Granular preserved fruit food ingredient system and method

A technology of food ingredients and granules, which is applied in confectionery, confectionary industry, food science, etc., can solve problems such as uneven ingredients, excessive moisture, and food quality degradation, and achieve simple installation, improved food quality, and improved mixing uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

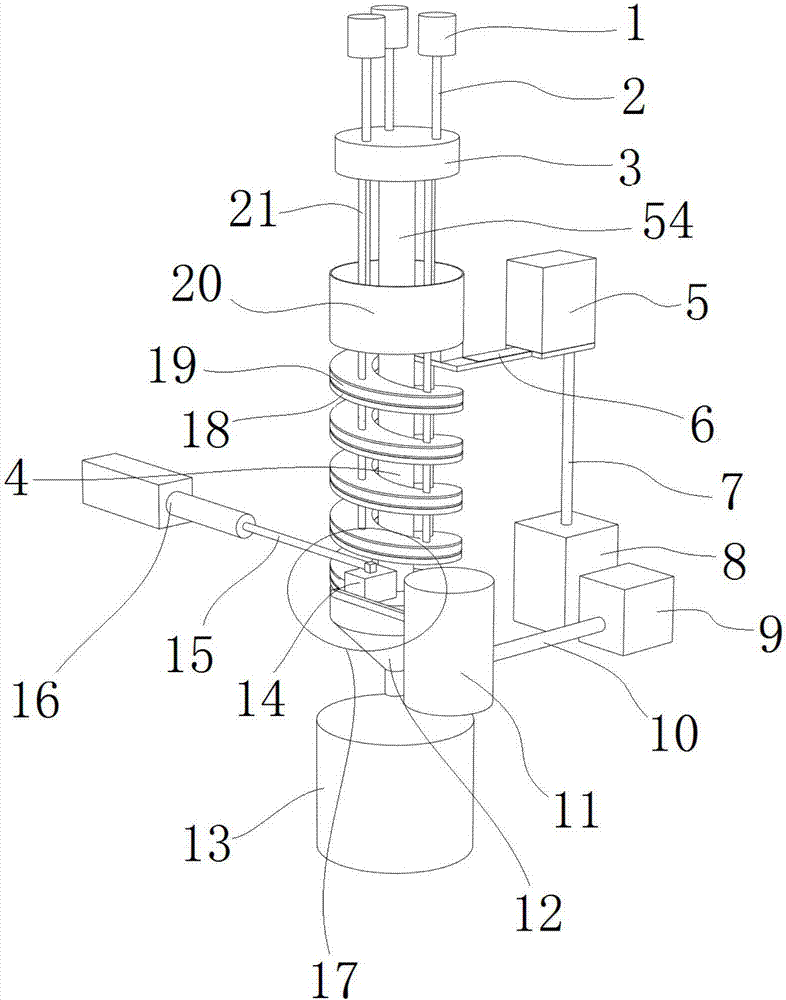

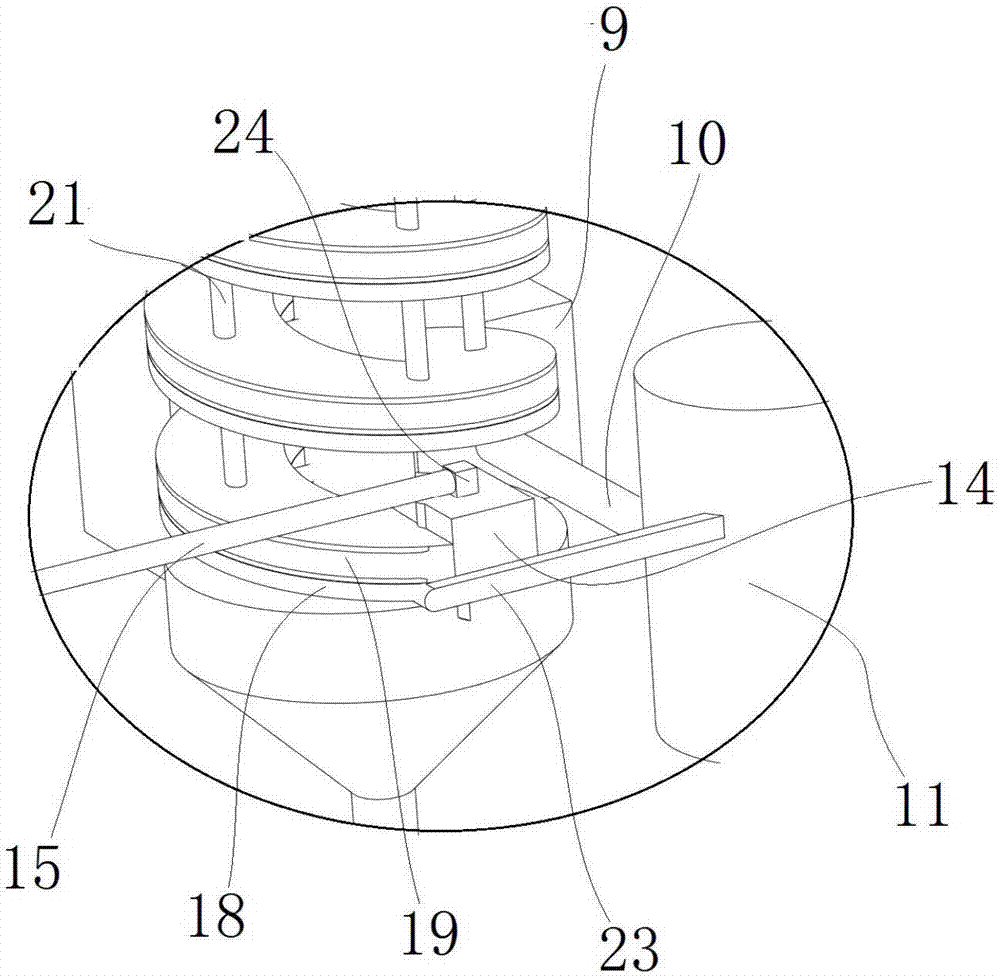

[0035] as attached figure 1 A granular preserved fruit food batching system is shown, comprising a food feed hopper 20, a batching liquid feed hopper 1, a batching liquid mixing unit 3, a batching liquid injection pipe 21, a screw batching pipe 19, a feeding unit 12, a food connection Material tank 13 and vibration unit 4;

