Bodybuilding washing machine with power transmission device

A technology of power transmission device and washing machine, which is applied to the control device of washing machine, washing device, other washing machines, etc., can solve the problems of damage to the commutation device and incomplete commutation, achieve stable and reliable transmission relationship, ensure washing effect and dehydration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

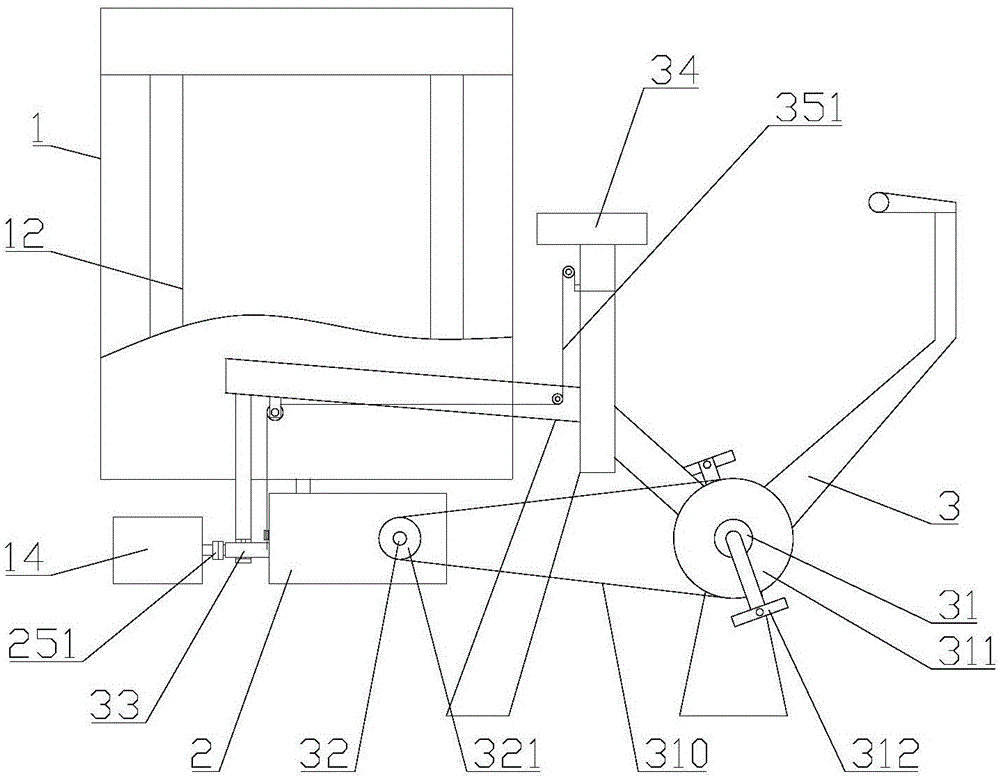

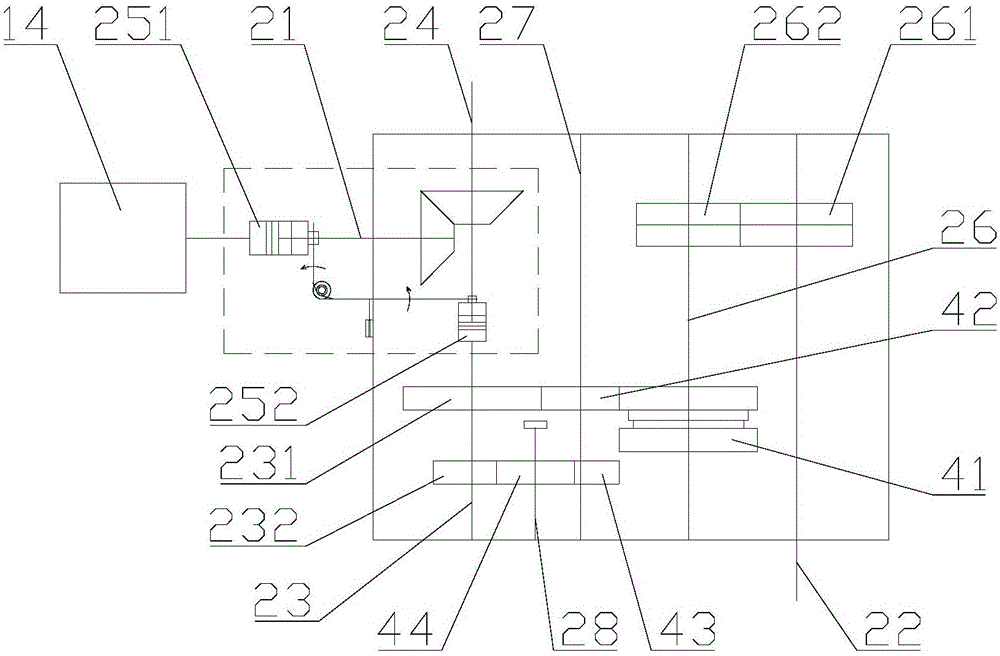

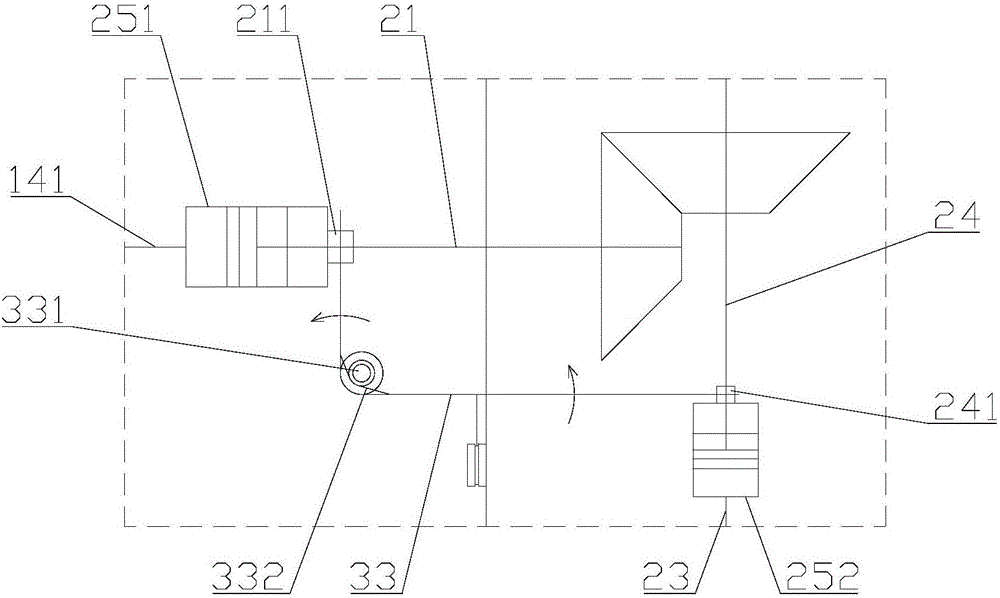

[0031] refer to Figure 1 to Figure 6 , the present invention provides a power transmission device for a fitness washing machine, comprising a washing machine motor 14, a reduction box 2 and a fixed frame 3, the fixed frame 3 is provided with a front shaft 31 and a rear shaft 32, and the front shaft 31 is provided with a front sprocket 311 , the rear axle 32 is provided with a rear sprocket 321, the front sprocket 311 and the rear sprocket 321 are connected by a chain 310 transmission, the front axle 31 is provided with a pedal 312, and the reduction box 2 is provided with a first input shaft 21, a second Two input shafts 22, an intermediate shaft 23 and an output shaft 24; the first input shaft 21 is connected with the motor shaft 141 of the laundry motor 14 through the first clutch 251, and the first input shaft 21 is connected with the output shaft 24 through gear transmission; the intermediate shaft 23 It is coaxial with the output shaft 24 and connected through the second...

Embodiment 2

[0037] Such as Figure 7 As shown, this embodiment is similar to Embodiment 1, the difference is:

