 18 drives the pushing plate 17 to push out the material bag; at this time, the bag-inverting output machine 2 starts, and the material bag is automatically adjusted to the inclined plate 6, the guide roller 8, and the guide rod 11 to put the vertical bag down; The material bag after falling is output after the material bag is turned 90 ° through the rotating roller 26 on the leather bag conveyor 3. This production line adopts six-station packaging, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com