Washing machine and operating method thereof

A working method and washing machine technology, applied to other washing machines, washing machine appliances, washing machines with containers, etc., can solve problems such as poor dehydration effect, achieve the effects of reducing production costs, simplifying the structure, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

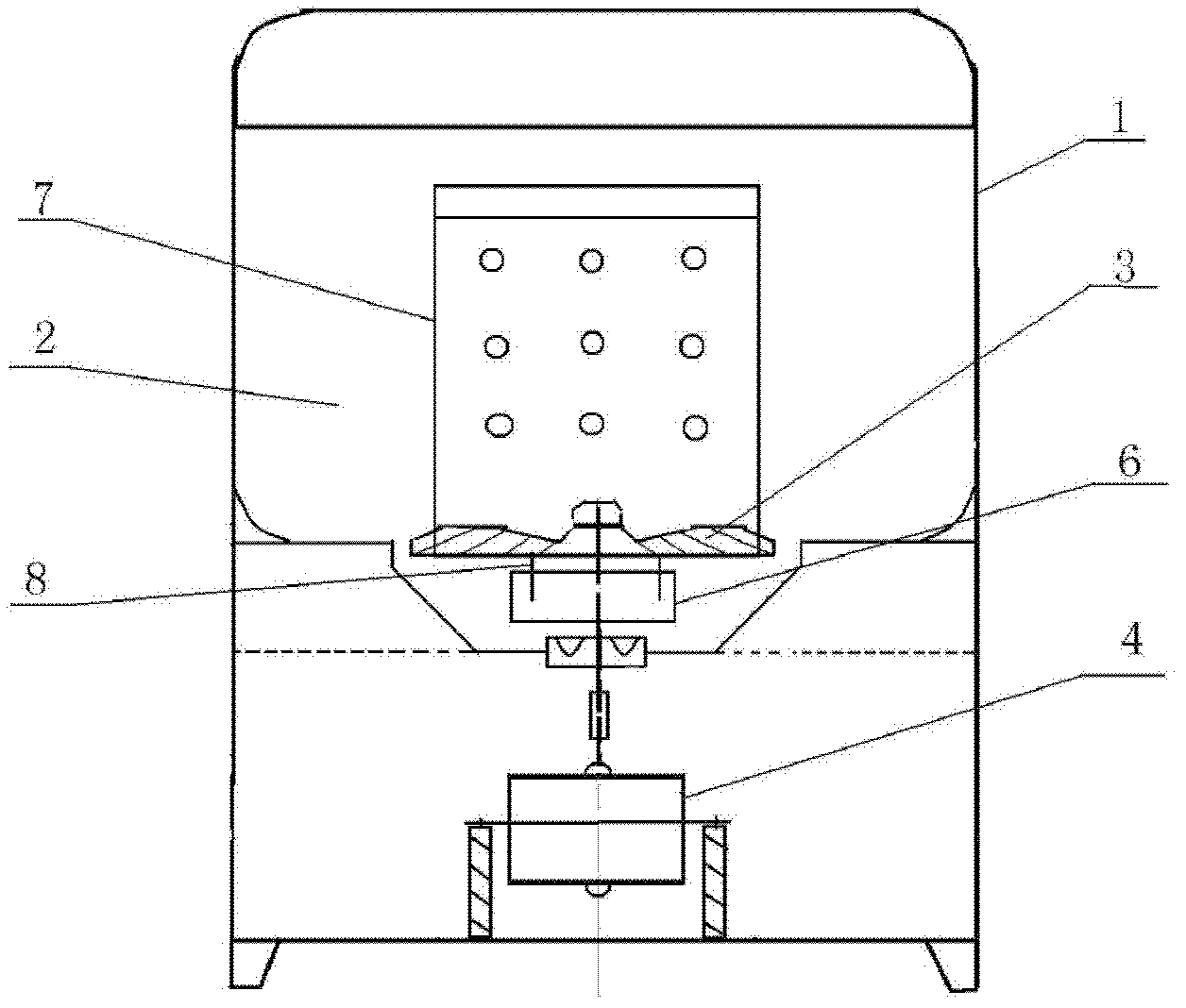

[0026] Such as figure 1 As shown, the washing machine described in this embodiment includes a washing machine barrel and a removable dehydration barrel. The washing machine barrel is provided with a washing chamber, a pulsator, a motor, a speed reducer and a speed reducer cover, and the speed reducer is fixed in the speed reducer cover. ; During dehydration, the bolt arranged at the bottom of the dehydration barrel passes through the pulsator and is inserted into the reducer cover so that the dehydration barrel, the pulsator and the reducer are connected into one and rotate together.