[0038] The control mechanism is to rotate the clutch wrench 36 connected on the handle 37. A second steel wire rope 352 is connected between the clutch wrench 36 and the lever 33. The second steel rope 352 is connected to the end connected to the first sleeve 211 on the lever 33. The lever After 33 tilts to the first sleeve 211, the clutch wrench 36 opens relative to the handle 37. After the clutch wrench 36 and the handle 37 are closed, the lever 33 tilts to the second sleeve 241, and a clutch wrench 36 and the handle 37 are provided to make the clutch The spring that the wrench 36 and the handle 37 are opened, the handle 37 is provided with a lock that locks after the clutch wrench 36 and the handle 37 are closed.

[0039] The remaining implementation modes of this embodiment are the same as that of Embodiment 1.

Embodiment 3

[0041] In this embodiment, the clutch control is simpler and more convenient. Both the first clutch 251 and the second clutch 252 are electromagnetic clutches, and the fixed frame is provided with a power selection switch and a control circuit. The switch is connected in the control circuit. The power selection switch is a single-pole double-throw switch. The power selection switch has a first position and a second position. The first position is conducting and the second position is disconnecting. The clutch 252 is in a disengaged state, the first position is disconnected, the second position is conducted, the first clutch 251 is in a disengaged state, and the second clutch 252 is in an engaged state. After starting the washing machine, the user can select whether it is an electric washing machine or a human-driven washing machine by operating the power selection switch, which is intuitive and convenient.

[0042] The remaining implementation modes of this embodiment are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com