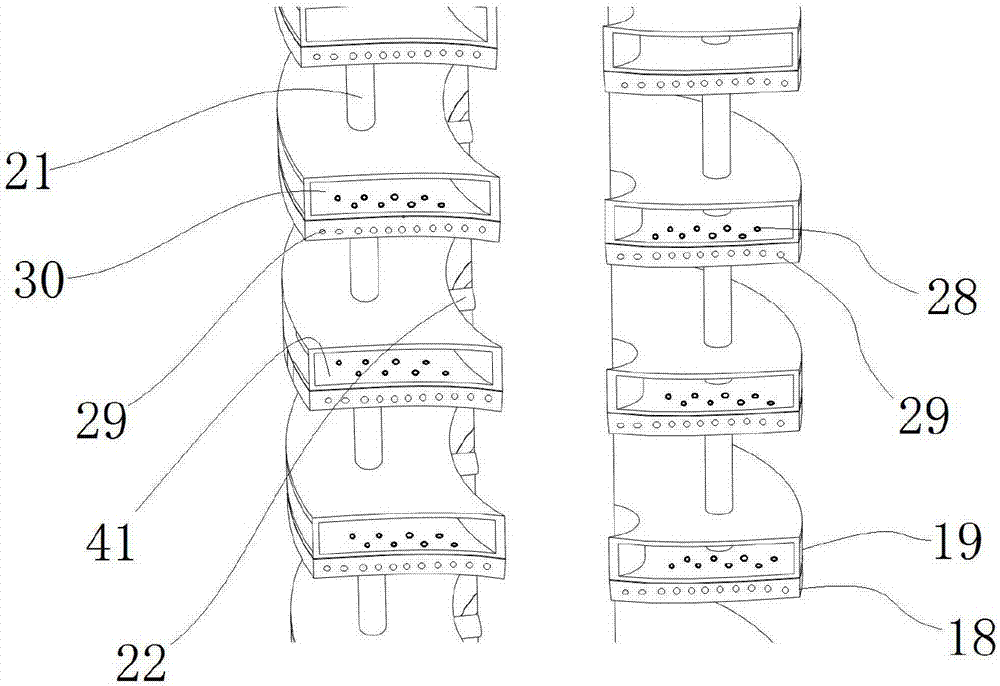

[0036] The spiral batching pipe 19 is coiled on the cylindrical vibration unit 4 in a spiral shape; the discharge end of the food feed hopper 20 is connected to the food inlet at the upper end of the spiral batching pipe 19; the outlet at the lower end of the spiral batching pipe 19 The feed end is communicated with the feed end of the unloading unit 12; the discharge end of the unloading unit 12 is set correspondingly to the feed end of the food receiving tank 13;

[0037]The four vertically arranged batching liquid injection tubes 21 are distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com