[0027] The working method of the washing machine designed in the present invention uses a motor and a reducer to provide power for the pulsator. When washing, the output power of the motor is decelerated by the reducer to drive the pulsator to rotate; When dehydrating, the dehydration bucket, pulsator and reducer are integrated into one through the insert part set at the bottom of the dehydratio...

Embodiment 2

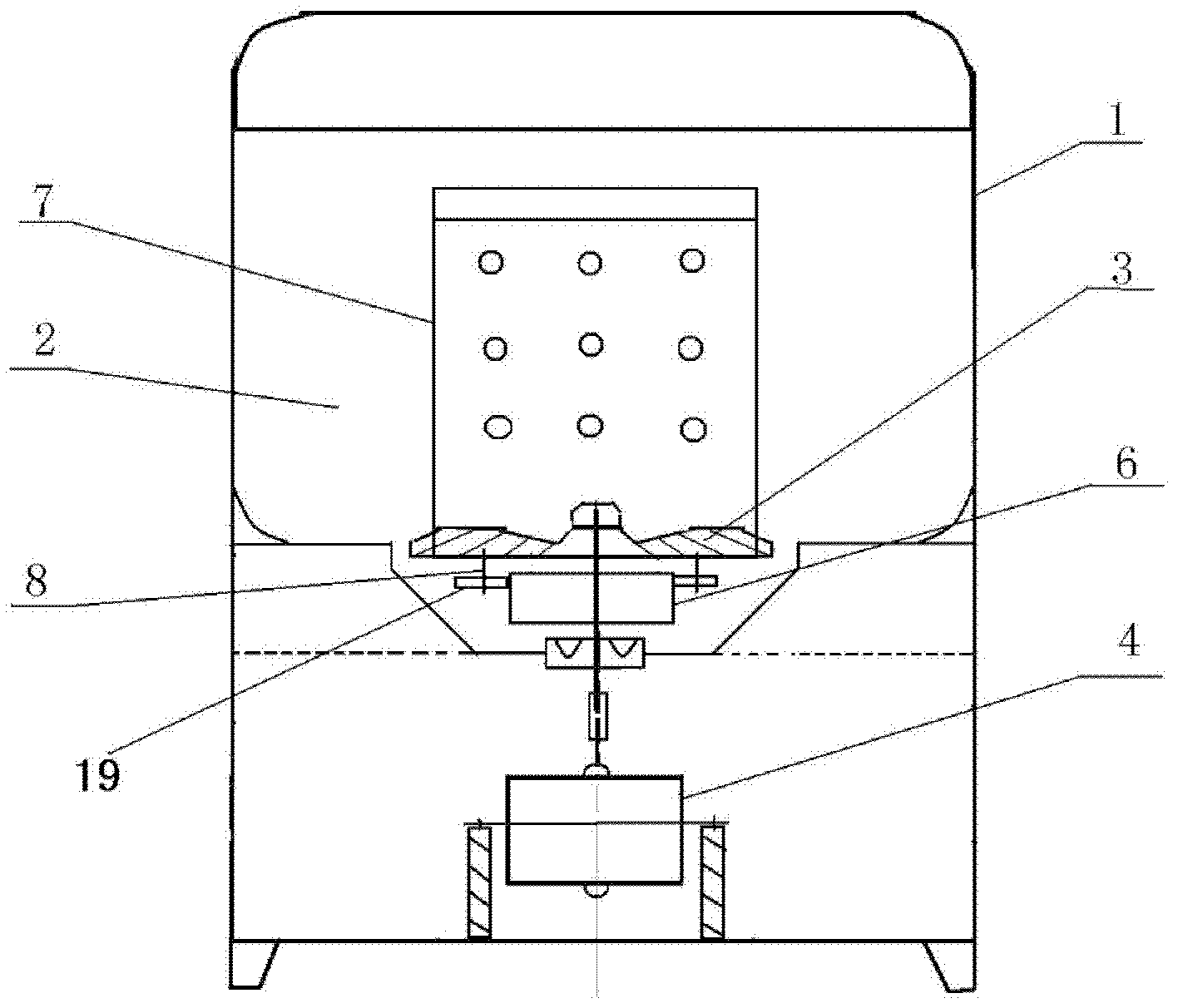

[0029] Such as figure 2 As shown, the washing machine described in this embodiment is different from Embodiment 1 in that during dehydration, the pin arranged at the bottom of the dehydration bucket passes through the pulsator and is inserted into the socket seat provided on the reducer cover, so that the dehydration bucket, pulsator The wheel and the reducer are connected into one body to rotate together.

Embodiment 3

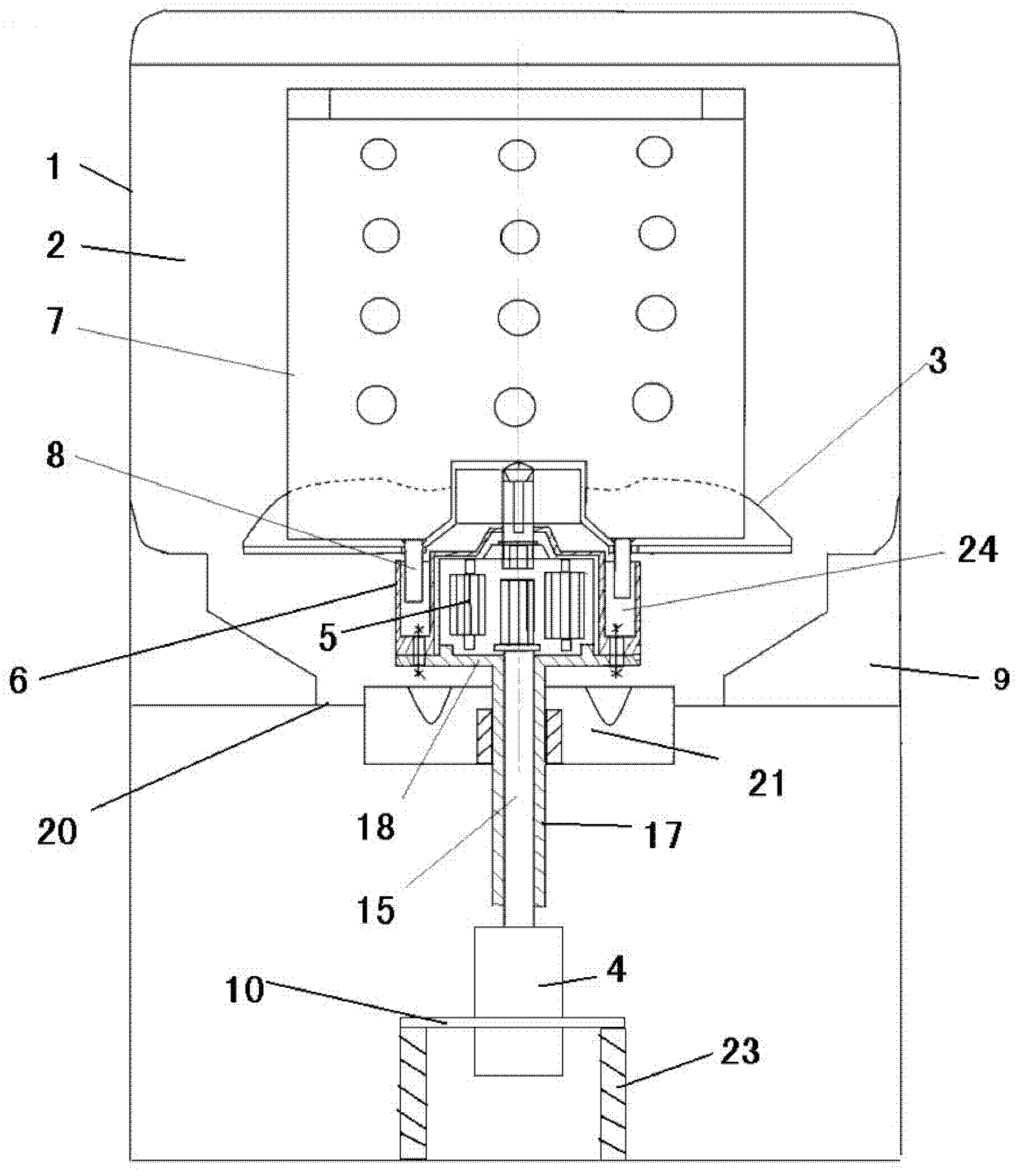

[0031] Such as image 3 As shown, in the washing machine described in this embodiment, the barrel body includes an upper barrel body and a lower barrel body separated by an interlayer, and the upper barrel body is provided with a washing chamber, a pulsator with a jack, a speed reducer and a speed reducer cover, A motor is arranged in the lower barrel, and a transmission shaft is connected above the motor. The transmission shaft is connected to the input end of the reducer after passing through a relatively rotatable sleeve, and the output end of the reducer is connected to the wave wheel; Through the interlayer, the reducer cover is fixedly connected to the upper end of the shaft sleeve; a leak-proof leather cup is provided at the passage of the shaft sleeve on the interlayer. Described motor is fixed on the motor base, and motor base is fixed in staving by shock-absorbing spring.

[0032] Such as Figure 4 As shown, the lower bottom surface of the reducer cover and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com